Absorbable stent

A technology for supporting rods and substrates, used in stents, medical science, coatings, etc., can solve the problems of poor mechanical properties, slow corrosion rate, and difficult absorption of corrosion products, and achieve the effect of short corrosion and absorption cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

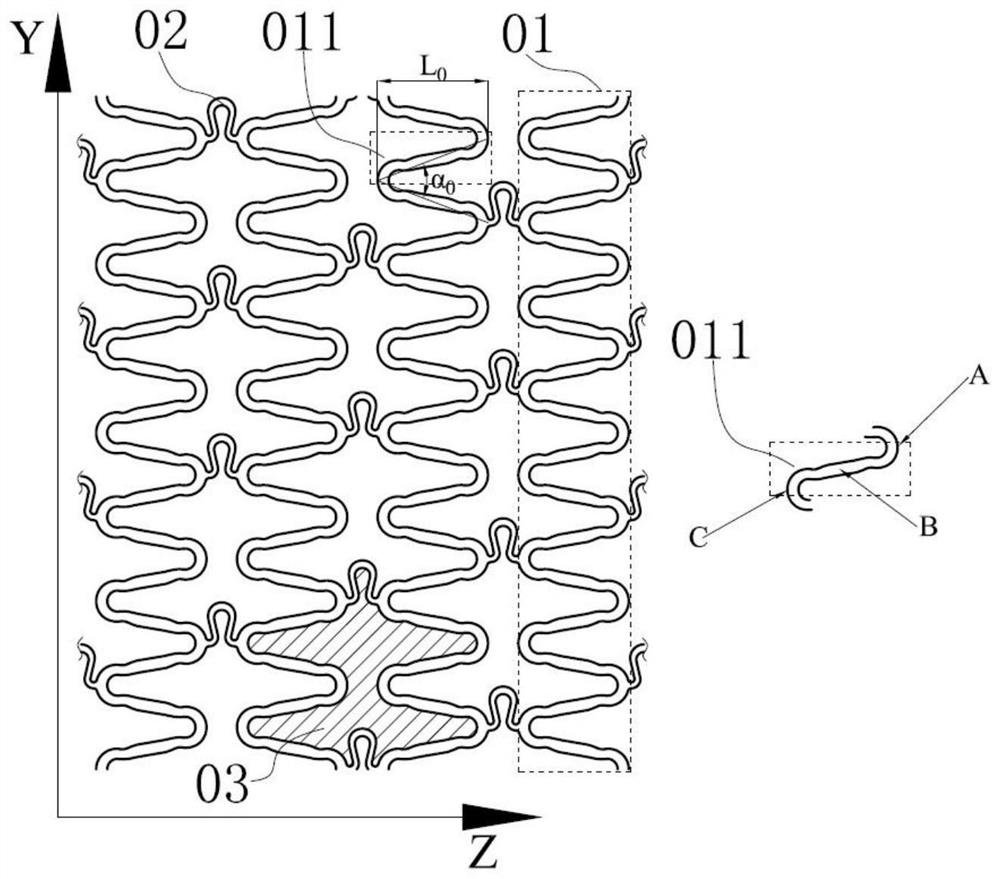

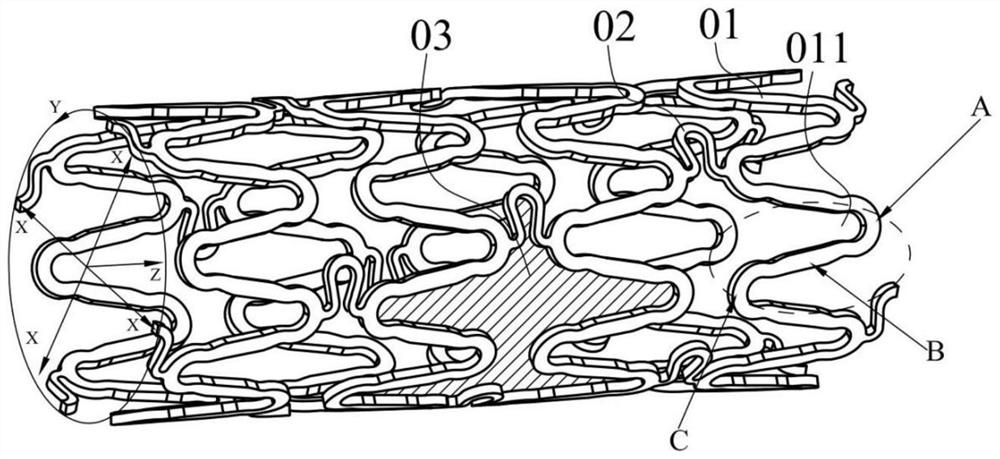

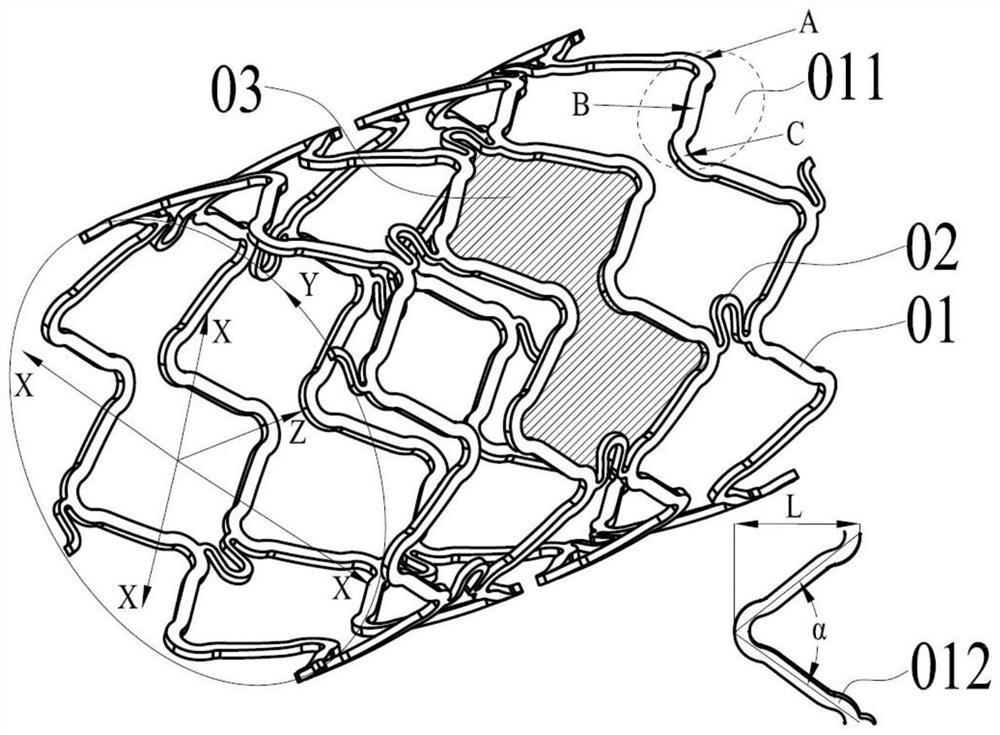

[0086] see also Figures 1 to 3 , an absorbable coronary stent, the base material is nitrided iron, the base includes a plurality of wave circles 01 connected by connecting units 02 and arranged in the axial direction, two adjacent wave circles 01 and connecting units 02 are formed In the closed side branch unit 03, the wave circle 01 is composed of a plurality of waveforms 011 arranged in the circumferential direction.

[0087] The polishing allowance of the preform with the predetermined matrix structure obtained by cutting the nitrided iron tube with an outer diameter of 1.3 mm is 0.025 mm; after the preform is polished to absorb the stent 100, the wall thickness of the support rod B of the stent 100 is 0.038 mm , the rod width is 0.076mm, and the rod width is uniform.

[0088] The ratio of the rod width to the wall thickness of the support rod B is 2.0, the number A of wave circles 01 is 28, the number B of connecting units 02 between adjacent wave circles 01 is 3, and th...

Embodiment 2

[0092] See Figure 7 , the matrix material of the absorbable coronary vascular stent in this embodiment is iron nitride, which has a similar structure to the matrix of the absorbable coronary vascular stent in Example 1. The differences are:

