Anti-fogging TPU (Thermoplastic Polyurethane) film for automobile film and preparation process of anti-fogging TPU film

A technology of car film sticking and preparation process, which is applied in the field of TPU film, can solve the problems of non-corrosion resistance, foggy surface of TPU film, and reduced safety, so as to improve anti-fog performance, corrosion resistance performance and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

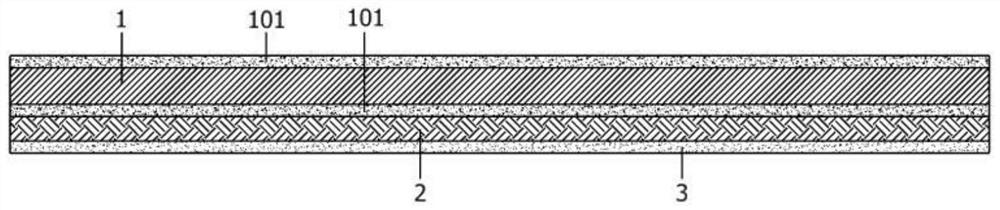

[0038] Example: please refer to figure 1 :

[0039] The present invention provides an anti-fog TPU film for car sticking film and a preparation process thereof, including: a TUP film base layer 1, and the TUP film base layer 1 is composed of the following raw materials: TUP resin, anti-fog performance generating raw material composition, corrosion resistance performance generating Raw material composition and microbial degradation performance generating raw material composition; the anti-fog raw material composition includes the following components: acrylate rubber, water-absorbing resin, filler, wherein the filler is diatomaceous earth;

[0040] Among them, acrylate rubber is an elastomer obtained by copolymerization of acrylate as the main monomer. Its main chain is a saturated carbon chain, and its side groups are polar ester groups. Due to its special structure, it endows it with many excellent characteristics, such as resistance to Heat, aging resistance, oil resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com