Method for purifying follicle stimulating hormone

A follicle-stimulating hormone and magnesium chloride technology, which is applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of difficulty in control, decreased ability, and changes in the quality of target proteins, and achieves the improvement of yield and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: Purification process

Embodiment 1-1

[0081] Example 1-1: Sequence of purification process

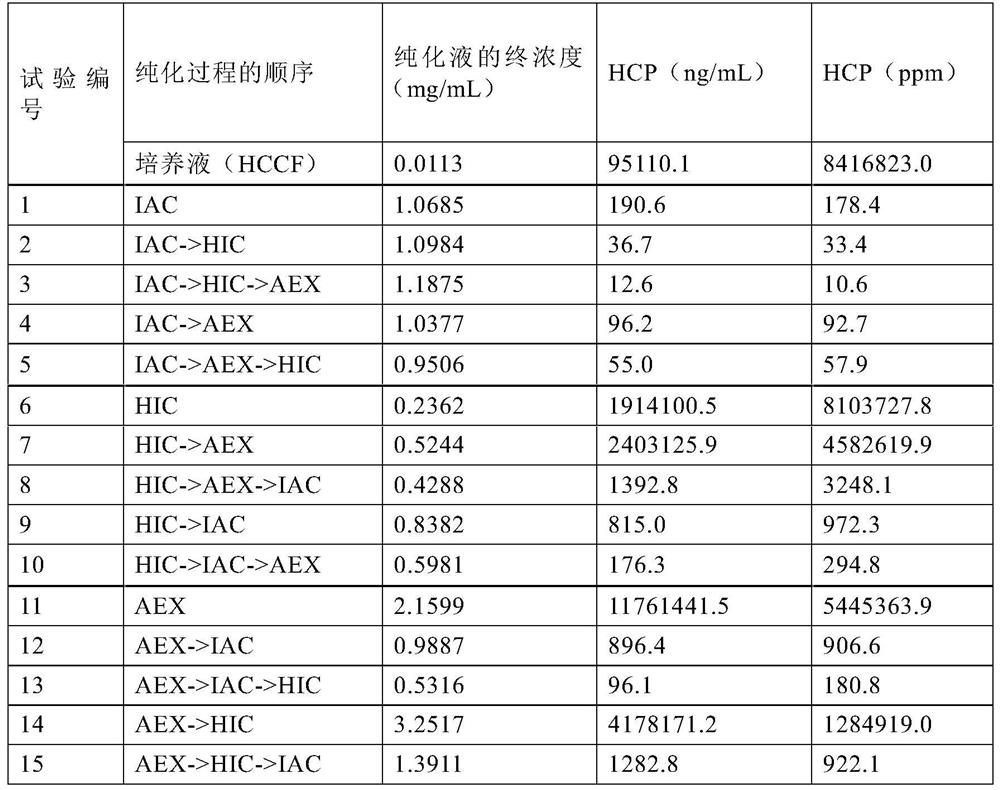

[0082] [Table 1]

[0083] Test number first column second column third column 1 IAC - - 2 IAC HIC - 3 IAC HIC AEX 4 IAC AEX - 5 IAC AEX HIC 6 HIC - - 7 HIC AEX - 8 HIC AEX IAC 9 HIC IAC - 10 HIC IAC AEX 11 AEX - - 12 AEX IAC - 13 AEX IAC HIC 14 AEX HIC - 15 AEX HIC IAC