[0093] The polishing allowance of the preform with a predetermined matrix structure obtained by cutting a nitrided iron tube with an outer diameter of 1.6 mm is 0.030 mm; after the preform is polished into an absorbable stent 200, the wall thickness of the support rod of the stent is 0.052 mm, and the wave shape is 0.052 mm. 211 as Figure 7 As shown, the rod width varies between [0.074, 0.091] mm.

[0094] The ratio of the rod width to the wall thickness of the support rod is [1.42, 1.75], the number A of wave circles is 15, the number B of connecting units between adjacent wave circles is 4, and the number C of waves contained in the wave circles is 16. The included angle α0 of the support rod is 41.5°, and the section length L0 of t...

Embodiment 3

[0098] The base material of the absorbable coronary stent in this embodiment is iron nitride, which has a similar structure to the base of the absorbable coronary stent in Embodiment 2. The difference is that the structure of the connecting unit 52 of the stent is as follows: Image 6 As shown in , the wall thickness of the support rods of this stent was reduced to 0.047 mm.

[0099] Implanted in a 3.0mm lumen, the radial support strength of the absorbable coronary stent is 120kPa, which is the same as the radial support strength of the absorbable coronary stent in Example 2, but the absorbable coronary stent has the same radial support strength as the absorbable coronary stent in Example 2. The volume per unit vessel area of the stent was lower at 6.4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com