Hydrofluoric acid wastewater treatment method

A technology for wastewater treatment and hydrofluoric acid, which is applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc. It can solve the problems of reducing fluoride ion concentration, undisclosed, etc., and achieve cost reduction and environmental protection effects. The effect of reducing the harmfulness of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

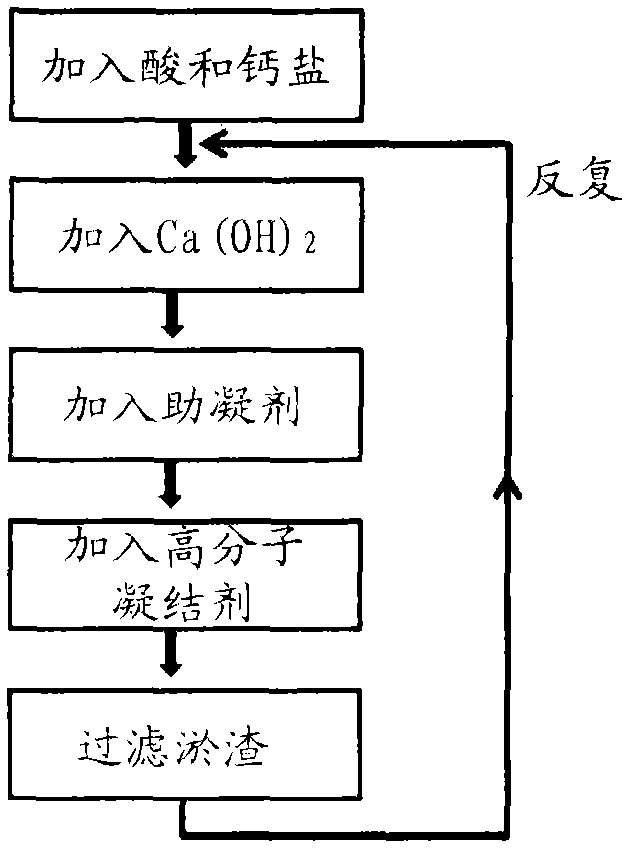

[0018] figure 1 It is a flowchart showing the overall flow of the embodiment of the present invention.

[0019] The purpose of the present invention is to remove high-concentration fluorine ions remaining in etching wastewater generated after performing fine grinding process, pattern forming process and other processes on glass substrates. The main process is to use fluoride ion (F - ) precipitation reaction to form sludge, which was removed by filtration.

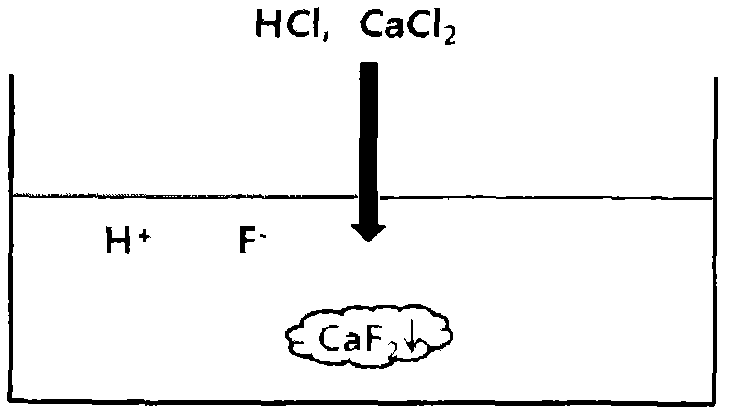

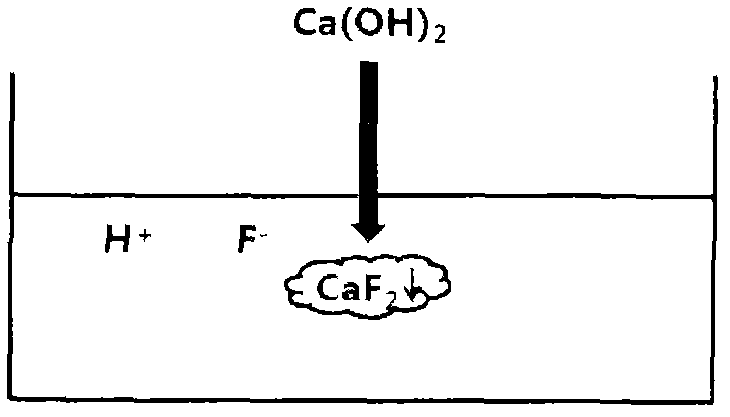

[0020] After the etching process, a large amount of hydrofluoric acid will remain in the solution, so the fluoride ion concentration will reach the level of 25,000ppm. In this wastewater, calcium-containing salts are first added together with a strong acid and stirred. During this process, calcium ions (Ca +2 ) combines with fluoride ions to form calcium fluoride (CaF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com