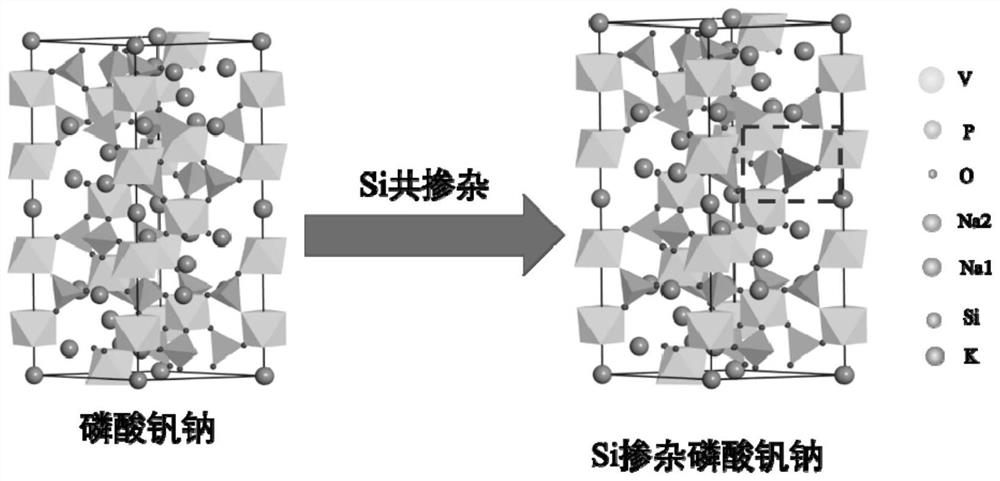

Graphene composite silicon doped sodium vanadium phosphate composite material and preparation method and application thereof

A graphene composite and composite material technology, applied in the fields of nanomaterials and electrochemistry, can solve the problems of conductivity limiting the application and development of sodium vanadium phosphate, and achieve the effects of excellent cycle performance, excellent rate performance, and excellent long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

