Method for preparing high-purity vanadyl sulfate solution with assistance of microbubbles

A technology of vanadyl sulfate solution and vanadyl sulfate, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve problems such as complex process, waste water generation, unfavorable clean production of vanadyl sulfate solution, etc., and achieve simple process steps , The effect of easy operation of the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

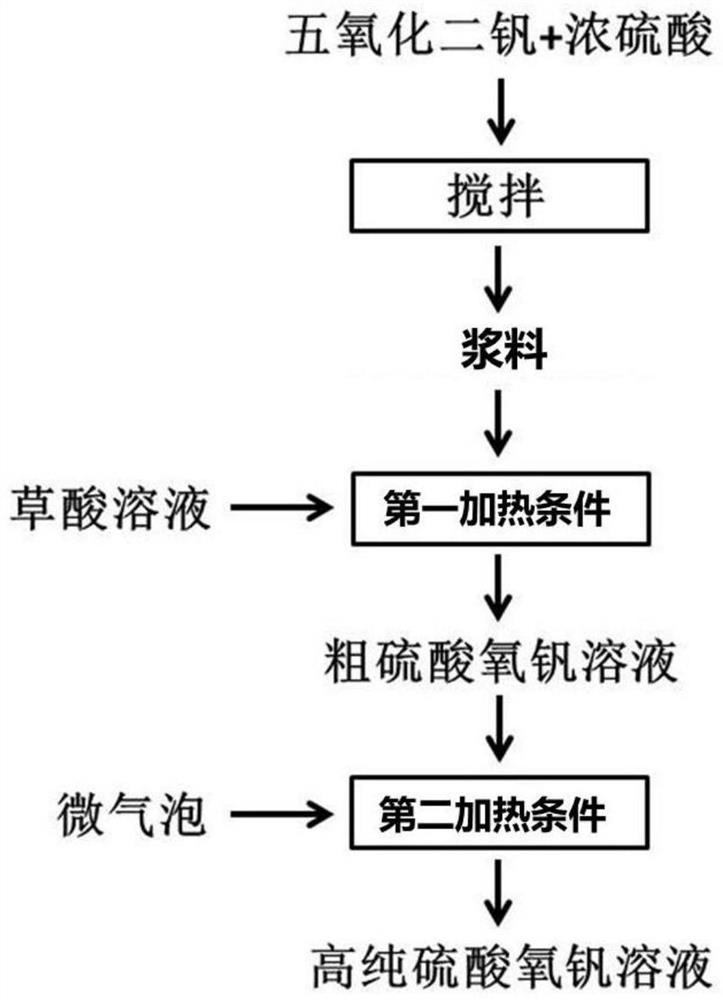

[0043] This embodiment provides a method of micro -foam assistance to prepare high -pure sulfuric acid oxygenic solution, which includes the following steps:

[0044] (1) Mixing 1.6mol five oxidation two -钒 钒 and 5mol sulfuric acid with a mass score of 60 % concentrated sulfuric acid, mixed at room temperature (25 ° C) and stirred 0.6h to make pulp;

[0045] (2) The oxalic acid solution and the hybridic acid solution and the pulp with a mixed concentration of 0.6 mol / L are 1: 1.1 with the oxalic acid Murbal and the reaction of 1.5h at 90 ° C.

[0046] (3) The aeration head with a pore diameter of 0.6 μm is used to pass the air micro -foam in the coarse sulfate oxygate solution, and the aeration reaction is 1h at 50 ° C to obtain a high -pure sulfate oxygenic solution.

Embodiment 2

[0048] This embodiment provides a method of micro -foam assistance to prepare high -pure sulfuric acid oxygenic solution, which includes the following steps:

[0049] (1) Mixed 2.6mol five oxidation two -钒 钒 and 8mol sulfuric acid with a mass score of 70 % concentrated sulfuric acid, mixed at room temperature (25 ° C) and stirred 0.7h to make pulp;

[0050] (2) The oxalic acid solution and the hybridic acid solution and the pulp with a mixed concentration of 0.9 mol / L. The five oxidation and the oxalic acid Murbi ratio is 1: 1.05, and the reaction of 80 ° C is 1h to obtain a coarse sulfuric acid solution;

[0051] (3) The aeration head with a pore diameter of 0.7 μm is used to pass the air micro -foam in the coarse sulfate oxygate solution, and the aeration reaction is 0.8h at 60 ° C.

Embodiment 3

[0053] This embodiment provides a method of micro -foam assistance to prepare high -pure sulfuric acid oxygenic solution, which includes the following steps:

[0054] (1) Mixed 2.3mol five oxidation two -钒 钒 and 7mol sulfuric acid with a mass score of 90 % concentrated sulfuric acid. Mix it at room temperature (20 ° C) and stir for 1h to make a slurry;

[0055] (2) The oxalic acid solution and the hybridic acid solution and the pulp with a mixed concentration of 0.9 mol / L are 1: 1.2 with the oxalic acid Murbal, and the reaction of 80 ° C is 2h.

[0056] (3) The aeration head with a pore diameter of 0.9 μm is used to pass the air micro -bubbles into the coarse sulfate oxygate solution, and the aeration reaction is 0.8h at 60 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com