High-performance delta-CsPbI3 film memristor and preparation method thereof

A memristor and high-performance technology, applied in the field of high-performance δ-CsPbI3 thin film memristor and its preparation, can solve problems such as SET voltage reduction, and achieve the effects of simple preparation, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

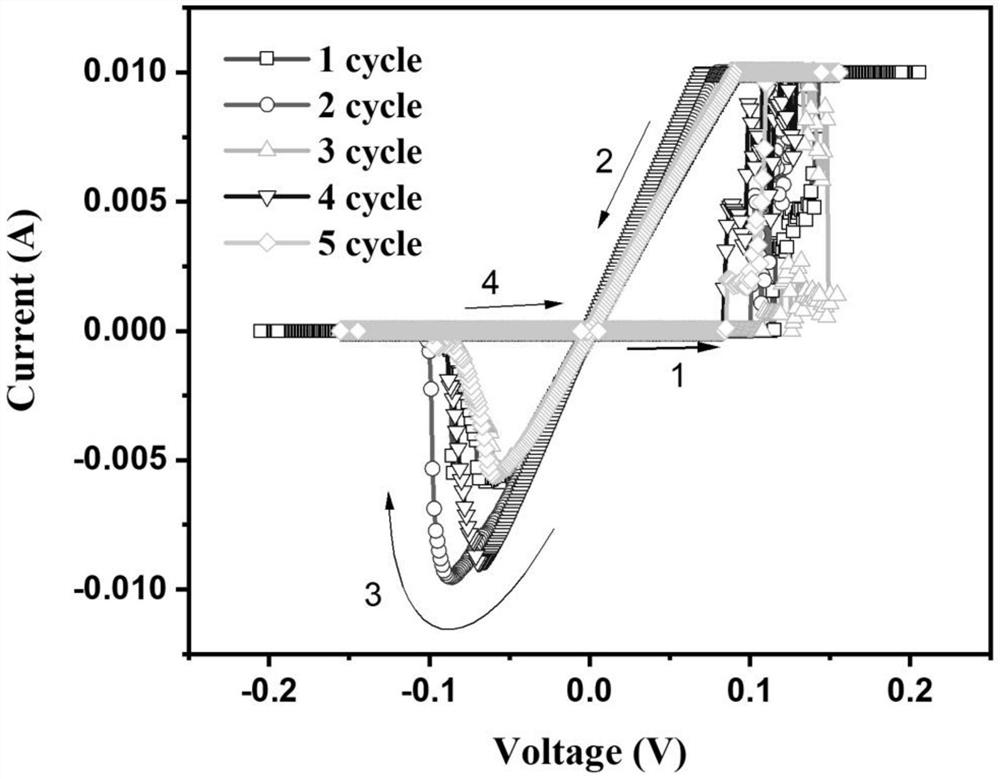

Examples

Embodiment 1

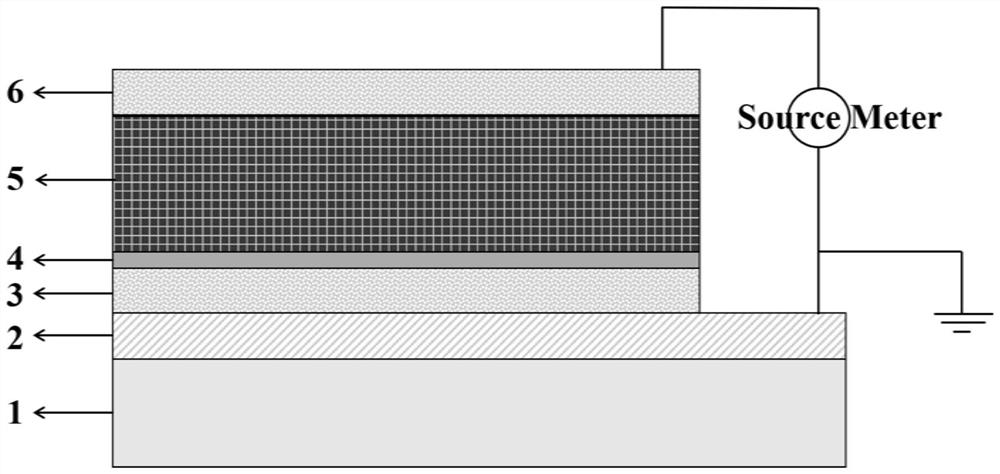

[0039] A high-performance δ-CsPbI 3 The preparation method of thin film memristor comprises the following steps:

[0040] 1) Prepare clean FTO: First prepare the FTO conductive glass substrate composed of glass substrate 1 and FTO film 2, cut the FTO conductive glass into a size of 15mm × 13mm, and perform simple cleaning; then soak it in potassium dichromate In the solution for 20 minutes, clean the potassium dichromate, then wipe the surface with a non-woven fabric with detergent water; ultrasonically clean with deionized water and ethanol for 20 minutes; put the cleaned FTO into vacuum drying Dry in the oven; finally, sintering at 500℃ for 30 minutes in a flat furnace to remove organic impurities on the surface.

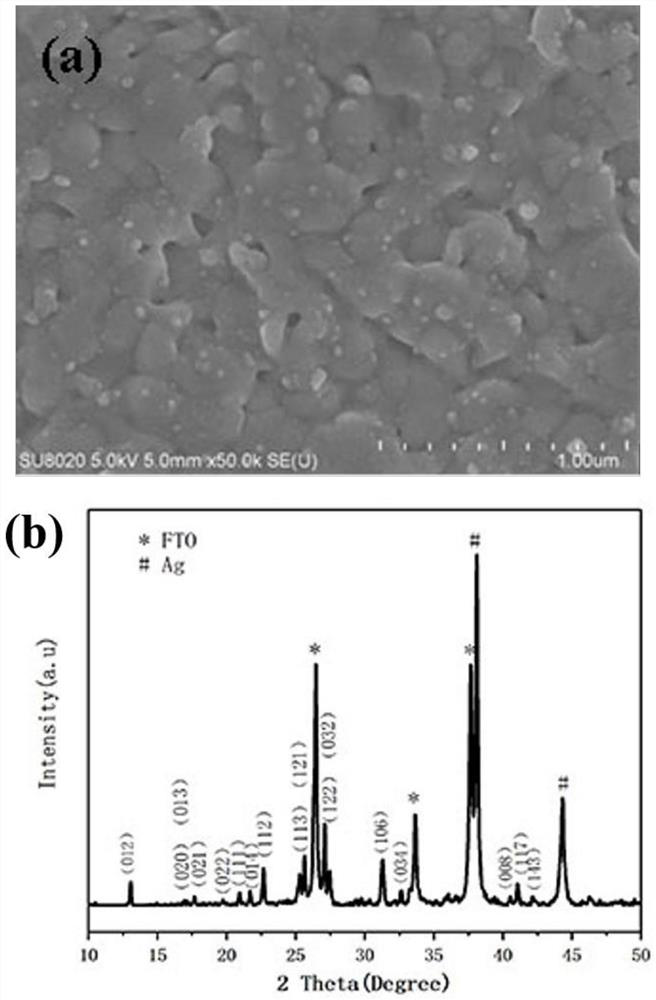

[0041] Evaporating the bottom electrode Ag film 3 on the surface of the FTO conductive glass: due to the appropriate roughness of the FTO, the bonding force of the Ag film can be significantly enhanced. At the same time, the use of the FTO is equivalent to leavin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com