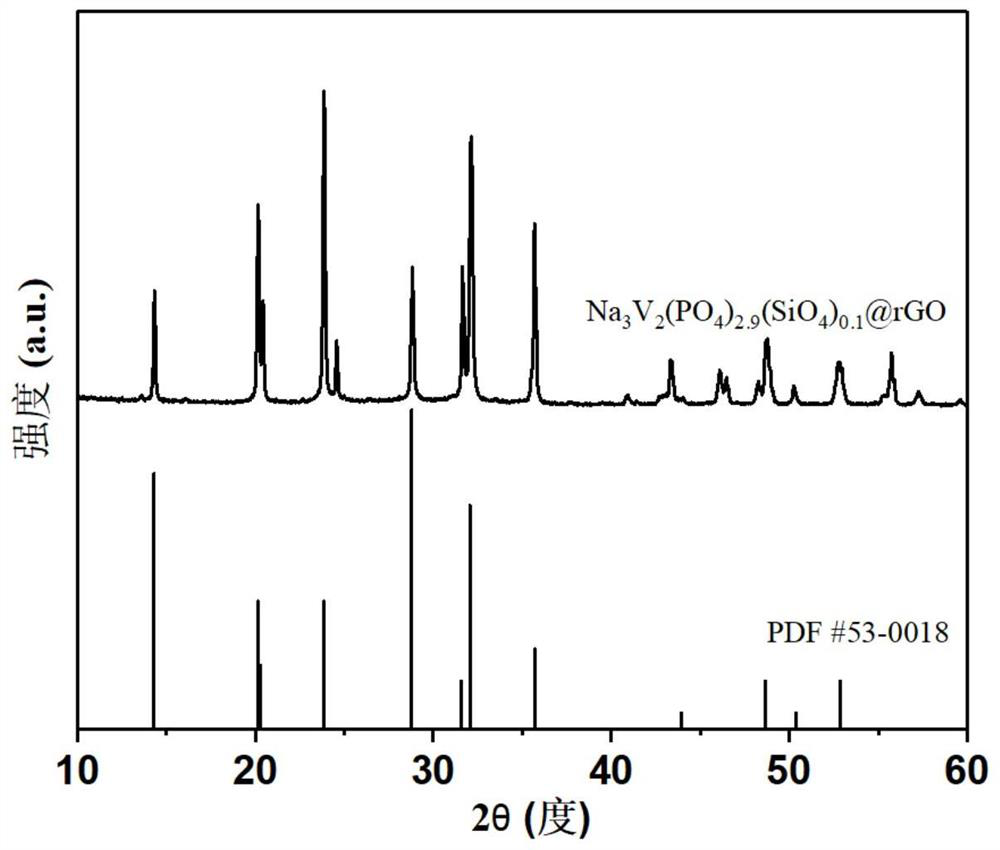

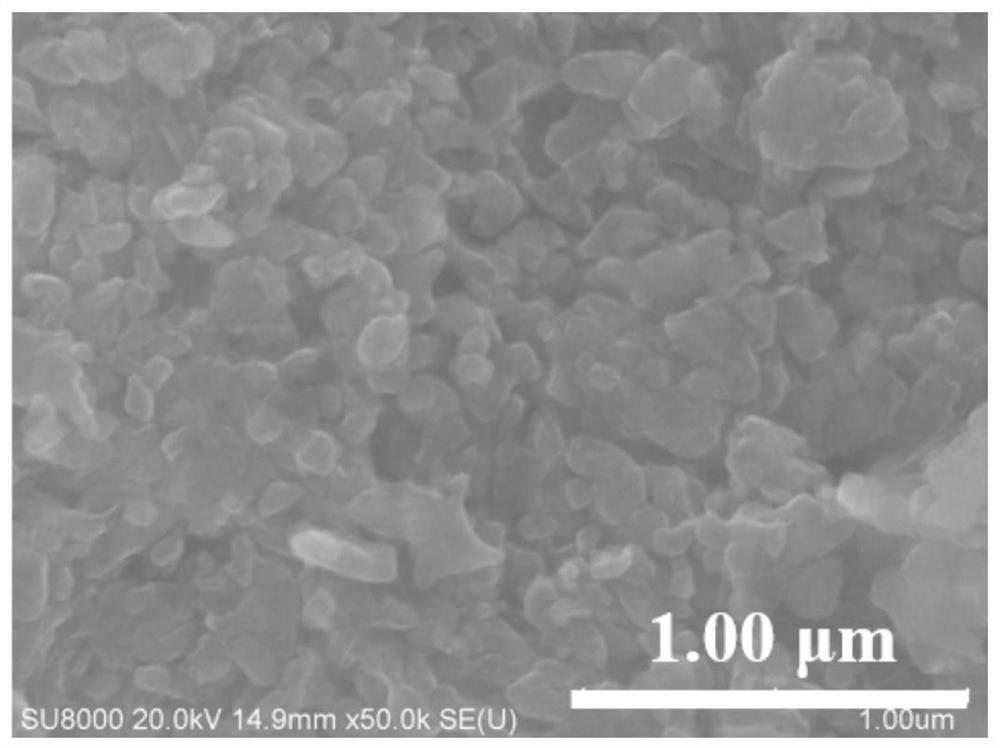

Examples

Embodiment 1

[0041] The preparation method of graphene composite silicon-doped sodium vanadium phosphate composite material, comprising the following steps:

[0042] (1) 4 mmol NH 4 VO 3 Add it to a certain amount of deionized water, and stir it for 15 minutes in a water bath at 70°C to dissolve it;

[0043] (2) 6 mmol C 2 H 2 O 4 Add it to the solution obtained in step (1), and stir it for 15 min under water bath conditions to dissolve it;

[0044] (3) 2.8 mmol Na 2 CO 3 Add it to the solution obtained in step (2), and stir it for 15 min under water bath conditions to dissolve it;

[0045] (4) 0.2 mmol Na 2 SiO 3Add it to the solution obtained in step (3), and stir it for 15 min under water bath conditions to dissolve it;

[0046] (5) 5.8 mmol NH 4 H 2 PO 4 Add it to the solution obtained in step (4), and stir it for 15 min under water bath conditions to dissolve it;

[0047] (6) pouring the solution obtained in step (5) into a polytetrafluoroethylene liner, and hydrothermal...

Embodiment 2

[0056] The preparation method of graphene composite silicon-doped sodium vanadium phosphate composite material comprises the following steps:

[0057] (1) 4 mmol V 2 O 5 Add it to a certain amount of deionized water, and stir it for 15 minutes in a water bath at 70 °C to dissolve it;

[0058] (2) 6 mmol C 2 H 2 O 4 Add it to the solution obtained in step (1), and stir it for 15 min under water bath conditions to dissolve it;

[0059] (3) 2.98mmol Na 2 CO 3 Add it to the solution obtained in step (2), and stir it for 15 min under water bath conditions to dissolve it;

[0060] (4) 0.02mmol Na 2 SiO 3 Add it to the solution obtained in step (3), and stir it for 15 min under water bath conditions to dissolve it;

[0061] (5) 5.98mmol NH 4 H 2 PO 4 Add it to the solution obtained in step (4), and stir it for 15 min under water bath conditions to dissolve it;

[0062] (6) pouring the solution obtained in step (5) into a polytetrafluoroethylene liner, and hydrothermally...

Embodiment 3

[0069] The preparation method of graphene composite silicon-doped sodium vanadium phosphate composite material comprises the following steps:

[0070] (1) 4 mmol NH 4 VO 3 Add it to a certain amount of deionized water, and stir it for 15 minutes in a water bath at 70 °C to dissolve it;

[0071] (2) 4mmol C 6 H 8 O 7 Add it to the solution obtained in step (1), and stir it for 15 min under water bath conditions to dissolve it;

[0072] (3) 5.4 mmol NaHCO 3 Add it to the solution obtained in step (2), and stir it for 15 min under water bath conditions to dissolve it;

[0073] (4) 0.3 mmol Na 2 SiO 3 Add it to the solution obtained in step (3), and stir it for 15 min under water bath conditions to dissolve it;

[0074] (5) 5.7mmol NH 4 H 2 PO 4 Add it to the solution obtained in step (4), and stir it for 15 min under water bath conditions to dissolve it;

[0075] (6) Pour the solution obtained in step (5) into a polytetrafluoroethylene liner, and perform a hydrotherm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com