Preparation method of silicon-aluminum-based cementing material, silicon-aluminum-based cementing material and application of silicon-aluminum-based cementing material

A cementitious material, silicon-aluminum-based technology, applied in cement production, carbon capture, etc., can solve the problems of site occupation, salinization, loss of salt and impurities, etc., to reduce carbon emissions, reduce carbon content, and long life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

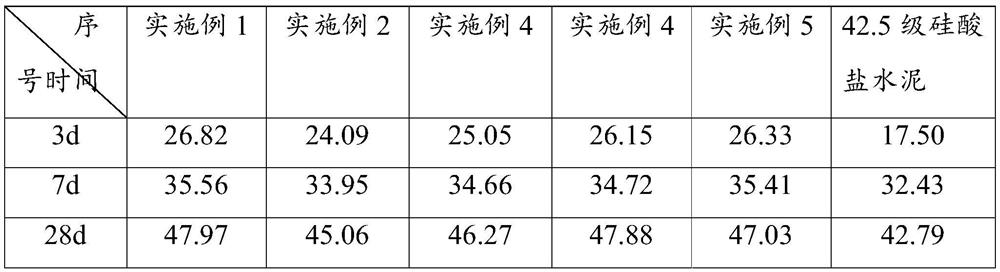

Embodiment 1

[0029] A preparation method of a silica-alumina-based cementitious material, comprising the following steps:

[0030] Step 1: In terms of mass percentage, the raw materials include 39% of slag, 28% of waste concrete, 15% of fly ash, 10% of calcined industrial waste salt, 3.5% of coal gangue, 2% of tailings, and 2.5% of waste glass The raw materials are respectively loaded into the raw material warehouse;

[0031] Step 2: The waste concrete, fly ash, and industrial waste salt calcined and pyrolyzed at 1000°C for 18 hours in step 1 are conveyed to the ring roller mill through the conveyor belt under the hopper, and the slag, tailings, waste glass, and coal gangue are passed through The conveyor belt under the hopper is conveyed to the vertical grinding equipment, and the ground is uniformly ground to a specific surface area of 420m 2 / kg of coarse material, and then transported to the material tank by the bucket elevator for standby;

[0032] Step 3: The coarse material in s...

Embodiment 2

[0036] A preparation method of a silica-alumina-based cementitious material, comprising the following steps:

[0037] Step 1: In terms of mass percentage, the raw materials include 30% of slag, 35% of waste concrete, 10% of fly ash, 15% of calcined industrial waste salt, 5% of coal gangue, 3% of tailings, and 2% of waste glass The raw materials are respectively loaded into the raw material warehouse;

[0038] Step 2: The waste concrete, fly ash, and industrial waste salt calcined and pyrolyzed at 1250°C for 6 hours in step 1 are conveyed to the ring roller mill through the conveyor belt under the hopper, and the slag, tailings, waste glass, and coal gangue are passed through The conveyor belt under the hopper is conveyed to the vertical grinding equipment, and the ground is uniformly ground to a specific surface area of 420m 2 / kg of coarse material, and then transported to the material tank by the bucket elevator for standby;

[0039] Step 3: The coarse material in step 2...

Embodiment 3

[0043] A preparation method of a silica-alumina-based cementitious material, comprising the following steps:

[0044] Step 1: In terms of mass percentage, the raw materials include 45% of slag, 21% of waste concrete, 20% of fly ash, 7% of calcined industrial waste salt, 2% of coal gangue, 1% of tailings, and 4% of waste glass The raw materials are respectively loaded into the raw material warehouse;

[0045] Step 2: Transfer the waste concrete, fly ash, and industrial waste salt that has been pyrolyzed at 1100°C for 12 hours in step 1 to the ring roller mill through the conveyor belt below the hopper, and transfer the slag, tailings, waste glass, and coal gangue to the ring roller mill. The conveyor belt under the hopper is conveyed to the vertical grinding equipment, and the ground is uniformly ground to a specific surface area of 420m 2 / kg of coarse material, and then transported to the material tank by the bucket elevator for standby;

[0046] Step 3: The coarse materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com