Combined process for treating pyrolysis waste gas

A combined process and pyrolysis technology, used in gas dust removal, petroleum industry, combustible gas purification, etc., to achieve the effect of low one-time investment and operation cost, reducing environmental hidden dangers, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

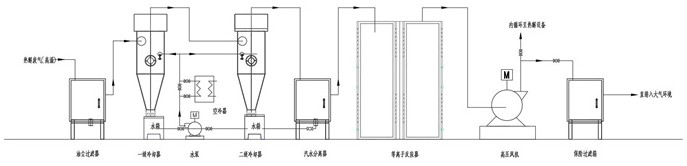

[0025] like figure 1 The embodiment of the present invention provides a combination process for handling heat -solving exhaust gas, including the following steps:

[0026] S1. Thermal dissolving gas first enters the dust filter, filtering most of the dust and caramel, and the filtering material uses multi -layer porous fiber cotton and other materials to replace it regularly;

[0027] S2. After the preliminary filtering gas is sent to the cooling system, the cooler uses the principle of washing and cooling, an external air -cooler, and the cooling gas is used to cool the heat. There is a filler layer inside the cooler. Materials (such as Lasi Ring, Balt Ring, etc.), increase the contact area of gas and cooling water, and improve the cooling efficiency. The two -stage coolers are connected in series. The remaining dust and tar are removed simultaneously, used to use water circulation for washing, and regularly discharged to the sewage receiving system (such as municipal sewage pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com