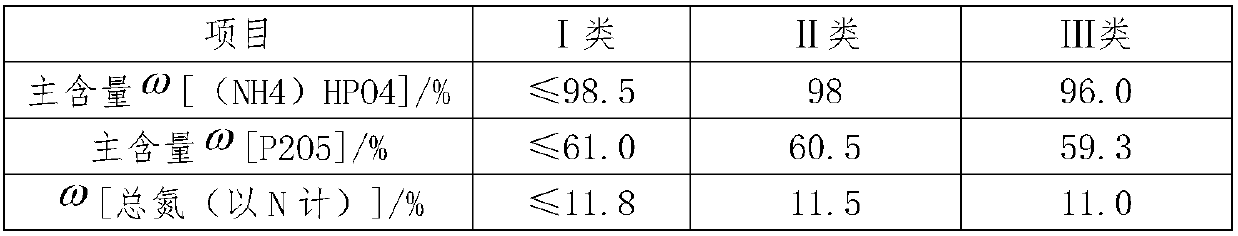

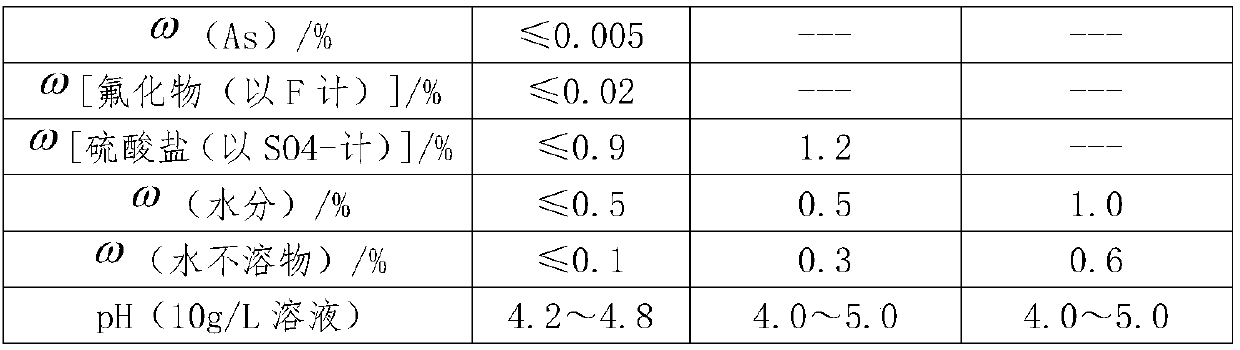

Method for producing industrial-grade ammonium dihydrogen phosphate through microreaction of wet-method phosphoric acid

A technology of first-grade ammonium dihydrogen phosphate and wet-process phosphoric acid, applied in the direction of phosphate and phosphorus-containing oxoacid, can solve the problem of complex purification equipment of wet-process phosphoric acid purification method, high production cost of thermal-process phosphoric acid process, and restriction of comprehensive promotion and application. and other problems, to achieve the effect of improving efficient utilization, small footprint and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