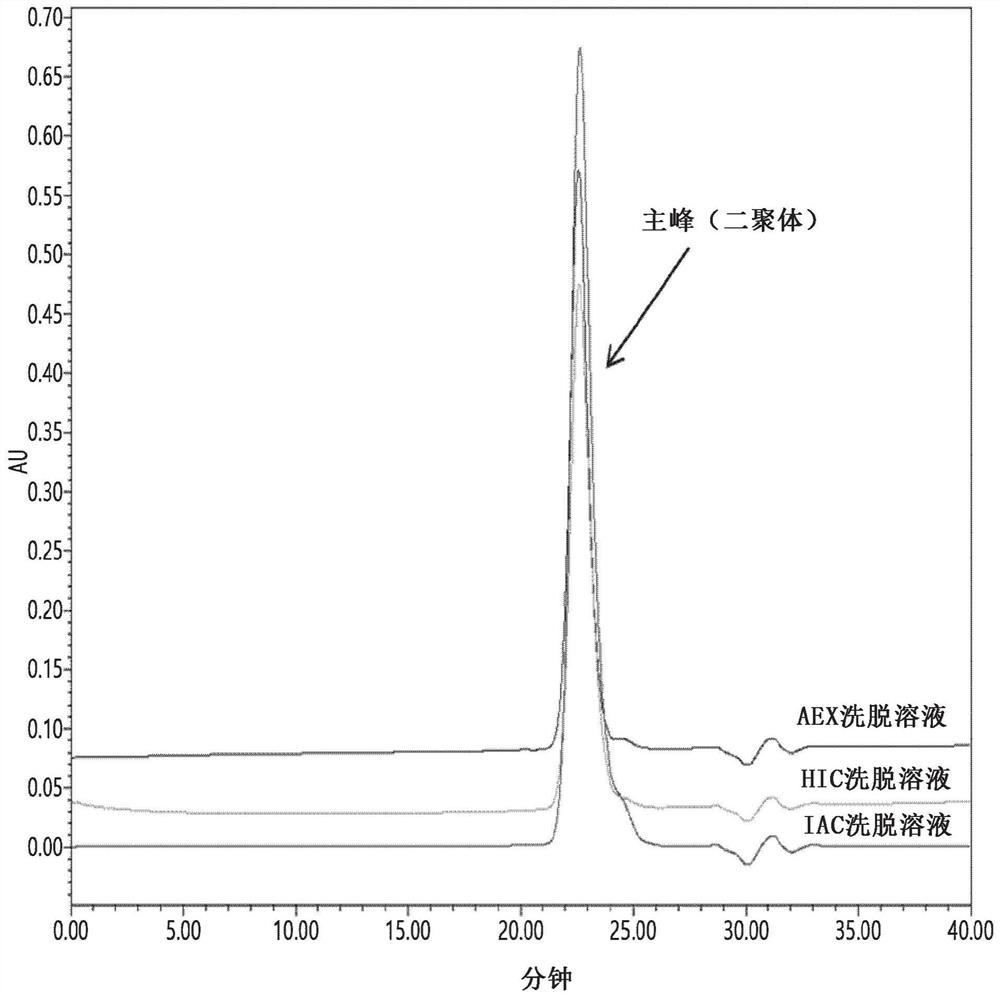

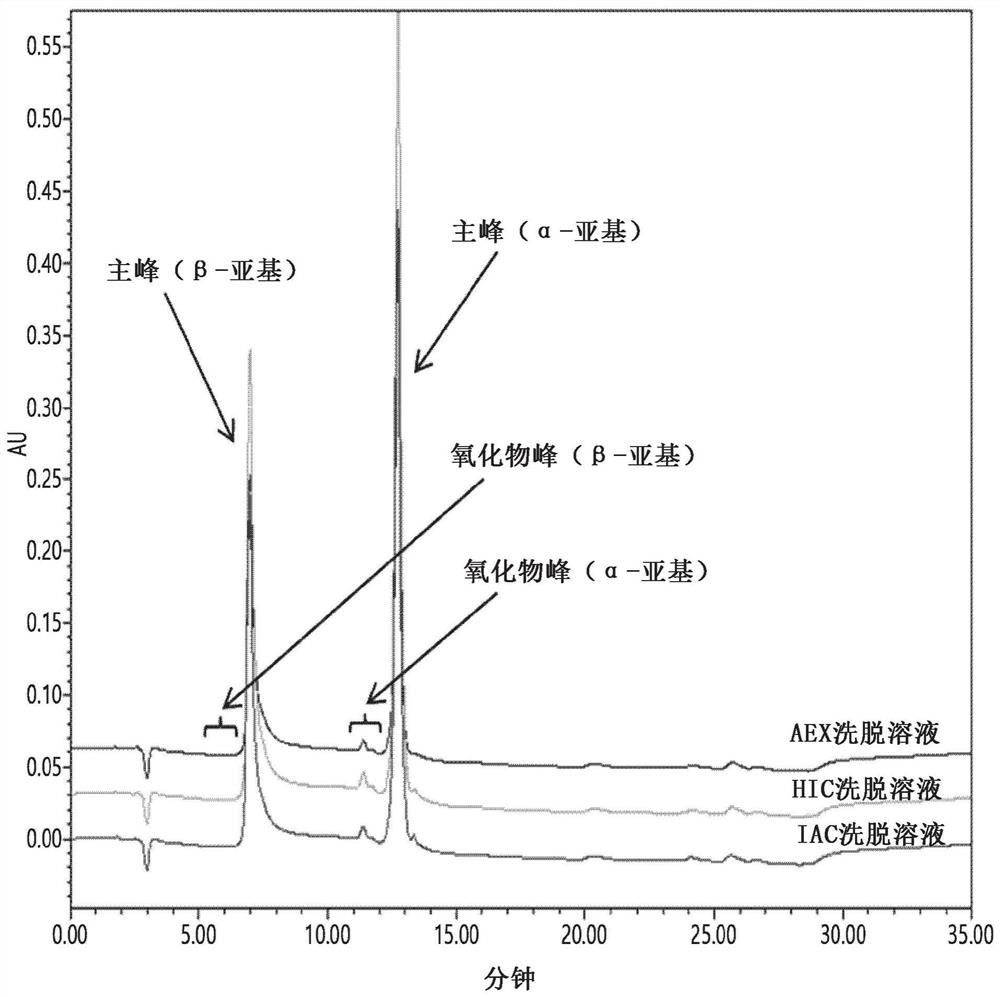

[0084] As described above, in order to optimize the sequence of purification steps and processes for FSH, the FSH protein was purified by 15 different purification methods. Purification proceeds to Step 1, Step 2, or Step 3, depending on the experiment, and the purified solution from each step is collected.

[0085] Since the purified fluid in each step is used as the loading sample for the next step, pretreatment can be performed as needed (eg dilution or buffer exchange for AEX processes, salt addi...

Embodiment 1-2

[0086] Examples 1-2: Purification conditions for each step

[0087] The buffers and specific process conditions used in each purification process are summarized in Tables 2 to 4 below.

[0088] [Table 2] IAC process

[0089] step buffer used Injection volume (CV) balance 20mM Tris (pH 7.6) 7 inject Culture broth or purified solution from the previous step - balance 20mM Tris (pH 7.6) 5 cleaning 1 5mM Tris (pH 7.6) 7 cleaning 2 20mM Tris (pH 7.6) / 1M NaCl 5 cleaning 3 20mM Tris (pH 7.6) / 0.2M MgCl 2

7 elution 20mM Tris (pH 7.6) / 2M MgCl 2

7 CIP 0.5M acetic acid 5

[0090] [Table 3] HIC process

[0091] step buffer used Injection volume (CV) balance 20mM Tris (pH 7.6) / 2M NaCl 5 inject Culture broth or purified solution from the previous step - balance 20mM Tris (pH 7.6) / 2M NaCl 3 elution 20mM Tris (pH 7.6) 10 regeneration WFI 5 CIP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com