Preparation method of velvet-shaped night indication woven belt capable of generating power

A technology of night indication and webbing, applied in wind power generation, textiles, fabrics, etc., can solve problems such as inability to provide clear enough information, weaken flexibility and portability, and inability to provide light-emitting elements, and achieve poor flexibility and controllable density. , to solve the effect of large voltage output loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of a velvet night indicating woven belt capable of generating electricity, the specific steps are as follows:

[0047] (1) Preparation of piezoelectric monofilament;

[0048] (1.1) Preparation of raw materials;

[0049] Elastomer chip: The elastomer is polystyrene-ethylene-butadiene-styrene block copolymer, the manufacturer is Taiwan Rubber (Shanghai) Industrial Co., Ltd., and the brand name is SEBS-6152;

[0050] The conductive yarn I is a copper fiber spun fiber yarn, and the copper fibers constituting the copper fiber spun fiber yarn have an average diameter of 12 μm and an average length of 80 mm;

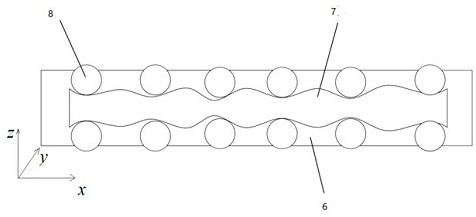

[0051] Piezoelectric film I: First, a mixture consisting of polyvinylidene fluoride-trifluoroethylene, barium titanate with an average particle size of 170 nm and dimethylformamide was prepared, then the mixture was coated on the substrate to form a film, and finally the film was Carry out hot pressing treatment to give it a wavy band structure, an...

Embodiment 2

[0064] A preparation method of a velvet night indicating woven belt capable of generating electricity, the specific steps are as follows:

[0065] (1) Preparation of piezoelectric monofilament;

[0066] (1.1) Preparation of raw materials;

[0067] Elastomer chip: The elastomer is polystyrene-ethylene-butadiene-styrene block copolymer, the manufacturer is Taiwan Rubber (Shanghai) Industrial Co., Ltd., and the brand name is SEBS-6152;

[0068] The conductive yarn I is a copper fiber spun fiber yarn, and the copper fibers constituting the copper fiber spun fiber yarn have an average diameter of 14 μm and an average length of 70 mm;

[0069] Piezoelectric film I: First prepare a mixture consisting of polyvinylidene fluoride (manufactured by Shandong Huaxia Shenzhou New Materials Co., Ltd., brand DS202), barium titanate with an average particle size of 180 nm, and dimethylformamide, and then the mixture is It is coated on the substrate to form a film, and finally the film is subj...

Embodiment 3

[0082] A preparation method of a velvet night indicating woven belt capable of generating electricity, the specific steps are as follows:

[0083] (1) Preparation of piezoelectric monofilament;

[0084] (1.1) Preparation of raw materials;

[0085] Elastomer chip: The elastomer is polystyrene-ethylene-butadiene-styrene block copolymer, the manufacturer is Taiwan Rubber (Shanghai) Industrial Co., Ltd., and the brand name is SEBS-6152;

[0086] The conductive yarn I is a copper fiber spun fiber yarn, and the copper fibers constituting the copper fiber spun fiber yarn have an average diameter of 17 μm and an average length of 60 mm;

[0087] Piezoelectric film I: First, a mixture consisting of polyvinylidene fluoride-trifluoroethylene, lead titanate with an average particle size of 190 nm, and dimethylformamide was prepared, and then the mixture was coated on the substrate to form a film. Carry out hot pressing treatment to give it a wavy band structure, and carry out polarizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com