Induction electricity taking device of non-closed magnetic core

An inductive power-taking, non-closed technology, which is applied in the direction of circuit devices, battery circuit devices, transformer/inductor cores, etc., can solve problems such as the heating efficiency of the magnetic core, the false contact of the magnetic core, and the influence of the subsequent circuit. Achieve the effect of improving output efficiency, output power and power density, and eliminating coil self-inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Non-closed magnetic core induction power take-off device with linear pullable magnetic core coil assembly

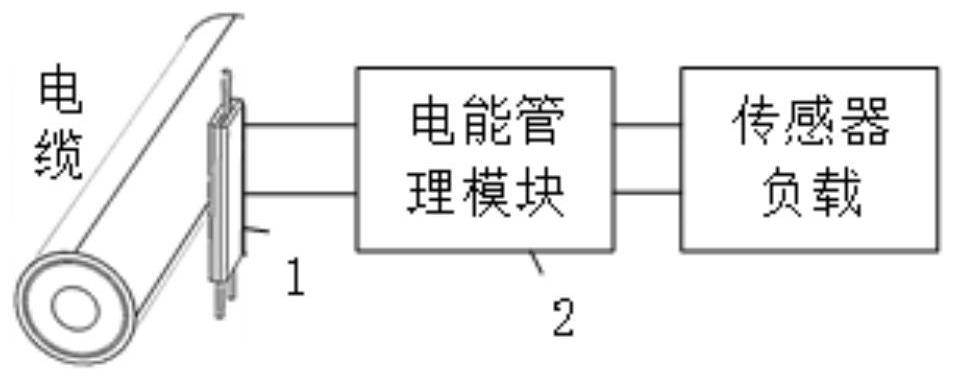

[0026] like figure 1 As shown, the non-closed magnetic core induction power taking device of the present invention includes a linear drawable magnetic core coil assembly 1 and a power management module 2 connected with the linear drawable magnetic core coil assembly 1 . Among them, the linear movable magnetic core coil assembly 1 is clamped to the surface of the cable to be collected, and is set to convert the magnetic energy of the cable to be collected into the output signal of the linear movable magnetic core coil assembly 1; the power management module 2 and the sensor load It is used to convert the output signal of the linear twitchable magnetic core coil assembly 1 into a stable power supply voltage, so as to provide the sensor load.

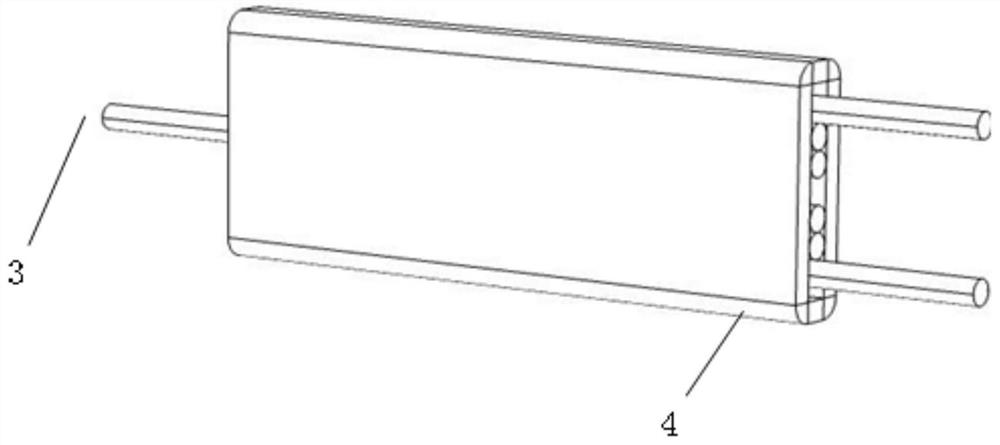

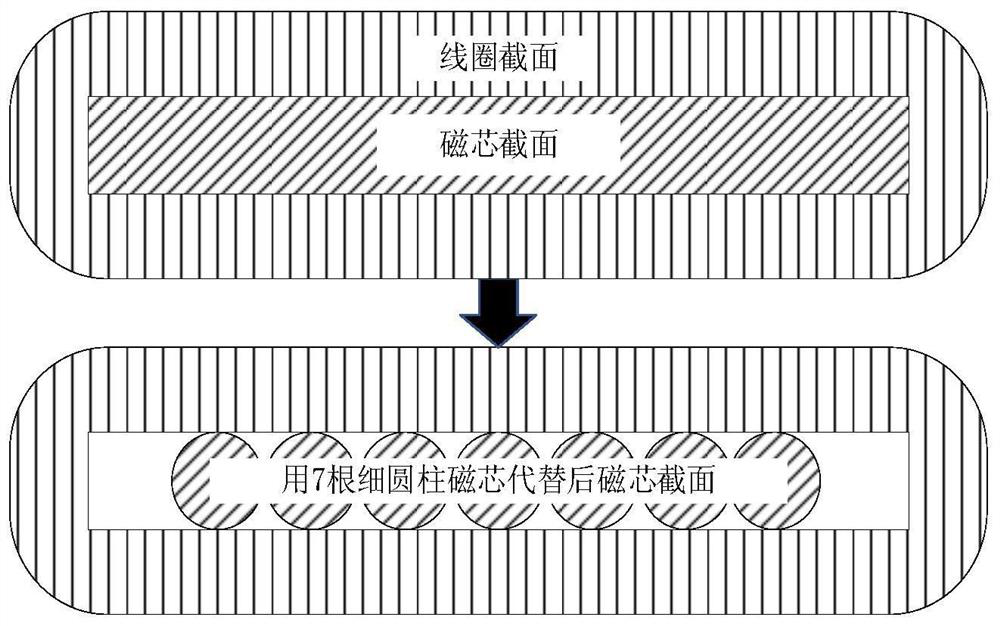

[0027] like figure 2 As shown, the linear drawable magnetic core coil assembly 1 includes a plurality of thi...

Embodiment 2

[0033] Embodiment 2 Non-closed magnetic core induction power take-off device with right-angle twitchable magnetic core coil assembly

[0034] like Figure 4 As shown, the non-closed magnetic core inductive power taking device includes: a right-angle drawable magnetic core coil assembly 5 and a power management module 6 connected to the right-angle drawable magnetic core coil assembly 5 . Among them, the right-angle twitchable magnetic core coil assembly 5 is snap-connected to the surface of the cable to be collected, and is set to convert the magnetic energy of the cable to be collected into the output signal of the right-angle twitchable magnetic core coil assembly 5; the power management module 6 and the sensor load It is connected to convert the output signal of the right-angle twitchable magnetic core coil assembly 5 into a stable power supply voltage, so as to provide the sensor load.

[0035] like Figure 5 As shown, the non-closed right-angle twitch magnetic core coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com