Blocking remover system and blocking removal method

A plugging removal agent and system technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve the problems of plugging removal agent and plugging removal method that have not been reported publicly, and prevent reservoir secondary The effect of secondary precipitation, prevention of iron ion precipitation, and easy flowback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

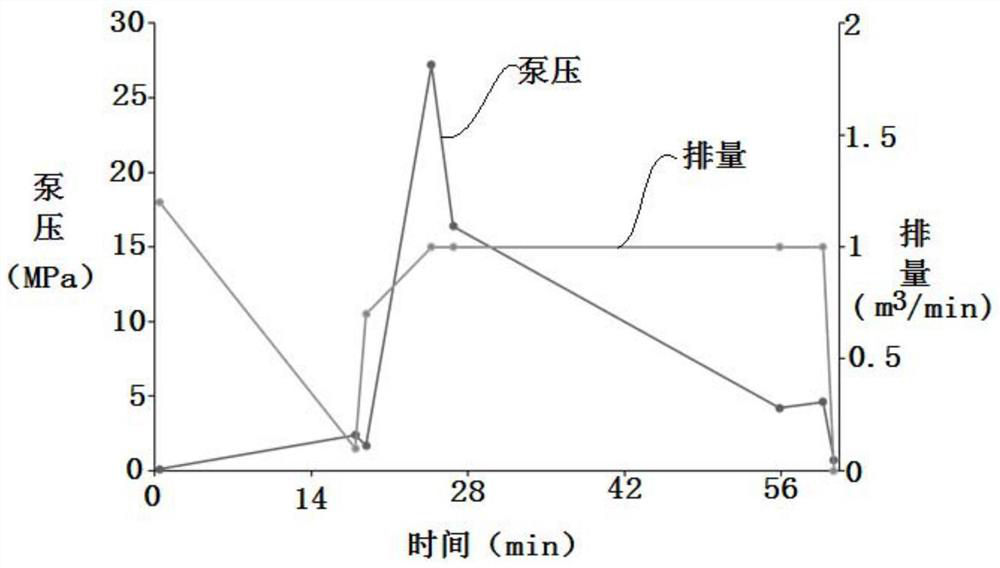

[0087] The present Example 1 provides a plug-removing agent system, and discloses its application in the gas well Se 2-25 in the low-temperature and low-pressure unconsolidated sandstone gas reservoir.

[0088] Well Se 2-25 is a sand control well. The production of this well was stopped on May 20, 2020. After the conventional sand flushing operation with 0.3% xanthan gum was carried out on May 23, the well did not resume. Produce. On May 24, the well carried out the skid-mounted gas lift operation, and the gas lift cycled when it entered the station for production, and no gas and water were produced.

[0089] The plugging removal agent system of the embodiment of the present invention is used to remove the plugging operation of the Se 2-25 well, and the plugging removal agent system used includes a pre-acid and a main acid.

[0090] The pre-acid includes the following components by weight: 8% HCl, 0.6% QNW-A, 1% QHS-M, 1% QTW-C, 2% QJW-O, 0.2% ammonium persulfate , the balan...

Embodiment 2

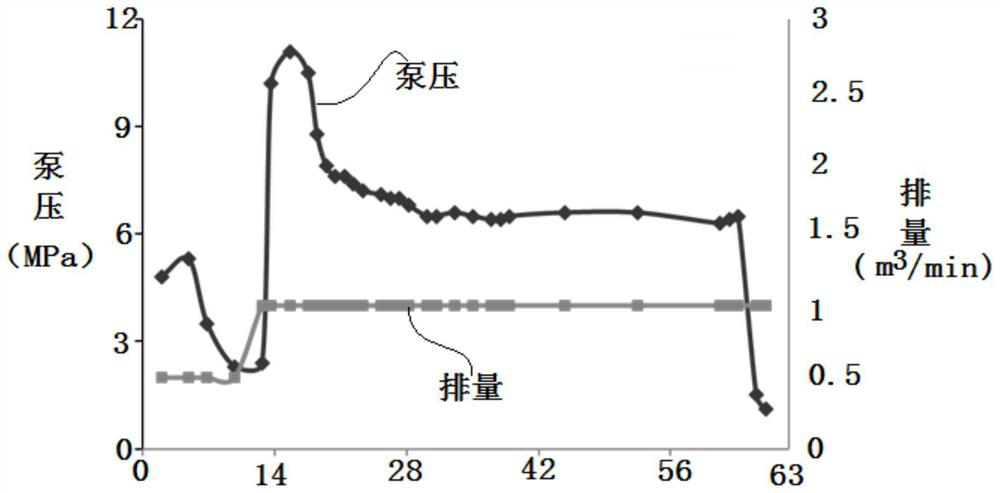

[0097] This Example 2 provides a plugging remover system, and discloses its application in the gas well SeR28-3 in a low-temperature and low-pressure unconsolidated sandstone gas reservoir.

[0098] In May 2020, Well Se R28-3 carried out overhaul and fracturing and sand control operations, and injected 300 cubic meters of fracturing fluid. After that, it was unable to enter the station for production, and the gas lift appeared empty circulation phenomenon. The artificially assisted oil drainage casing pressure was reduced to 0MPa, and no gas and water were discharged, which showed that the reservoir was blocked. Composite plugging due to clay migration.

[0099] The plugging removal agent system provided in Example 2 of the present invention is used for plugging removal, and the plugging removal agent system used includes a pre-acid and a main acid.

[0100] The pre-acid includes the following components by weight: 10% HCL, 0.5% trimethylallyl ammonium chloride, 0.8% ketalami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com