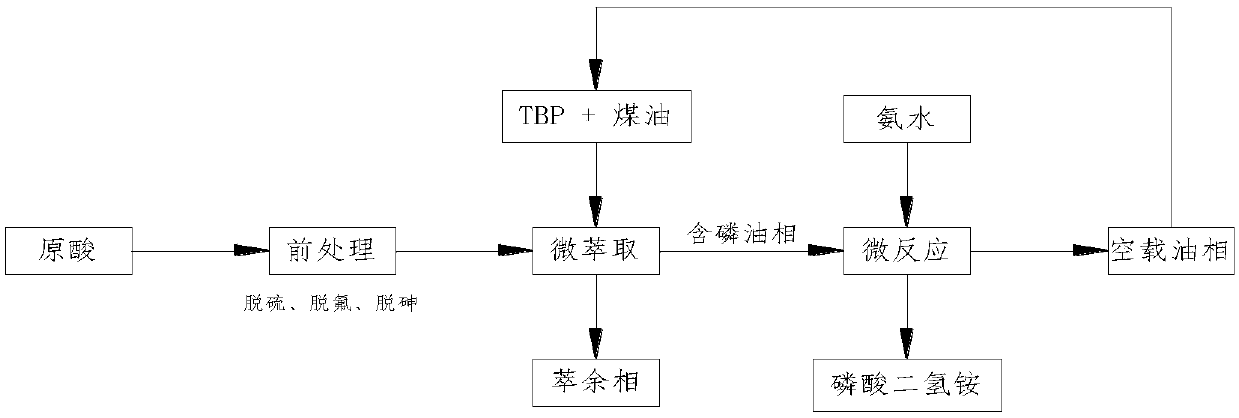

[0027] A method for producing technical-grade ammonium dihydrogen phosphate by micro-reaction of wet-process phosphoric acid, comprising the following steps:

[0028] (1) Phosphoric acid micro-extraction: After desulfurization, defluorination, and arsenic treatment of phosphoric acid, after filtering impurities, the content of P2O5 (ω / %) is 40%, the sulfate (ω / %) is 1.2%, and the content of arsenic ( ω / %) is the pretreatment phosphoric acid of 0.8%, after concentration is 20% tributyl phosphate and kerosene mixing, then with pretreatment phosphoric acid, pumps in the microreactor with the flow rate of 30ml / min by metering pump respectively, Perform micro-extraction at 20°C to obtain a phosphorus-containing oil phase with a ratio (O / W) of 1:1;

[0029] (2) Preparation of potassium dihydrogen phosphate: the phosphorus-containing oil phase in step (1) and 20% ammonia water are pumped into the microreactor respectively to obtain ammonium dihydrogen phosphate and an empty oil phase...

Embodiment 2

[0031] A method for producing technical-grade ammonium dihydrogen phosphate by micro-reaction of wet-process phosphoric acid, comprising the following steps:

[0032] (1) Phosphoric acid micro-extraction: After desulfurization, defluorination, and arsenic treatment of phosphoric acid, after filtering impurities, the P2O5 content (ω / %) was 40%, the sulfate (ω / %) was 1.1%, and the arsenic content ( ω / %) is the pretreatment phosphoric acid of 0.75%, after concentration is 50% tributyl phosphate and kerosene mixing, then with pretreatment phosphoric acid, pumps in the microreactor with the flow velocity of 100ml / min respectively by metering pump, Perform micro-extraction at 70°C to obtain a phosphorus-containing oil phase with a ratio (O / W) of 1:5;

[0033] (2) Preparation of potassium dihydrogen phosphate: the phosphorus-containing oil phase in step (1) and 30% ammonia water are pumped into the microreactor respectively to obtain ammonium dihydrogen phosphate and an empty oil pha...

Embodiment 3

[0035] A method for producing technical-grade ammonium dihydrogen phosphate by micro-reaction of wet-process phosphoric acid, comprising the following steps:

[0036] (1) Phosphoric acid micro-extraction: after desulfurization, defluorination, and arsenic treatment of phosphoric acid, after filtering impurities, the P2O5 content (ω / %) is 40%, the sulfate (ω / %) is 1%, and the arsenic content ( ω / %) is the pretreatment phosphoric acid of 0.7%, after concentration is 30% tributyl phosphate and kerosene mixing, then with pretreatment phosphoric acid, pumps in the microreactor with the flow rate of 60ml / min by metering pump respectively, Perform micro-extraction at 20-70°C to obtain a phosphorus-containing oil phase with a ratio (O / W) of 1:2;

[0037] (2) Preparation of potassium dihydrogen phosphate: the phosphorus-containing oil phase in step (1) and 25% ammonia water are pumped into the microreactor respectively to obtain ammonium dihydrogen phosphate and an empty oil phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com