Molded article for laser welding, and inhibitor for fixture of laser transmission in

A molding product, laser melting technology, applied in the field of laser transmittance deviation inhibitor, can solve the problems of low chemical resistance, low heat resistance, limited use, etc., achieve excellent laser transmittance, excellent visible light transmittance, The effect of suppressing bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the preparation of polybutylene terephthalate resin, when an aromatic dicarboxylic acid other than terephthalic acid or an ester-forming derivative thereof is used as a comonomer component, for example, isophthalic acid can be used. , phthalic acid, 2,6-naphthalenedicarboxylic acid, 4,4'-dicarboxydiphenyl ether, etc. C 8-14 aromatic dicarboxylic acids; succinic acid, adipic acid, azelaic acid, sebacic acid, etc. C 4-16 alkane dicarboxylic acid; cyclohexane dicarboxylic acid, etc. C 5-10 cycloalkane dicarboxylic acids; ester-forming derivatives (C 1-6 alkyl ester derivatives, acid halides, etc.). These dicarboxylic acid components can be used individually or in combination of 2 or more types.

[0030] Among these dicarboxylic acid components, C such as isophthalic acid is more preferable 8-12 Aromatic dicarboxylic acids, and adipic acid, azelaic acid, sebacic acid, etc. C 6-12 of alkane dicarboxylic acids.

[0031] In the preparation of polybutylene terephthalat...

Embodiment 1、 comparative example 1~9

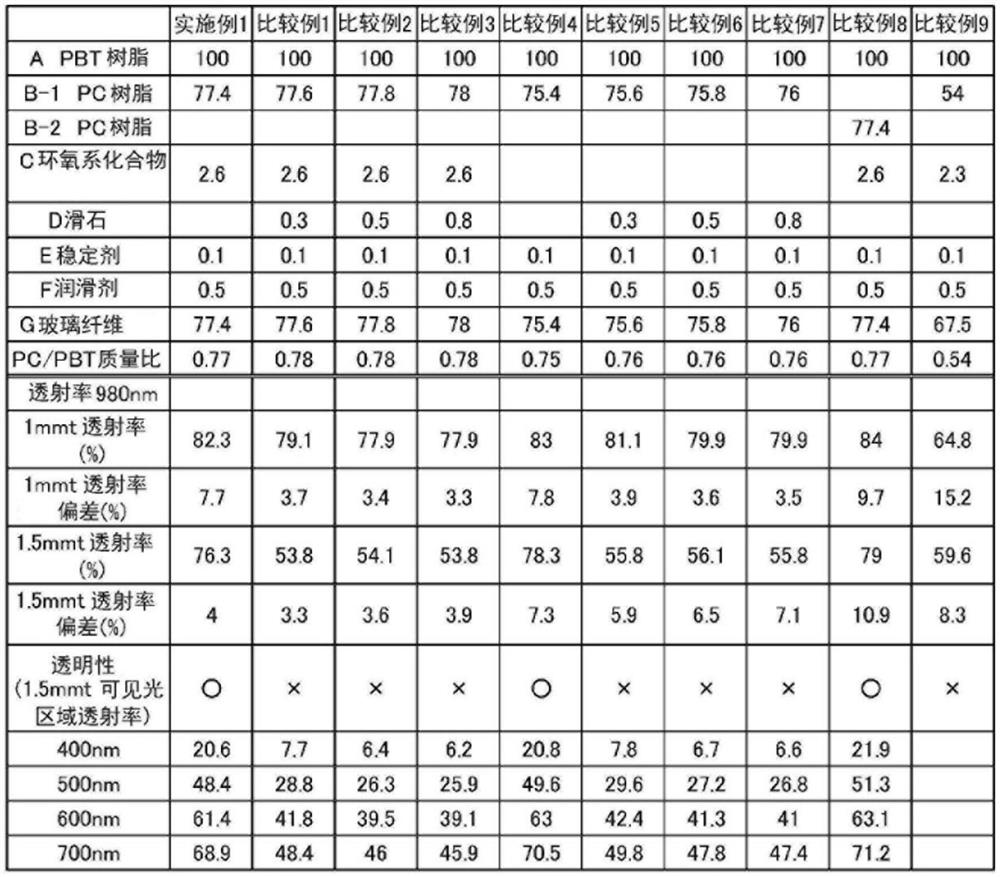

[0097] With respect to 100 parts by mass of (A) polybutylene terephthalate resin, after mixing each component in the ratio shown in Table 1, using TEX30 manufactured by Nippon Steel Works, the barrel temperature was 260°C, and the discharge amount was 15kg / It melt-kneaded and extruded at the screw rotation speed of 130 rpm, and obtained the pellet which consists of a polybutylene terephthalate resin composition. Then, a test piece of 80 mm×80 mm×1 mmt or 1.5 mmt was produced from the pellets by injection molding using an injection molding machine S-2000i100B manufactured by FANUC Corporation, and the light transmittance (%) at a wavelength of 980 nm and the wavelengths of 400 nm, 500 nm, and 600 nm were measured. , Measurement of light transmittance (%) of various test pieces at 700 nm. The results are shown in Table 1.

[0098] [Table 1]

[0099]

[0100] As shown in Table 1, when the thickness of the product was increased, the effect of suppressing the variation in tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com