Environment-friendly water-based synthetic leather and production process thereof

A synthetic leather and environmentally friendly technology, applied in the field of synthetic leather, can solve problems such as hazards, achieve the effect of solving chemical pollution and high environmental protection of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

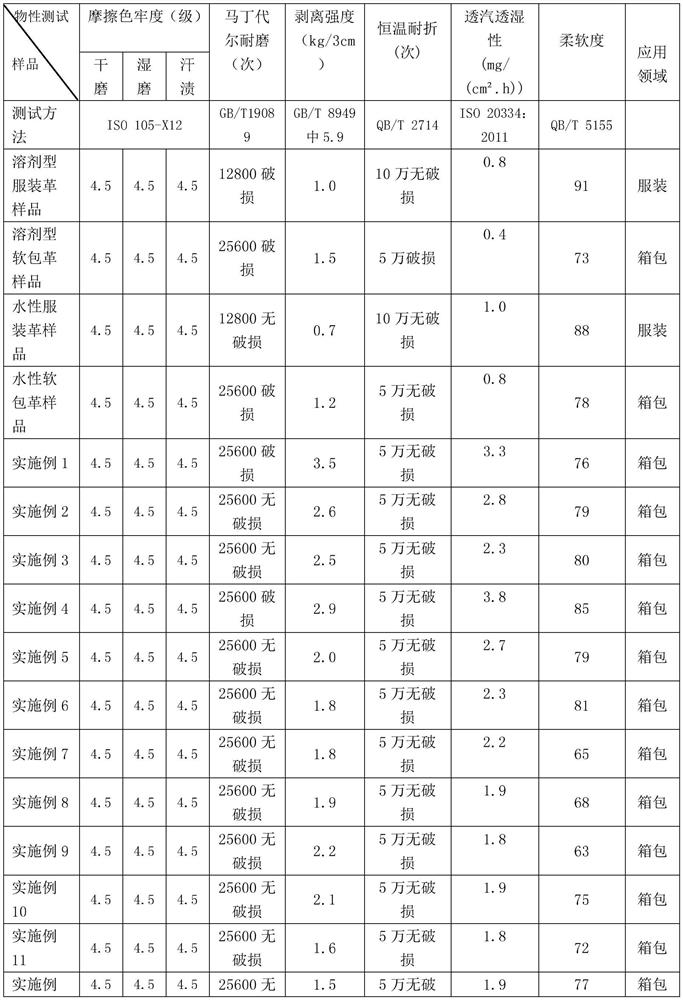

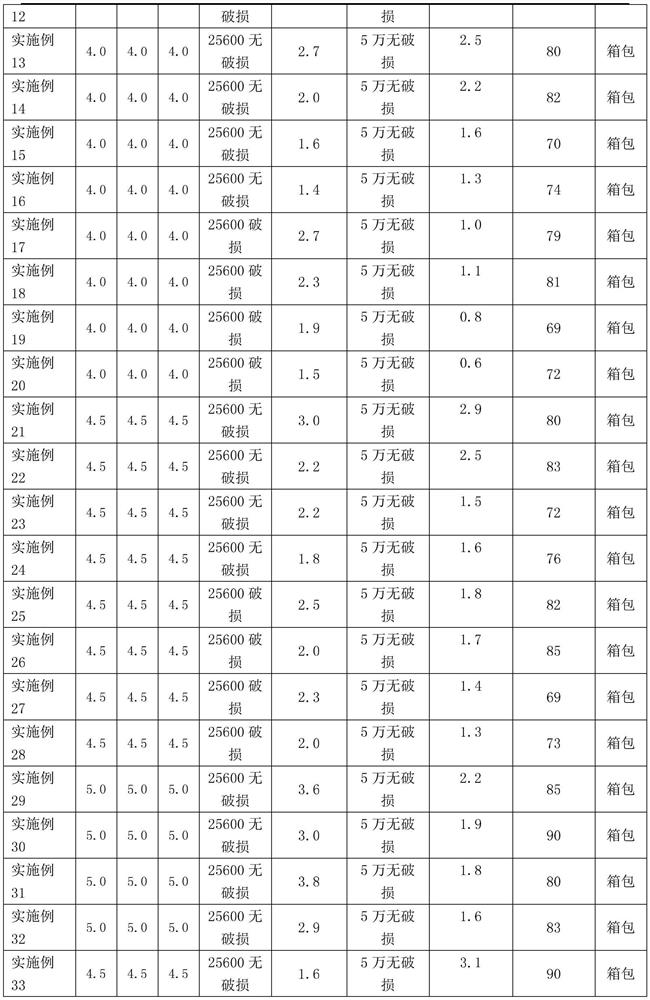

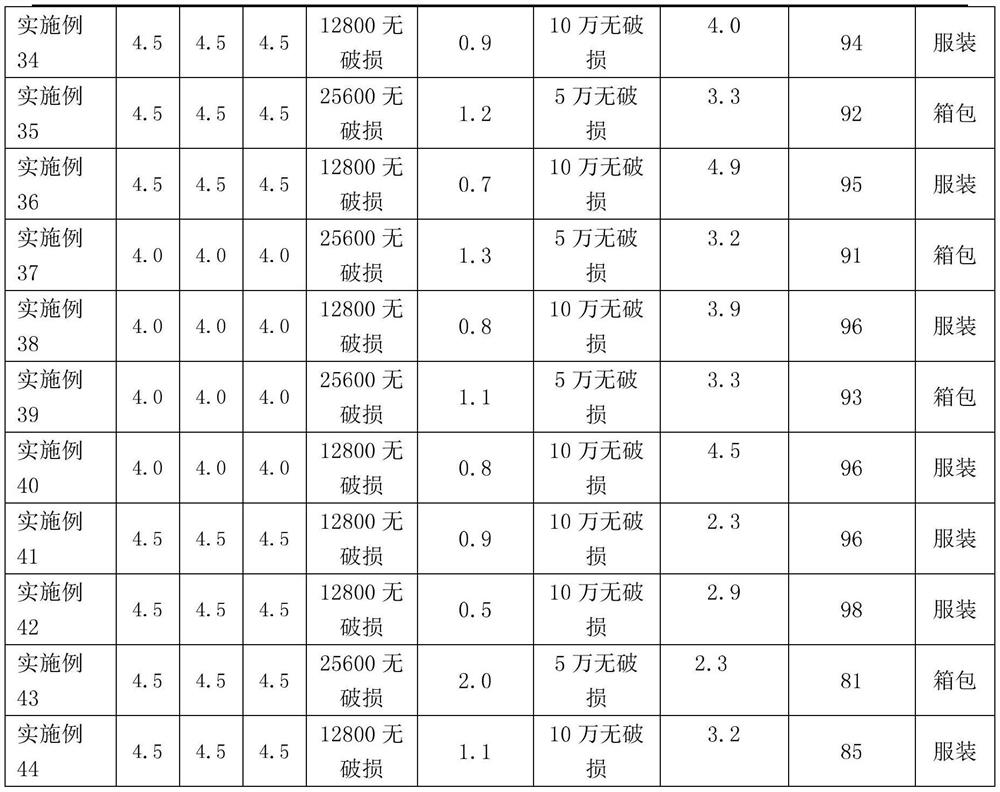

Examples

Embodiment 1

[0049] Embodiment 1: An environmentally friendly water-based synthetic leather, comprising a surface layer, an intermediate layer and a base layer in sequence from the outside to the inside; the intermediate layer is a one-layer adhesive layer; the base layer is a base cloth, and the surface layer is It is formed by coating the water-based slag surface layer slurry; the adhesive layer is formed by coating the water-based slag adhesive layer slurry; the configuration of the water-based slag surface layer slurry includes the following components: anionic aliphatic water-based polyurethane 50 parts of emulsion, 0.5 parts of silicone defoamer, 1.5 parts of silicone wetting agent, 2.1 parts of emulsifier, 30 parts of coffee grounds, 1.6 parts of isothiazolinone fungicide, 1.2 parts of sodium o-phenylphenol mildew inhibitor, 2 parts of aziridine crosslinking agent, 2.5 parts of cellulose thickener; the configuration of the water-based residue adhesive layer slurry includes the follow...

Embodiment 2

