Manufacturing method for full-automatic rapid formaldehyde-free adding and pressing veneer veneer plywood

A manufacturing method and technology of plywood, applied in the jointing of wooden veneers, other plywood/plywood utensils, manufacturing tools, etc., can solve the problems of excessive formaldehyde emission, poor process continuity, and low work efficiency of plywood, and achieve increased The effect of contact area, improving efficiency and saving glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

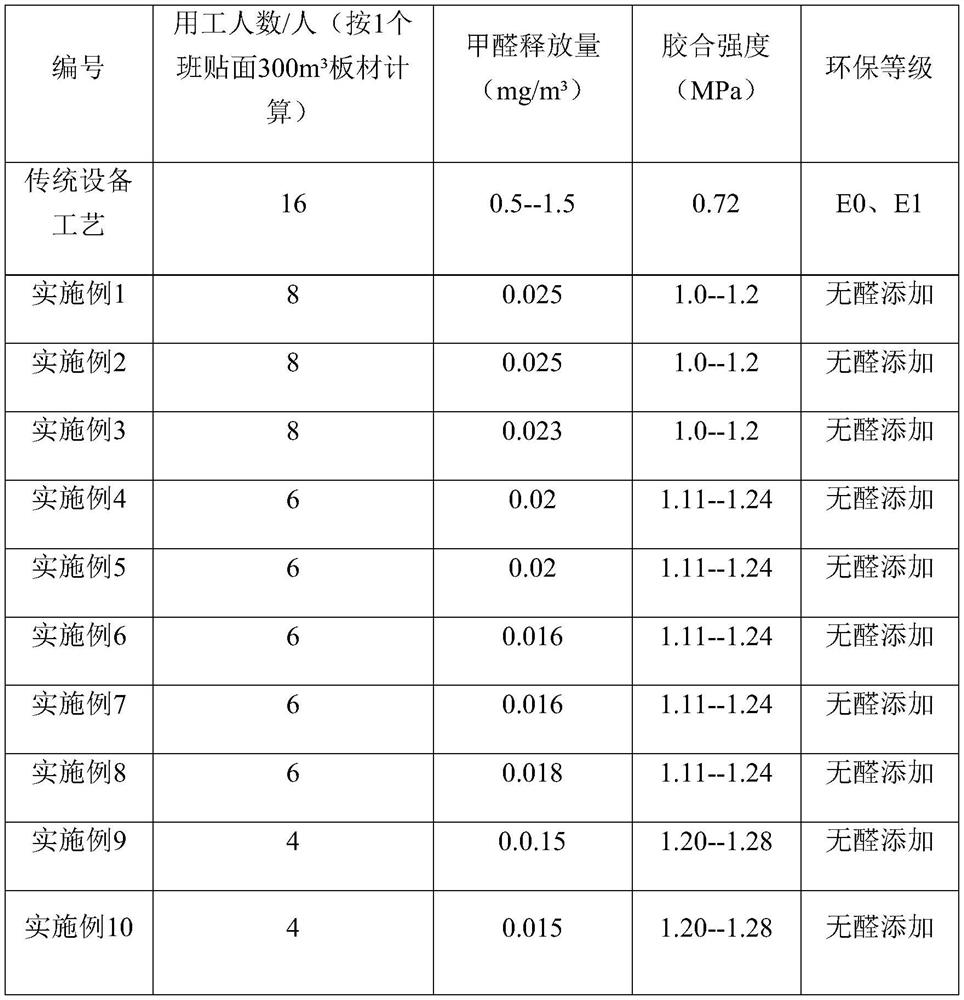

Examples

Embodiment 1

[0033] A fully automatic and fast formaldehyde-free addition and lamination manufacturing method of veneer veneer plywood, comprising the following steps:

[0034] S1. The aldehyde-free added plywood substrate is prepared by continuous hot pressing on the main line, and then maintained for 5 days. After the stress of the aldehyde-free added plywood substrate is released, one-time double-sided sanding and two sets of single-sided sanding are used for fixed-thickness sanding;

[0035] S2. Stack the above-mentioned aldehyde-free added plywood base material and use it as a gluing material, use veneer as a veneer material, and then use a sizing roller to apply isocyanate on the surface of the veneer material, and then paste it on the gluing material in turn. On the material, a veneer blank is formed, wherein the veneer can be any one of mahogany, sapele, ash, birch and beech, and the thickness of the veneer is 0.2mm, the moisture content is 8%, and the density is >0.65 Kg / m 3 ;

...

Embodiment 2

[0042] A fully automatic and fast formaldehyde-free manufacturing method for adding and pressing veneer veneer plywood, comprising the following steps:

[0043] S1. The aldehyde-free added plywood substrate is prepared by continuous hot pressing of the main line, and then maintained for 6 days. After the stress of the aldehyde-free added plywood substrate is released, one-time double-sided sand and two sets of single-sided sanding are used for fixed-thickness sanding;

[0044] S2. Stack the above-mentioned aldehyde-free added plywood base material and use it as a gluing material, use veneer as a veneer material, and then use a sizing roller to apply isocyanate on the surface of the veneer material, and then paste it on the gluing material in turn. On the material, a veneer blank is formed, wherein the veneer can be any one of mahogany, sapele, ash, birch and beech, and the thickness of the veneer is 0.4mm, the moisture content is 10%, and the density is >0.65 Kg / m 3 ;

[004...

Embodiment 3

[0051] A fully automatic and fast formaldehyde-free manufacturing method for adding and pressing veneer veneer plywood, comprising the following steps:

[0052] S1. Prepare the aldehyde-free plywood substrate by continuous hot pressing on the main line, and then keep it for 7 days. After the stress of the aldehyde-free plywood substrate is released, use one double-sided sand and two sets of single-sided sanding for fixed thickness sanding;

[0053] S2. Stack the above-mentioned aldehyde-free added plywood base material and use it as a gluing material, use veneer as a veneer material, and then use a sizing roller to apply isocyanate on the surface of the veneer material, and then paste it on the gluing material in turn. On the material, a veneer blank is formed, wherein the veneer can be any one of mahogany, sapele, ash, birch and beech, and the thickness of the veneer is 0.6mm, the moisture content is 12%, and the density is >0.65 Kg / m 3 ;

[0054] S3. The above-mentioned ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com