Deep fluorine removal process for fluorine-containing wastewater and aluminum source fluorine removal agent

A technology for defluoridation agent and waste water, which is applied in the direction of energy waste water treatment, water/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problems of increasing sludge production, difficulty in separation, and difficulty in meeting waste water standards, so as to improve the treatment effect, Reduce the effect of environmental influence factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

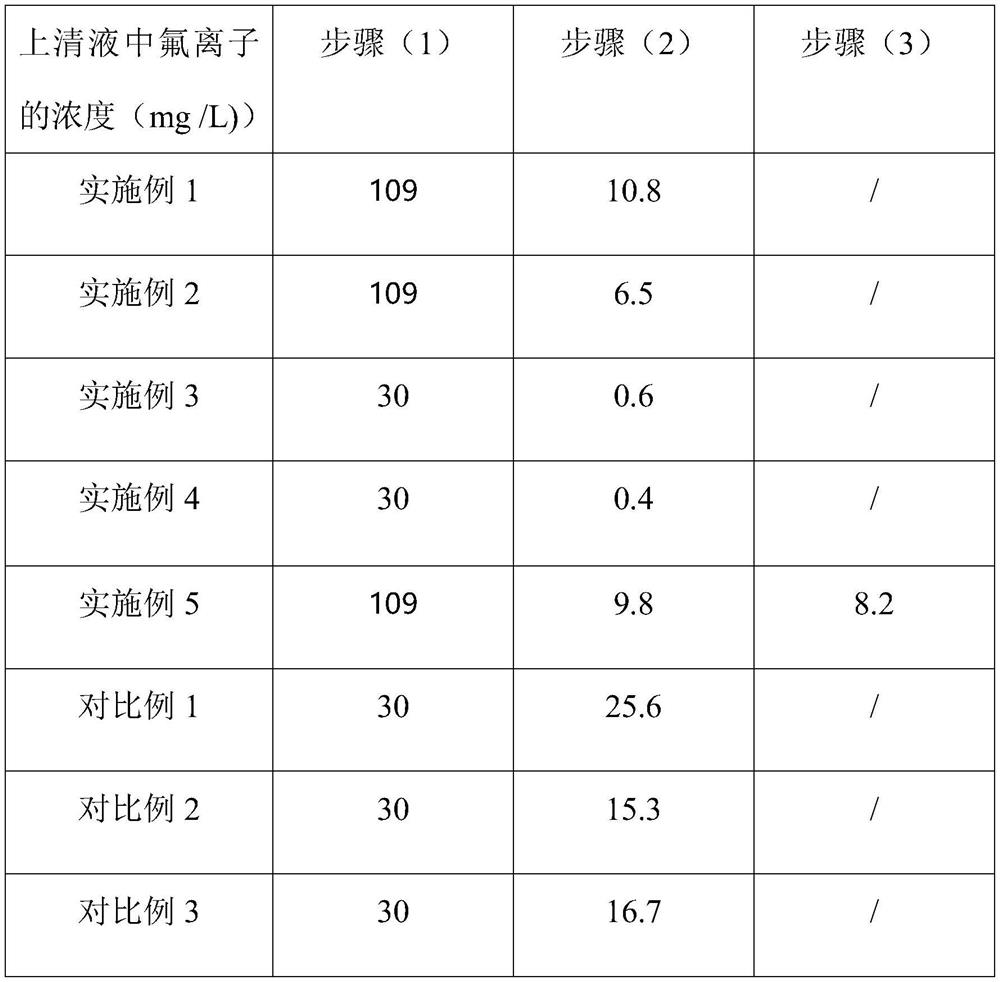

Embodiment 1

[0034] The deep defluorination process of a kind of fluorine-containing wastewater proposed in this embodiment includes the following steps:

[0035] (1) after the pH value of fluorine-containing waste water (the concentration of fluoride ion is 9300mg / L) is adjusted to 7-8, it is introduced into the first reaction tank, and calcium carbide slag is added to the first reaction tank, and the dosage of calcium carbide slag is 50g / L, stir and mix the fluorine-containing wastewater for 0.5h, and measure the concentration of fluoride ions in the supernatant of the first reaction tank;

[0036] (2) after the pH value of the supernatant liquid obtained in step (1) is adjusted to 6.8, the second reaction tank is introduced into the second reaction tank, and an aluminum source defluorinating agent is added to the second reaction tank, and the dosage of the aluminum source defluorinating agent is 1.5g / L, after stirring and mixing the fluorine-containing wastewater for 0.5h, the concentra...

Embodiment 2

[0040] The deep defluorination process of a kind of fluorine-containing wastewater proposed by the present embodiment comprises the following steps:

[0041] (1) after the pH value of fluorine-containing wastewater (the concentration of fluoride ion is 9300mg / L) is adjusted to 7-8, it is introduced into the first reaction tank, and calcium carbide slag is added to the first reaction tank, and the dosage of calcium carbide slag is 50g / L, after stirring and mixing the fluorine-containing wastewater for 0.5h, the concentration of fluoride ions in the supernatant of the first reaction tank was measured;

[0042](2) after the pH value of the supernatant liquid obtained in step (1) is adjusted to 6.8, it is introduced into the second reaction tank, and an aluminum source defluorination agent is added to the second reaction tank, and the dosage of the aluminum source defluorination agent is 1.75g / L, after stirring and mixing the fluorine-containing wastewater for 0.5h, the concentrat...

Embodiment 3

[0046] The deep defluorination process of a kind of fluorine-containing wastewater proposed in this embodiment includes the following steps:

[0047] (1) after the pH value of fluorine-containing waste water (the concentration of fluoride ion is 9300mg / L) is adjusted to 7-8, it is introduced into the first reaction tank, and calcium carbide slag is added to the first reaction tank, and the dosage of calcium carbide slag is 55g / L, after stirring and mixing the fluorine-containing wastewater for 0.5h, the concentration of fluoride ions in the supernatant of the first reaction tank was measured;

[0048] (2) after the pH value of the supernatant liquid obtained in step (1) is adjusted to 6.8, it is introduced into the second reaction tank, and an aluminum source defluorination agent is added to the second reaction tank, and the dosage of the aluminum source defluorination agent is 1.5g / L, after stirring and mixing the fluorine-containing wastewater for 0.5h, the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com