Heating method for preparing metal substrate film

A metal substrate and heating method technology, which is applied in metal material coating technology, ion implantation plating, gaseous chemical plating, etc., can solve problems such as uneven heating, and achieve a wide heating range, simple operation, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: A 20 cm long nickel-based tape yttrium barium copper oxide (YBCO) superconducting tape was prepared.

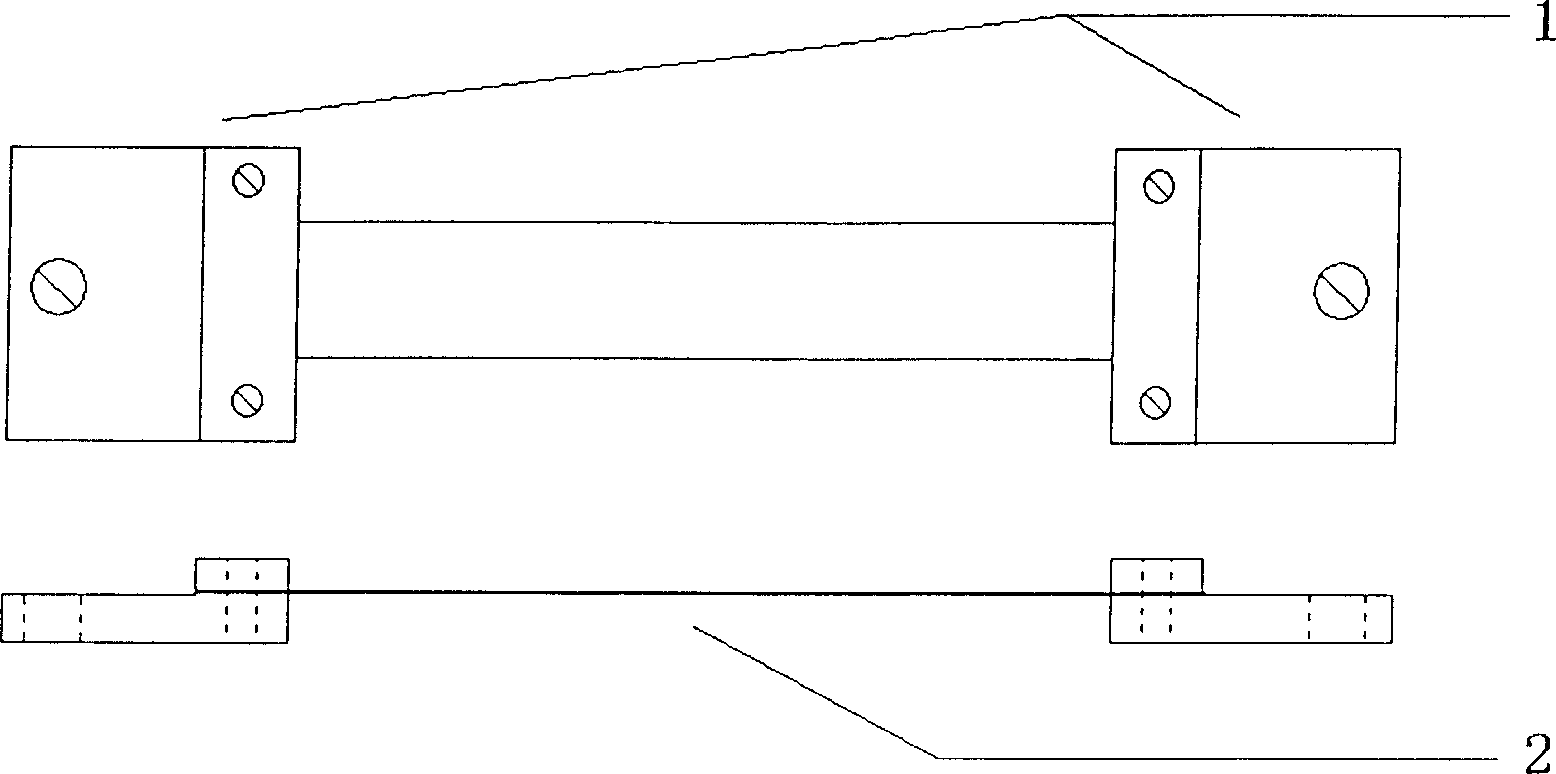

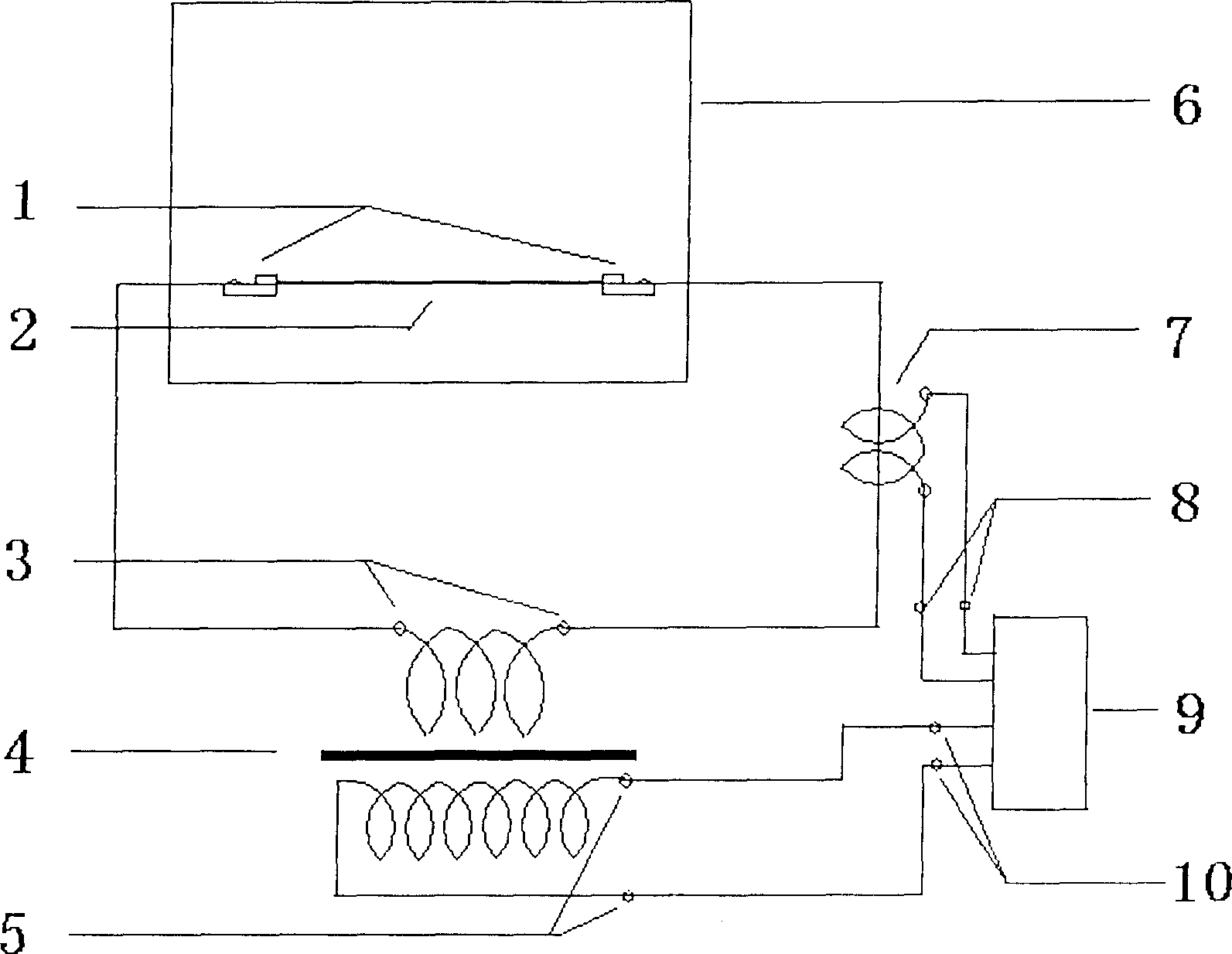

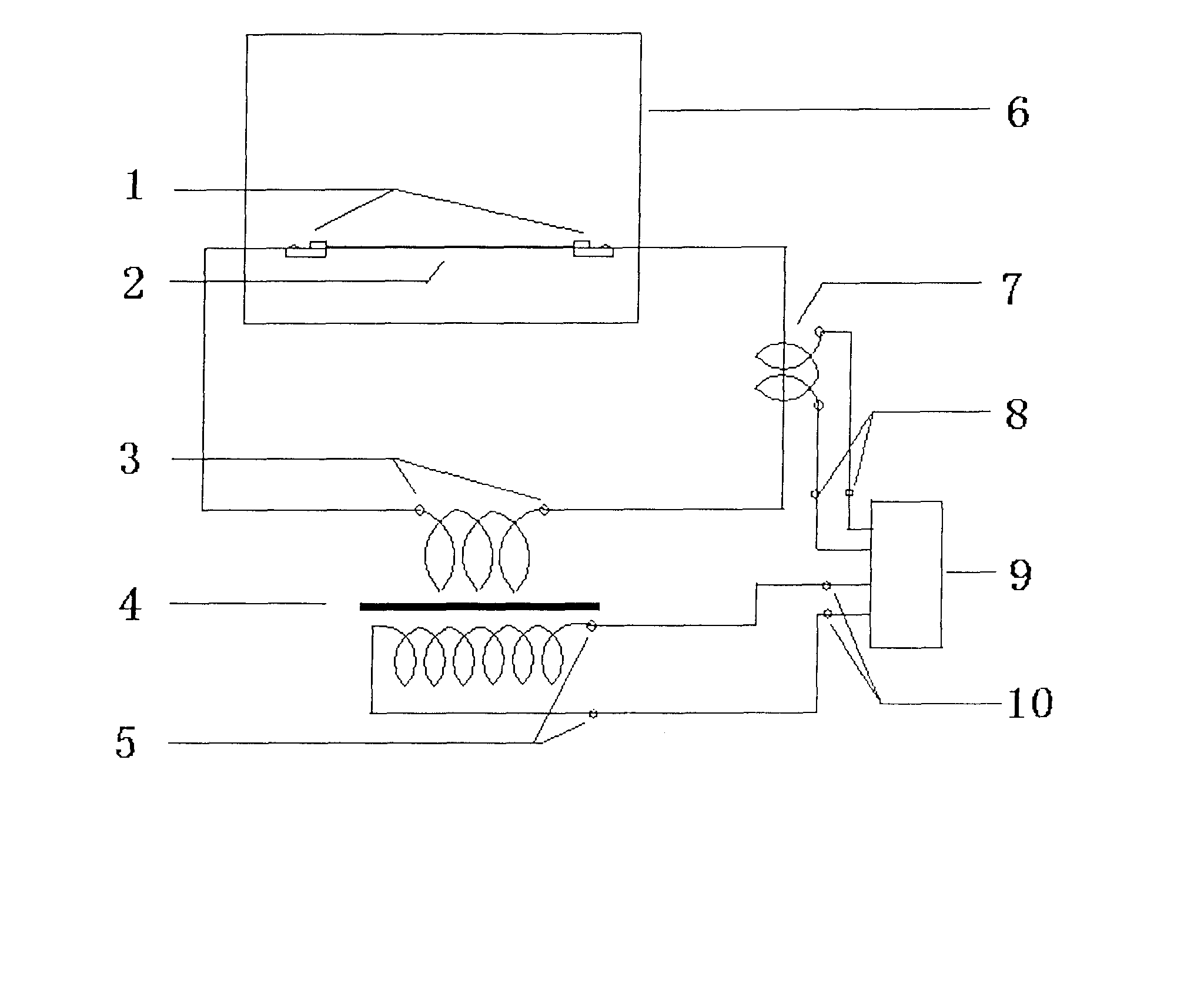

[0015] The invention consists of figure 1 base in and figure 2 The auxiliary circuits in it are composed together. The two ends of a 20 cm long and 1 cm wide double-textured nickel-based tape were wrapped with silver foil and sandwiched between two copper plate electrodes. The copper plate electrodes were fixed on the steel base of the PLD equipment growth chamber through insulating ceramics. according