Anti-perovskite material with room-temperature magnetic refrigeration performance and preparation method and application thereof

An anti-perovskite, magnetic refrigeration technology, applied in the fields of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of harsh equipment requirements, complex preparation process, harmful raw materials, etc., and achieve excellent stability , huge application potential and prospects, the effect of magnetic transition temperature and saturation magnetization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of an anti-perovskite material with room temperature magnetic refrigeration performance, comprising the following steps:

[0023] (1) According to the molar ratio of Sn:Fe=0.6:3.4, SnO 2 and Fe 2 O 3 Proportioning by weighing, in SnO 2 and Fe 2 O 3 100wt% of absolute ethanol was added to the mixed raw materials for one hour grinding and mixing to obtain a mixed slurry with uniform composition.

[0024] (2) The mixed slurry uniformly mixed in step 1 is dried at 70° C. for two hours in an electric heating blast drying oven, and the dried material is obtained after crushing and grinding.

[0025] (3) Place the material obtained in step 2 in a quartz boat, then put it into a sintering furnace, heat the sintering furnace to make its temperature rise to 650°C, and simultaneously feed the sintering furnace with a gas flow rate of 200 cc / min Ammonia gas is nitriding, and the nitriding time is 15 hours to obtain a pre-phased sample

[0026] (4) After ...

Embodiment 2

[0028] Different from Example 1, SnO in Example 2 2 and Fe 2 O 3 The molar ratio of Sn:Fe is 0.8:3.2, and other preparation processes are the same as in Example 1; the prepared anti-perovskite material is denoted as Sn 0.8 NFe 3.2 .

Embodiment 3

[0030] Different from Example 1, SnO in Example 3 2 and Fe 2 O 3 The molar ratio of Sn:Fe is 1:3, and other preparation processes are the same as in Example 1; the prepared anti-perovskite material is denoted as Sn 1 NFe 3 .

[0031] The samples prepared in the above-described embodiments are tested for performance, and the results are analyzed as follows:

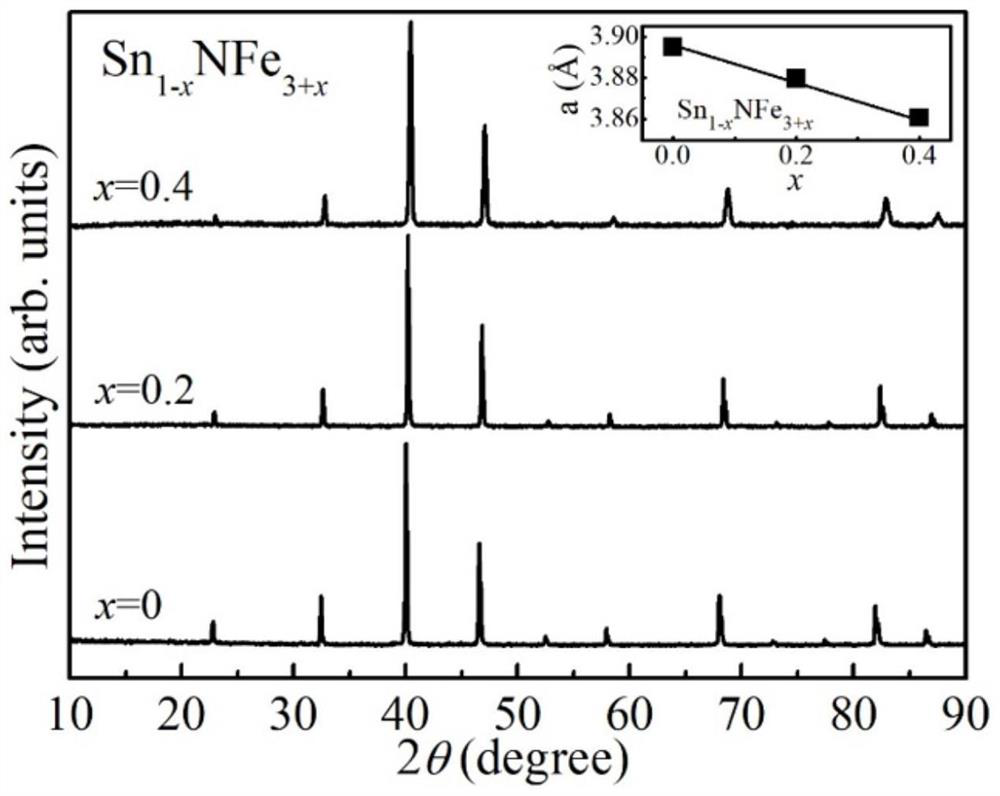

[0032] figure 1 For the XRD patterns of the materials prepared in Examples 1 to 3, from figure 1 It can be seen that the present invention realizes Sn through the doping control of atoms. 1-x NFe 3+x The anti-perovskite doped series samples were prepared, and high-quality pure-phase samples were obtained, and the lattice constants complied with the doping law, showing a linear decreasing trend.

