Self-adaptive electron beam welding anti-sputtering device

An electron beam welding and anti-sputtering technology, applied in electron beam welding equipment, auxiliary devices, welding equipment, etc., can solve the deviation of clutch hub and sun gear, cannot completely prevent splashing, cannot completely offset stress, etc. problem, to achieve the effect of reducing welding error, moving fast, and reducing spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those of ordinary skill in the art to which the invention pertains can easily implement the embodiments. However, the present invention can also be implemented in various forms, so the present invention is not limited to the embodiments described hereinafter, and in addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings;

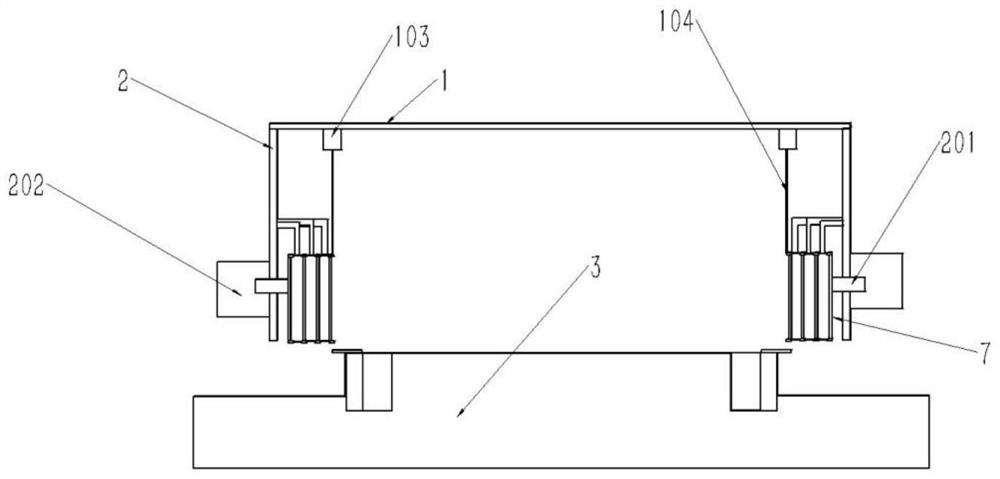

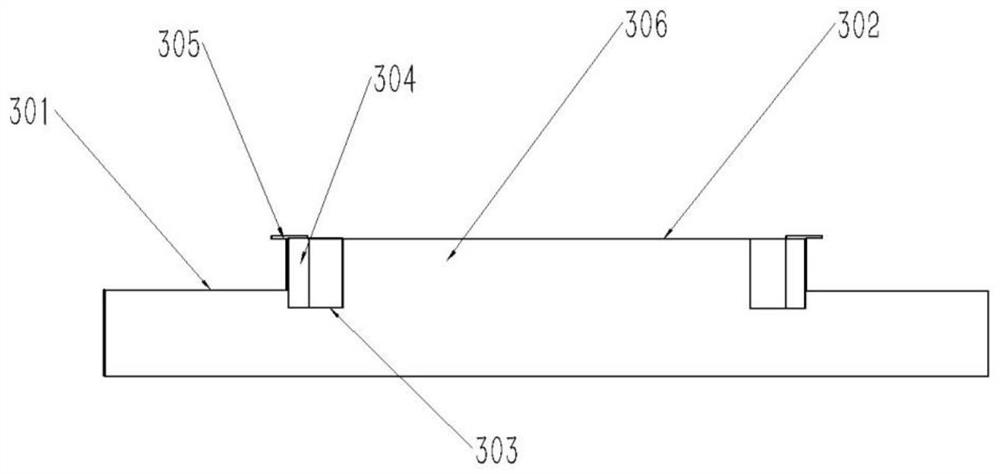

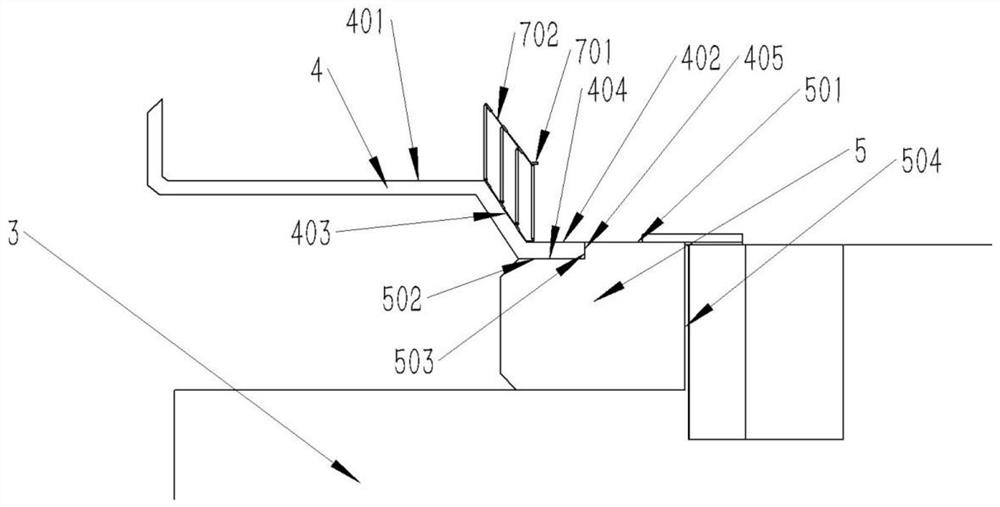

[0027] like Figure 1-5 As shown, an adaptive electron beam welding anti-sputtering device includes: an anti-sputtering baffle 1, a side plate 2, a support table 3, a clutch hub 4, a sun gear 5, a joint portion 6, and an abutting device 7;

[0028] First, the joint part 6 of the sun gear 5 and the clutch hub 4 that needs to be welded is explained:

[0029] like image 3 As shown, the sun gear 5 is a sun gear 5 of a planetary gear mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com