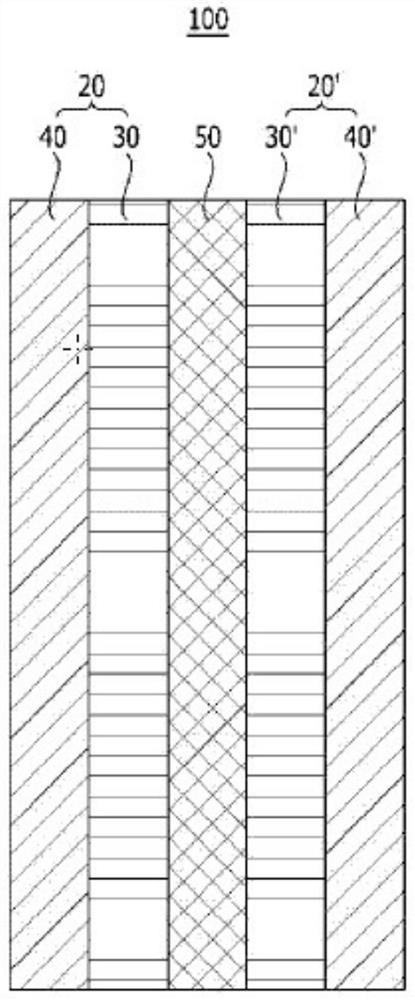

Method for manufacturing polymer electrolyte membrane and electrolyte membrane manufactured thereby

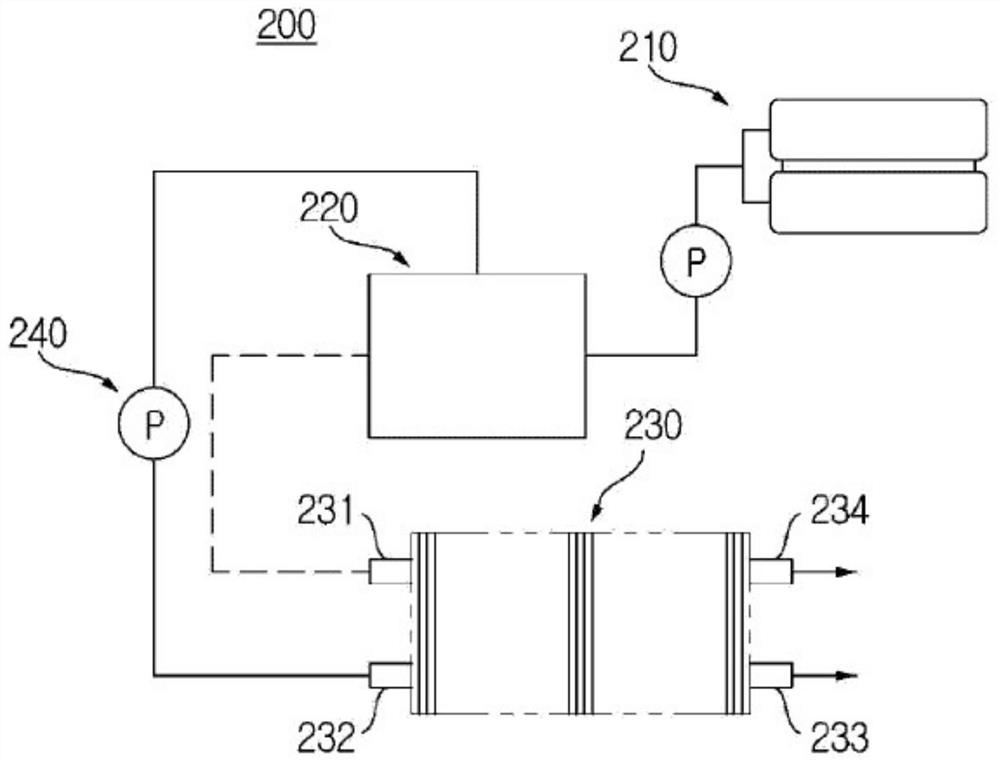

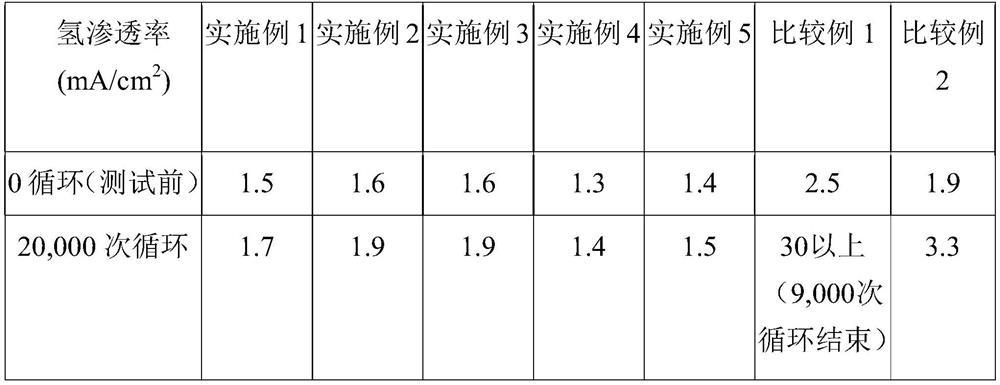

A technology of electrolyte membrane and manufacturing method, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., and can solve problems such as hindering hydrogen ion conduction, fuel cell performance degradation, and reducing hydrogen ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0113] Hereinafter, embodiments of the present invention will be described in detail so that those skilled in the art to which the present invention pertains can easily implement the present invention. However, the present invention may be embodied in various different forms and is not limited to the embodiments described herein.

Embodiment 1

[0116] (1) An expanded polytetrafluoroethylene (e-PTFE) having a thickness of 10 μm and a porosity of 75% was prepared as a porous support.

[0117] (2) The ionomer dispersion Nafion D2021 was put into distilled water as a dispersion medium to prepare an ionomer dispersion liquid containing Nafion in an amount of 1% by weight.

[0118] (3) The e-PTFE support was put into a chamber where the internal temperature was kept at 50° C. and the relative humidity (RH) of the dispersion medium atmosphere was kept at 90% and kept for 10 minutes so that the e-PTFE support was sufficiently wetted by the dispersion medium wet.

[0119] (4) After that, the wetted e-PTFE support was taken out of the chamber and the ionomer dispersion Nafion D2021 was immersed in the e-PTFE support, which was then dried at 80°C for 1 hour and dried at 150°C The heat treatment was performed for 30 minutes to produce a polymer electrolyte membrane with a thickness of 20 μm as a reinforced composite membrane. ...

Embodiment 2

[0121] A polymer electrolyte membrane was produced in the same manner as in Example 1, except that the e-PTFE support was wetted in a chamber whose internal temperature was kept at 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com