Astigmatism eliminating three spherical reflector system

A spherical mirror, astigmatism elimination technology, applied in the field of optical systems, can solve the problems of difficult processing and adjustment, high development cost, difficult mass production, etc. Difficulty reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

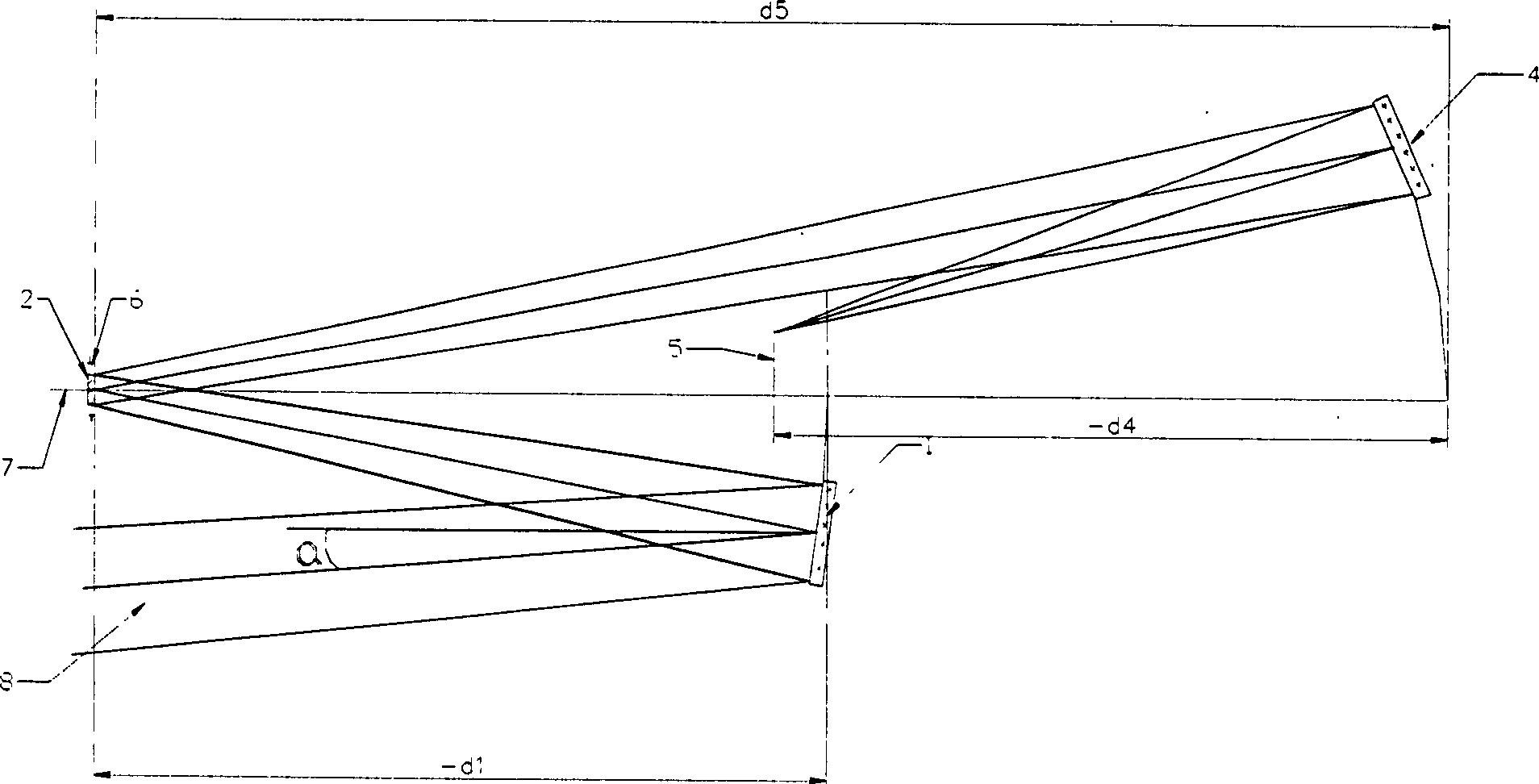

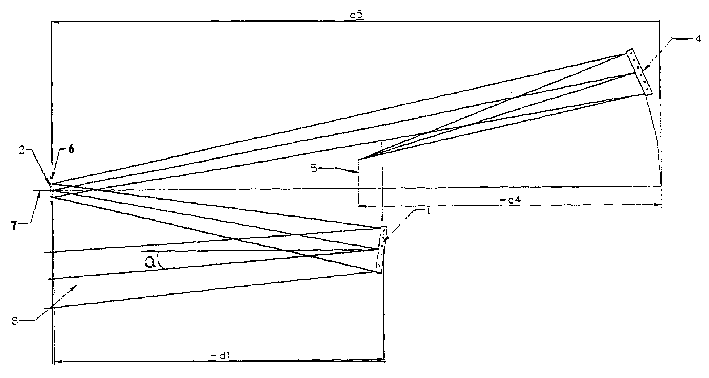

[0027] Embodiment 1 is an aerospace push-broom imaging optical system, and its structure is as follows: figure 1 Shown by:

[0028] Focal length f'=800mm; field of view is 3°×0.5°; relative aperture is 1 / 12;

[0029] Dimensions: (1300×400×150)mm 3 ; Spectral segment: (0.5-0.78) micron;

[0030] System working field of view: X direction is (-1.5° to 1.5°); Y direction is (3.5° to 4.0°).

