Supercritical carbon dioxide Brayton cycle system control method

A carbon dioxide, circulating system technology, applied in steam engine installations, solar thermal power generation, machines/engines, etc., can solve problems such as high cost, large storage tank size, and many auxiliary equipment, achieving low redundancy and high system reliability. , to achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

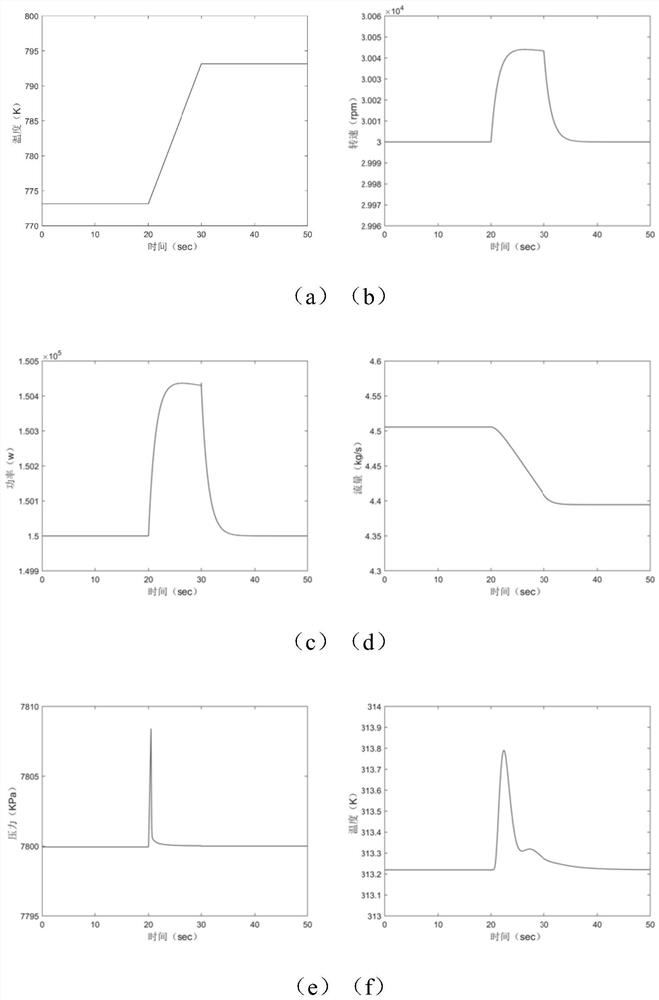

[0074] When the supercritical carbon dioxide circulation system works under the design conditions, the speed is 30000rpm and the output power is 150KW. It is assumed that due to the increase of the heat source power, the turbine inlet temperature rises by 20K within 10s. Under the action of the control strategy proposed by the present invention, the supercritical The changes of parameters in the carbon dioxide cycle system are as follows: image 3 shown.

[0075] When the power of the heat source 2 causes the turbine inlet temperature to rise, the active torque of the system is higher than the reverse torque, resulting in a deviation between the load and the power, the balance of the rotor is destroyed, and the rotational speed tends to increase. Under the action of the module, the valve opening of the first bypass valve 13 is increased, the flow rate of carbon dioxide entering the turbine 3 is reduced, the net output power of the system is reduced, a new rotor balance relatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com