Composite current collector, preparation method, electrode prepared from composite current collector and battery prepared from composite current collector

A current collector and electrode technology, applied in the direction of electrode carrier/current collector, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effects of improving thermal safety performance and acupuncture pass rate, reducing internal resistance, and low overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

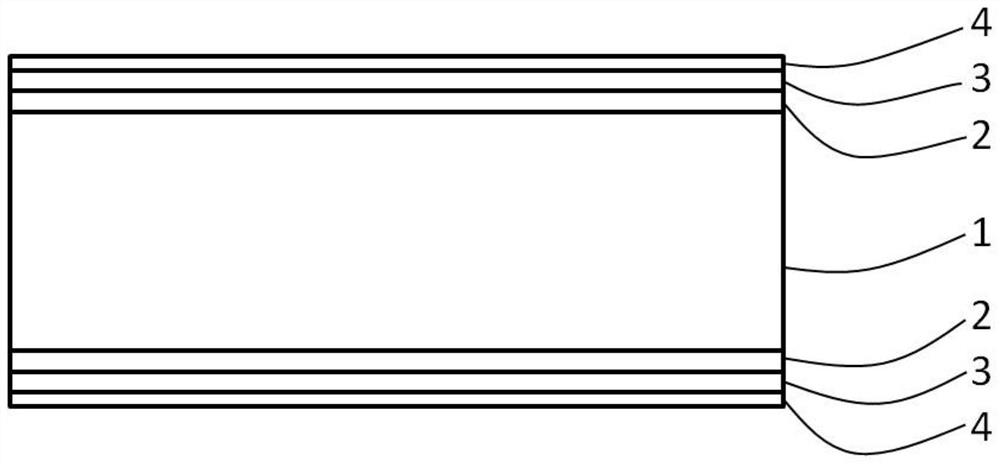

[0043] The application also discloses a preparation method of a composite current collector, comprising the following steps:

[0044] S1, preparing a first conductive metal layer 2 on both sides of the base layer 1;

[0045] S2, preparing a polymer PTC layer 3 on the outside of the first conductive metal layer 2;

[0046] S3 , preparing a second conductive metal layer 4 on the outside of the polymer PTC layer 3 .

[0047] Among them, the first conductive metal layer 2 and the second conductive metal layer 4 are prepared by one or more methods of vacuum evaporation coating, vacuum sputtering coating, vacuum electron beam coating, and electroplating; the polymer PTC layer 3 is made by coating or by spraying.

