Compactor for straw quality raw material

A raw material and grass quality technology, applied in the field of compaction, can solve the problems of complicated equipment, complicated operation, long time for water absorption and collapse, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

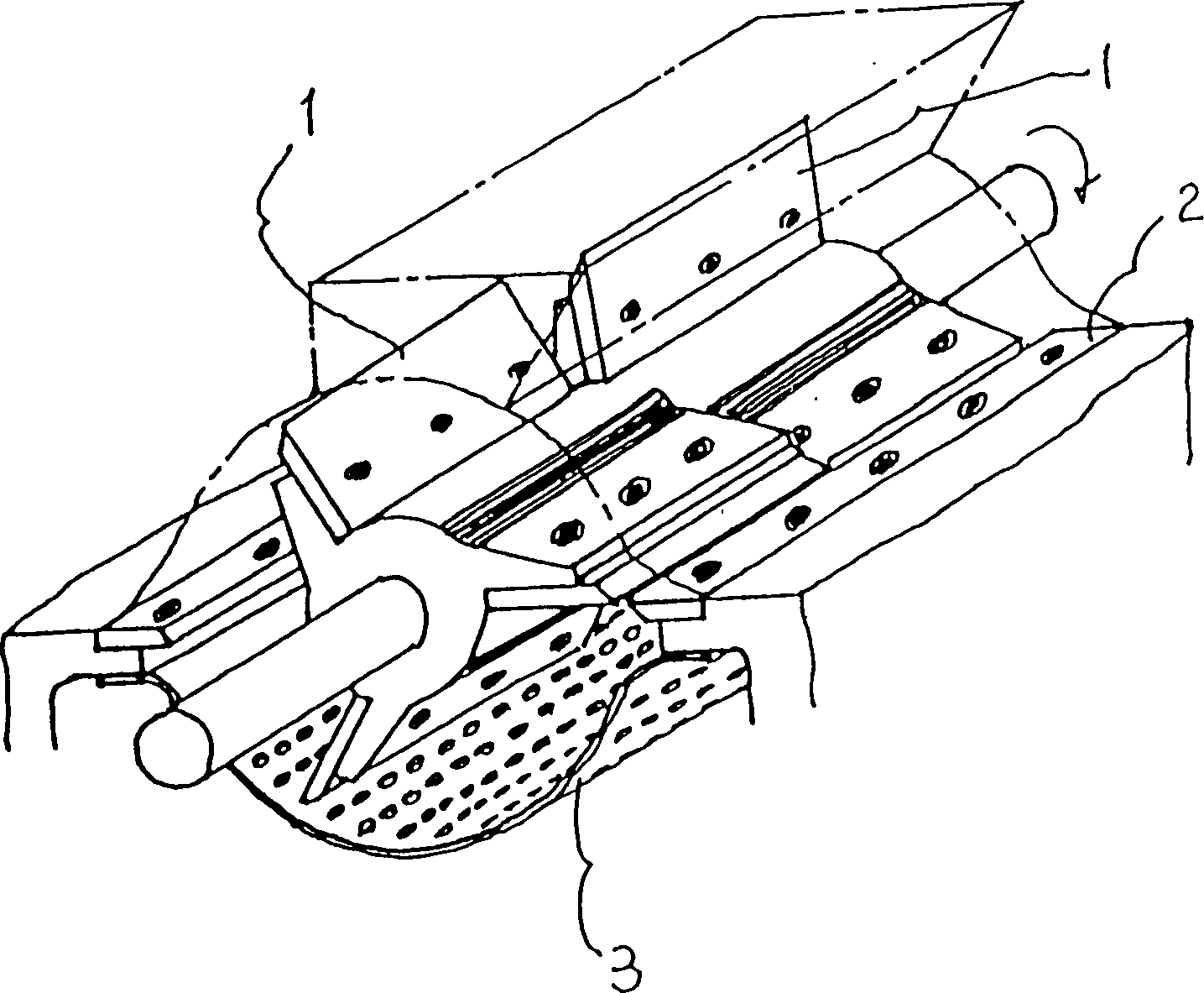

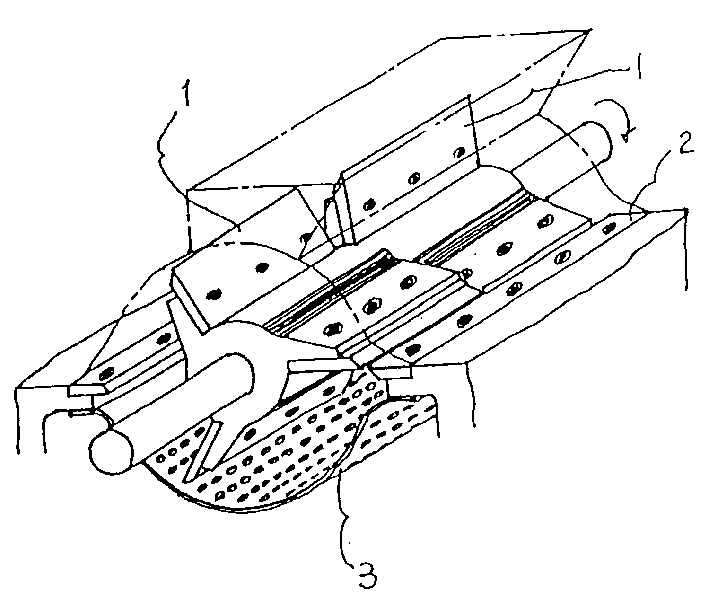

[0019] Corncobs are crushed with a rotary cutter with a rotating flat blade and a fixed blade shown in Figure 1 to obtain a bulk density of 0.18 and a particle size of 3-70 meshes. After drying such broken objects into three types of water content of 20%, 15%, and 10% in units of 20 kg, the dried objects were respectively put into metal molds (20 cm wide, 110 cm long, and 50 cm high), and the 150 kg / cm 2 The pressure is compressed into a column, and its specific gravity is measured according to the volume after 24 hours, and its consolidation is judged. The results are shown below.

[0020] Storage moisture content Specific gravity Consolidation

[0021] 20% 0.35 Crash

[0022] 15% 0.52 Weak

[0023] 10% 0.58 Good

[0024] In the above test, the sample with a water content of 20% collapsed when it was moved, and it was difficult to directly pack it into a bag and transport it. If it was transported in a container, the volume would not be reduced so much and the transport...

Embodiment 2

[0028] Corncobs are crushed with a hammer mill, and soybean stalks are likewise crushed. After drying to a water content of 12%, pressurization was carried out in 5 stages using the metal mold of Example 1 to adjust the characteristics of the compressed product.