to figure 2 Connect the circuit, evacuate the vacuum chamber to about 20Pa, and then calibrate the temperature controller through the infrared thermometer. By controlling the magnitude of the current to stabilize the temperature of the substrate at 700°C, a layer of 500nm YSZ is grown by laser deposition technology, and then the substrate is heated to 870°C, and YBCO is deposited by laser for 40 minutes to obtain a superconducting layer with a thickness of...

Embodiment 2

[0016] Embodiment 2: grow YBCO superconducting thin film on long silver tape substrate

[0017] The invention consists of figure 1 base in and figure 2 The auxiliary circuits in it are composed together. The two ends of the textured silver-based strip are respectively sandwiched between two copper plate electrodes, and the copper plate electrodes are fixed on the growth chamber base of the PLD device through insulating ceramics. The preparation process is as above, and a high-quality superconducting thin film is obtained.

Embodiment 3

[0018] Example 3: An MgO isolation layer was grown on a nickel-based strip with a length of 20 cm and a width of 5 cm.

[0019] The invention consists of figure 1 base in and figure 2 The auxiliary circuits in it are composed together. Both ends of the nickel-based tape are wrapped with silver foil, which are respectively sandwiched between two copper plate electrodes, and the copper plate electrodes are fixed on the base of the evaporation equipment through insulating ceramics. according to figure 2 Connect the circuit and evacuate the vacuum chamber to 1Pa. Also use the infrared thermometer to calibrate the temperature controller. At room temperature, metal Mg is evaporated for 10 minutes, then oxygenated to 10Pa, the nickel strip is heated to 380°C for 30 minutes, and then heated to 660°C for 20°C oxidation. The surface of the obtained MgO isolation layer is uniform, smooth and dense.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com