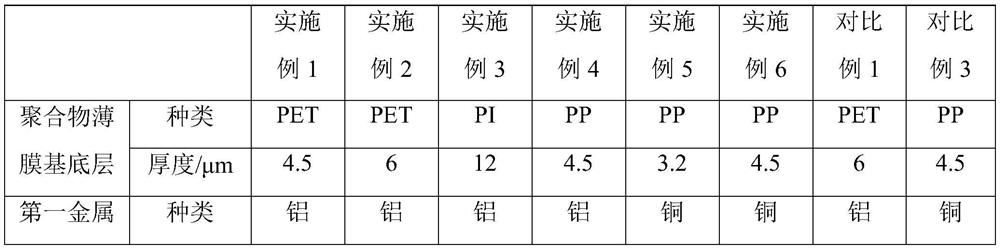

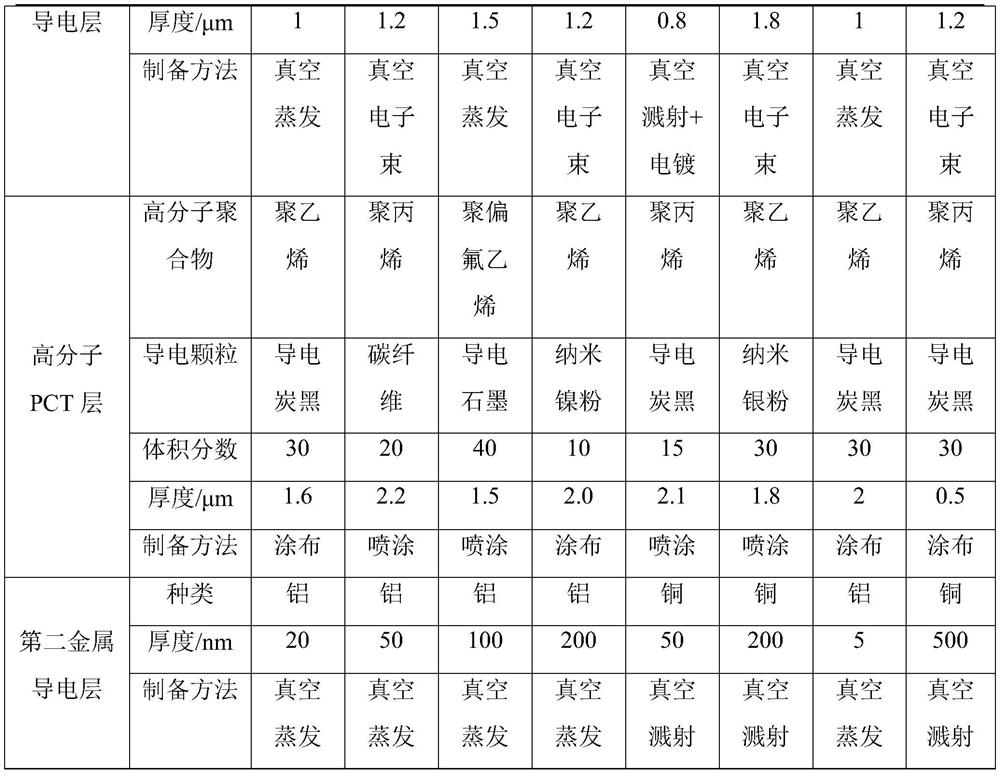

Embodiment 1

[0053] S1. Prepare a first conductive metal layer 2 on both sides of the base layer 1: select a 4.5 μm thick PET (polyethylene terephthalate) film as the base layer 1, and use a 4.5 μm thick base layer 1 on both sides of the base layer 1 By means of vacuum evaporation coating, a first metal conductive layer 2 with a thickness of 1 μm is formed, and the material of the first metal conductive layer 2 is aluminum;

[0054] S2. Prepare a polymer PTC layer 3 on the outside of the first conductive metal layer 2: apply the slurry of polyethylene + conductive carbon black particles on the outside of the first conductive metal layer 2, and dry to obtain a high Molecular PTC layer 3, the volume fraction of the conductive carbon black particles accounts for 30% of the polymer PTC layer 3;

[0055] S3. Prepare a second conductive metal layer 4 on the outside of the polymer PTC layer 3: obtain a second conductive metal layer 4 with a thickness of 20 nm on the outside of the polymer PTC lay...

Embodiment 2

[0057] S1, prepare the first conductive metal layer 2 on both sides of the base layer 1: select a 6 μm thick PET (polyethylene terephthalate) film as the base layer 1, and pass a vacuum on both sides of the 6 μm thick base layer 1 In the method of electron beam coating, a first metal conductive layer 2 with a thickness of 1.2 μm is formed, and the material of the first metal conductive layer 2 is aluminum;

[0058] S2. Prepare a polymer PTC layer 3 on the outside of the first conductive metal layer 2: spray the polypropylene+carbon fiber slurry on the outside of the first conductive metal layer 2, and dry to obtain a polymer PTC layer 3 with a thickness of 2.2 μm , the volume fraction of the carbon fiber accounts for 20% of the polymer PTC layer 3;

[0059] S3. Prepare a second conductive metal layer 4 on the outside of the polymer PTC layer 3: obtain a second conductive metal layer 4 with a thickness of 50 nm on the outside of the polymer PTC layer 3 by vacuum evaporation coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com