[0029] The table below lists the bulk density and particle size of the pulverized material before pressurization.

[0030] Bulk density Particle size

[0031] Corn cob 0.35 4~50 mesh

[0032] Soybean stalk 0.25 below 2cm

[0033] Table 1 shows the characteristics of the compact.

[0034] corn on the cob

soybean stalk

pressure

Density

Adhesiveness

Density

Adhesiveness

10kg / cm 2

0.38

collapse

0.23

collapse

50kg / cm 2

0.42

collapse

0.24

collapse

100kg / cm 2

0.51

weak

0.35

collapse

150kg / cm 2

0.59

weak

0.42

weak

200kg / c...

Embodiment 3

[0039] Four beakers each having a capacity of 1000 cc were prepared, and 600 cc of water was filled in each.

[0040] The corncob pulverization in embodiment 1 and embodiment 2 and its addition 150kg / cm 2 The compacted matter under pressure was dispersed, and 60 g was added to the top of the water in each beaker, and the time until the upper part of the dispersed matter floating on the water was completely absorbed was measured, and the results are shown below.

[0041] Pulverized matter Dispersion

[0042] Example 1 12 points 1.5 points

[0043] Embodiment 2 25 minutes 5 minutes

[0044] From the above, it can be seen that the dispersion of the compacted material is more improved in water absorption than the pulverized material before pressurization. In particular, the sample crushed by cutting in Example 1 is more obvious than the sample crushed by a pulverizer in Example 2, and the water absorption time is shortened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com