Ectopic gas stripping type circulating water purification culture system applying electric flocculation technology

A breeding system, electric flocculation technology, applied in the field of ex-situ airlift circulating water purification breeding system, can solve the problems of high cost, easy blockage of filter screen, etc., and achieve high water purification efficiency, low equipment energy consumption, and compact system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

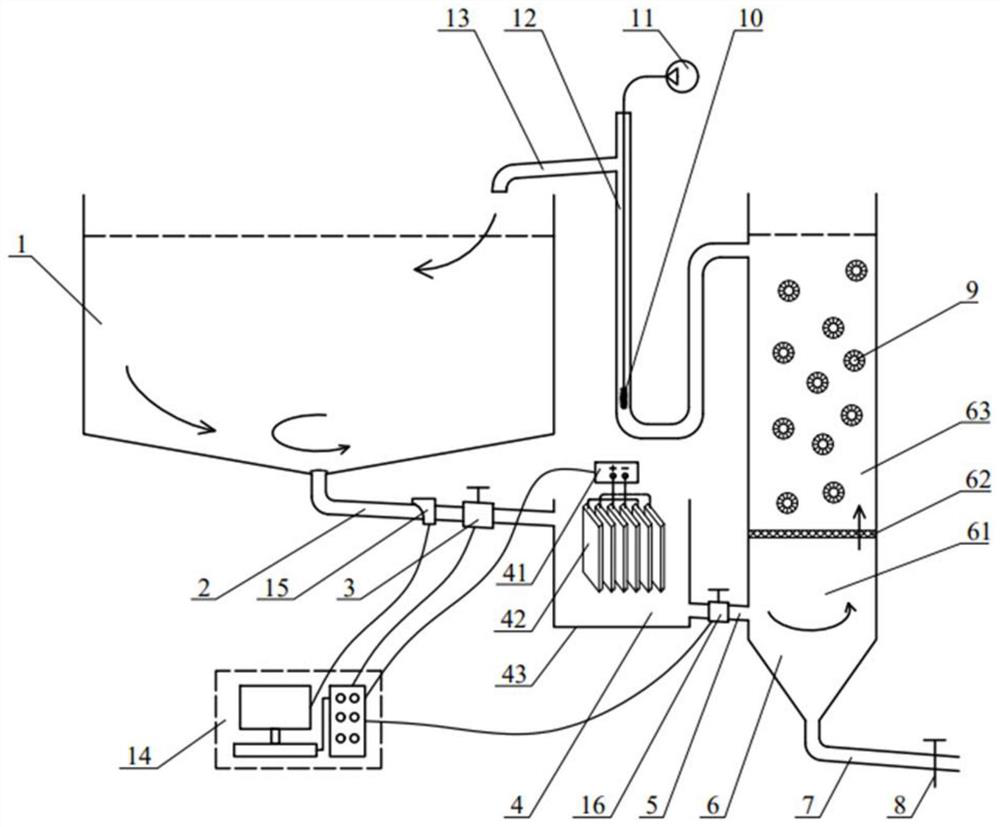

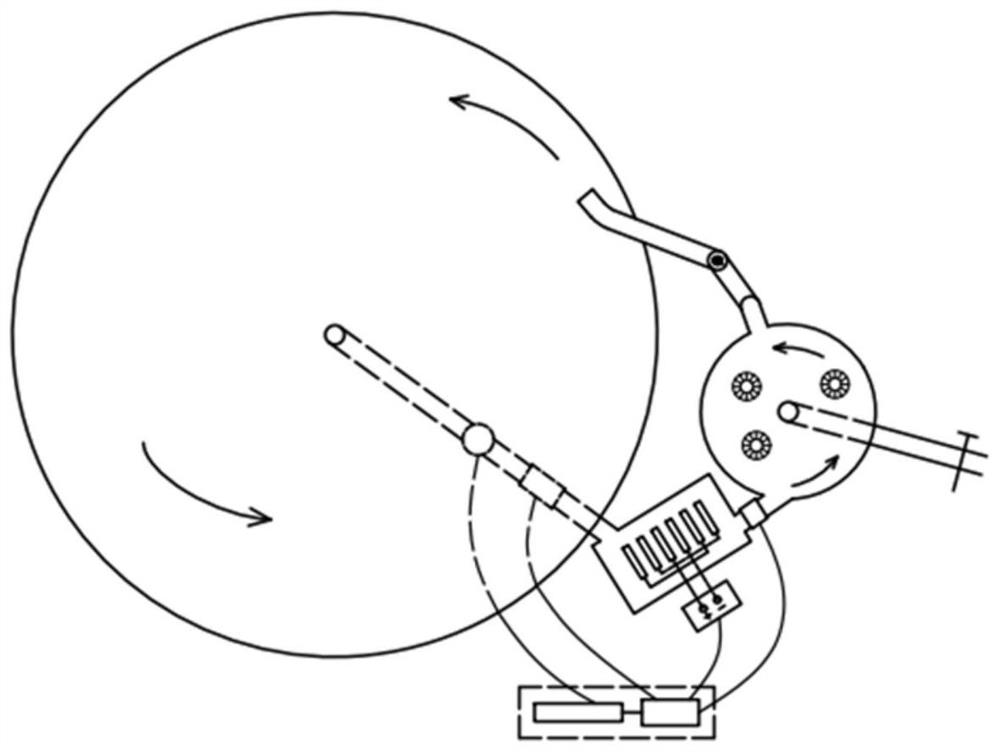

[0030] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and specific examples.

[0031] figure 1 The example shown is an off-site air-lifting circulating water purification culture system using electro-flocculation technology of the present invention, including a culture pond 1, an electro-flocculation device 4, a water-purifying sewage collecting device 6, a sewage pipe 7, and an air-lifting device. (including the air stripping pipe 12 and the air stripping water pipe 13) and the intelligent display control device 14, wherein the electric flocculation device 4 and the air stripping device are the main features of the system, and the intelligent display control device 14 combined with the electric flocculation device 4 is a unique setting of the system.

[0032] Each of the culturing ponds 1 is configured with an electric flocculation device 4 and a water purification sewage collection device 6. The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com