[0055] Embodiment 2: an environmentally friendly water-based synthetic leather, comprising a surface layer, an intermediate layer and a base layer in sequence from the outside to the inside; the intermediate layer is a two-layer foam layer; the base layer is a base cloth, and the surface layer is It is formed by coating the water-based slag surface layer slurry; the foam layer is formed by coating the water-based slag foam layer; the configuration of the water-based slag surface layer slurry includes the following components: anionic aliphatic water-based polyurethane emulsion 50 parts, 0.8 parts of silicone defoamer, 30 parts of coffee grounds, 1.6 parts of isothiazolinone fungicide, 1.2 parts of sodium o-phenylphenol mildew inhibitor, 2 parts of aziridine crosslinking agent, 1.5 parts of silicone wetting agent parts, 2.1 parts of emulsifier, 3.0 parts of cellulose thickener; the configuration of the water-based slag foam layer slurry includes the following components: 50 part...

Embodiment 3

[0061] Embodiment 3: a kind of environment-friendly water-based synthetic leather, including a surface layer, an intermediate layer and a base layer in turn from outside to inside; the intermediate layer is a foam layer and an adhesive layer of one layer; the base layer is Base cloth, the surface layer is formed by coating the water-based slag surface layer slurry; the water-based slag surface layer slurry configuration includes the following components: 40 parts of anionic aliphatic aqueous polyurethane emulsion, 0.8 part of silicone defoamer , 50 parts of coffee grounds, 1.6 parts of isothiazolinone bactericide, 1.2 parts of sodium o-phenylphenol mildew inhibitor, 2 parts of aziridine crosslinking agent, 1.5 parts of silicone wetting agent, emulsifier 3.0, cellulose enhancer 2.5 parts of thickener; the foam layer is formed by coating the water-based slag foam layer; the slurry configuration of the water-based slag foam layer includes the following components: 50 parts of anio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com