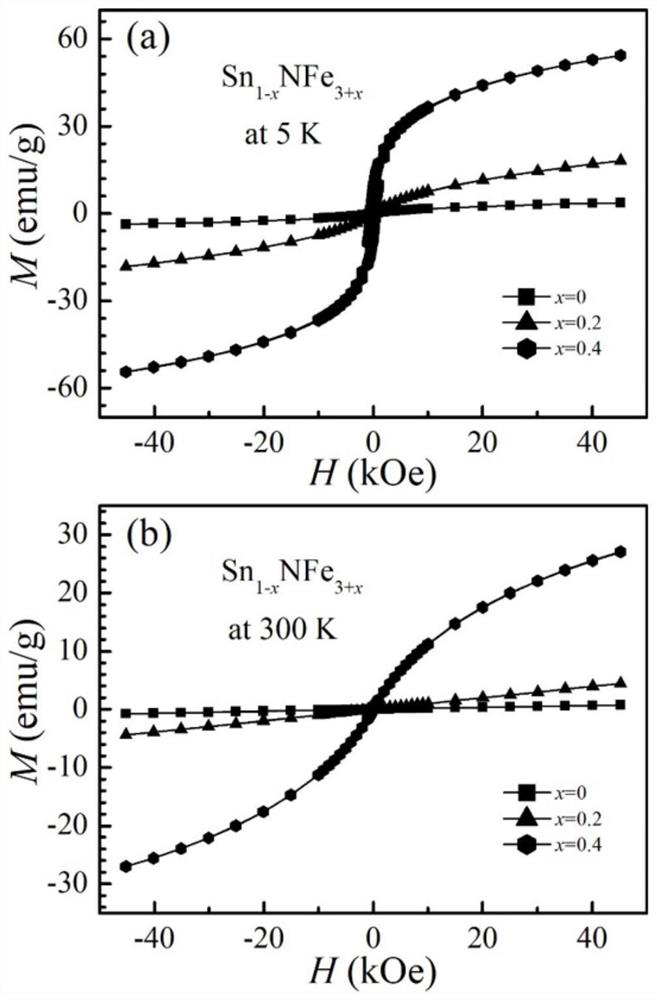

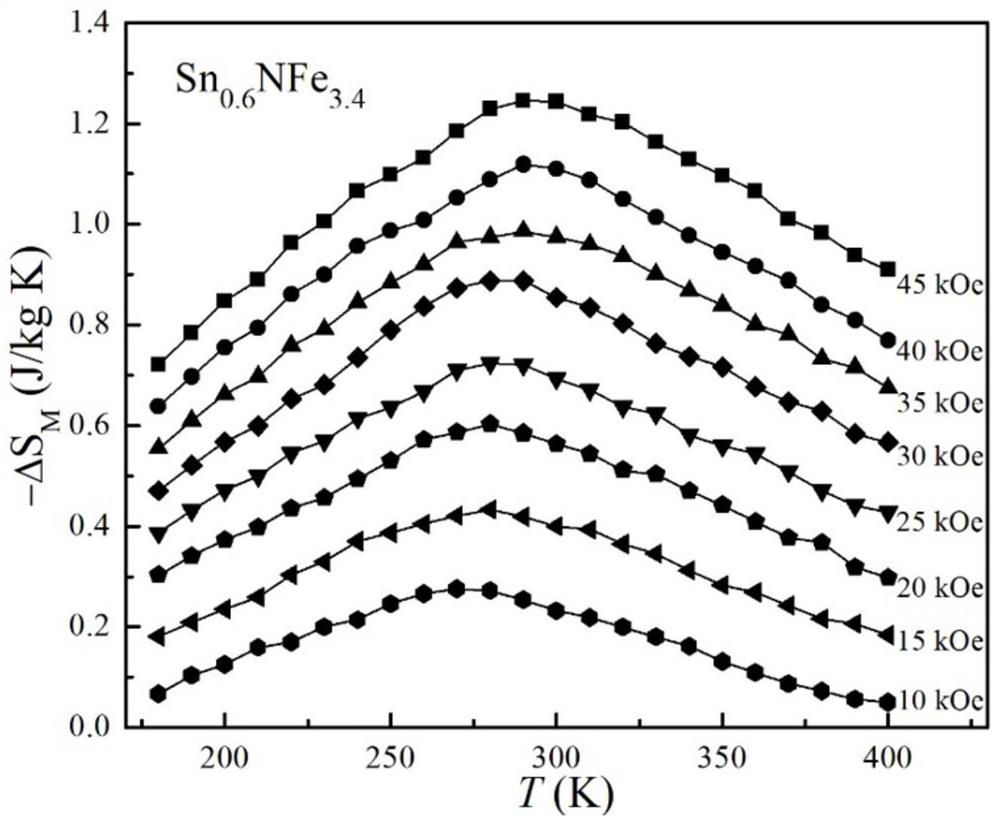

[0033] figure 2 The magnetic performance test results for the materials prepared in Examples 1 to 3 in 5K and 300K environments, respectively, from figure 2 It can be seen that the transformation of the sample from ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum magnetic entropy change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com