[0031] Structural parameters of the primary mirror 1: the radius of curvature is -2431.698mm (concave); the distance d1 between the primary and secondary mirrors is -700mm; the Y off-axis distance is -109.437mm; the tilt is 0; the eccentricity coefficient is 0; the clear aperture is (55.29×41.18)mm 2 .

[0032] Structural parameters of secondary mirror 2: radius of curvature is -743.898mm (convex); distance d5 from secondary mirror to third mirror is 1299.759mm; Y off-axis value is 0; tilt value is 0; eccentricity coefficient is 0; clear aperture diameter It is 14.1mm.

[0033] The stru...

Embodiment 2

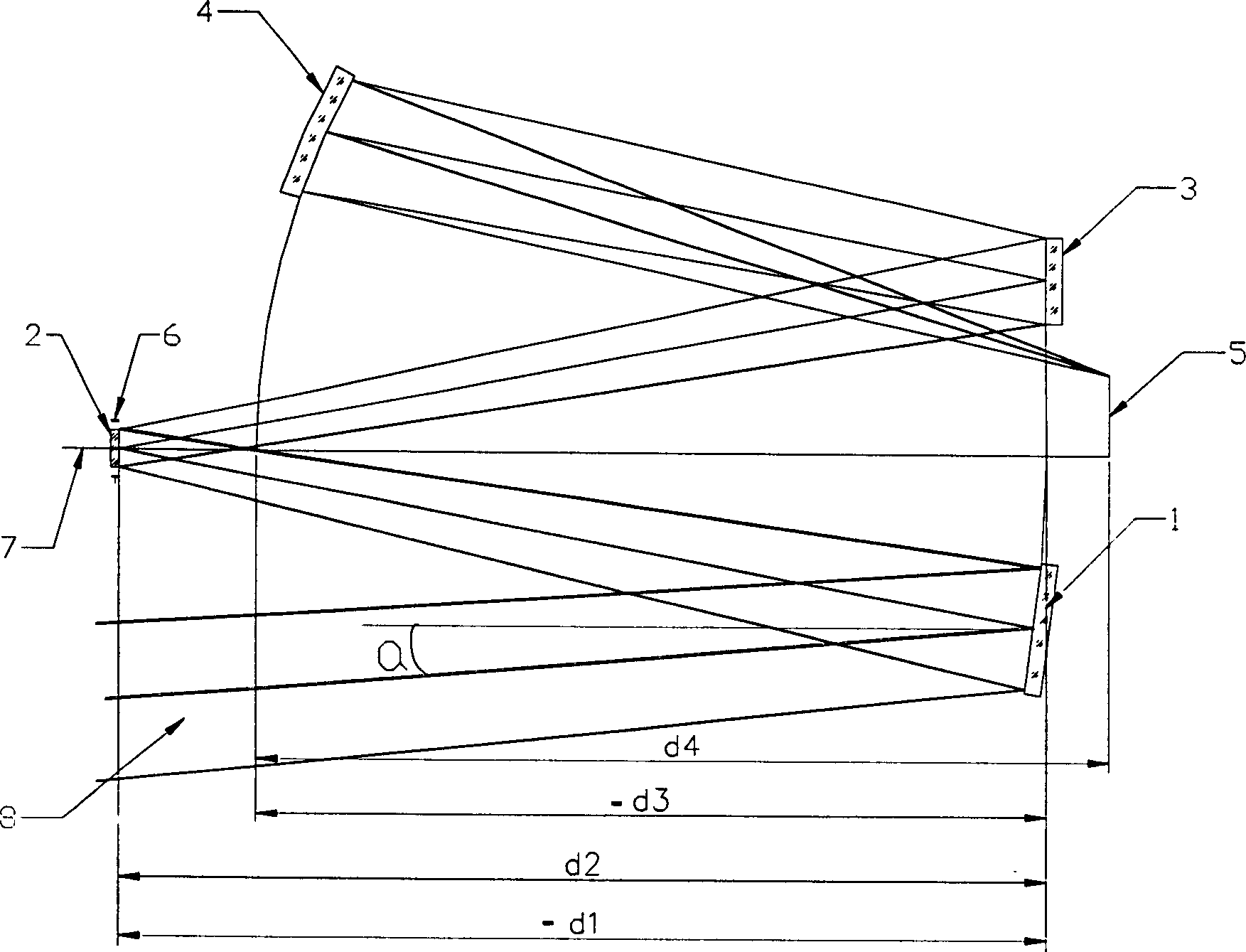

[0037] Embodiment 2 is a push-broom optical system for a microsatellite or a reconnaissance aircraft, and its structure is as follows: figure 2 Shown:

[0038] Focal length f'=500mm; field of view is 6°×0.8°; relative aperture is 1 / 12;

[0039] Dimensions: (482×440×260)mm 3 ; Spectral segment: (0.5-0.78) micron;

[0040] Offset field of view: (-3° to 3°) in the X direction; (4.2° to 5.0°) in the Y direction.

[0041] Structural parameters of primary mirror 1: radius of curvature is -1519.828mm (concave surface); distance d1 between primary mirror 1 and secondary mirror 2 is -437.5mm; Y off-axis is -84.692mm; inclination is 0; eccentricity coefficient is 0 ; Clear aperture is (77×30)mm 2 .

[0042] The structural parameters of the secondary mirror 2: the radius of curvature is -464.944mm (convex); the distance d2 between the secondary mirror 2 and the folding mirror 3 is 437.5mm; the Y off-axis is 0mm; the inclination is 0; the eccentricity coefficient is 0; The light ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com