Capillary column testing optical system calibration method and special device

An optical system and capillary column technology, applied in measurement devices, scientific instruments, instruments, etc., can solve the problems of beam scattering, non-negligibility, etc., and achieve the effect of strong flexibility, simple calibration, and solving the difficulty of optical calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

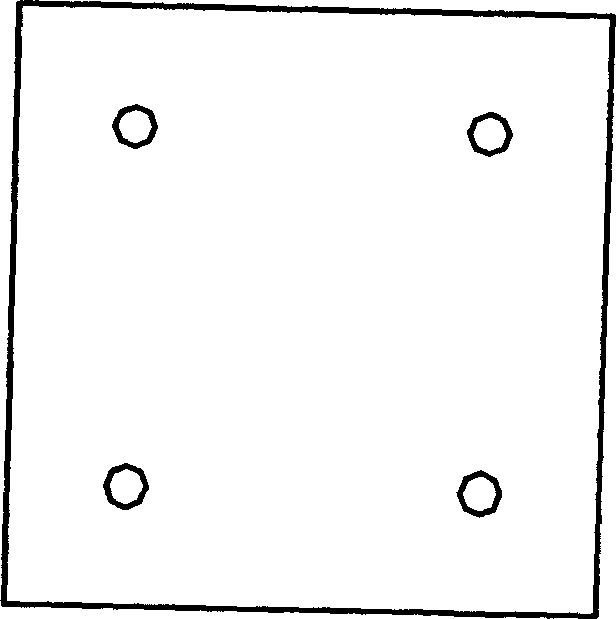

[0018] A capillary on-column detection cell was made by using the calibration auxiliary device (inlaid structure type in V-shaped groove), and the polymer material tube was made of polytetrafluoroethylene, combined with capillary column liquid chromatography, and benzene compounds were used as detection samples. performance of the system, the results are shown in Figure 6 . The results show that the calibration auxiliary device can effectively meet the requirements of optical calibration, and is easy to operate and has good repeatability. The chromatographic conditions are: stationary phase, KromasilC 18 (5μm); mobile phase, methanol: water = 80:20; flow rate, 8μL / min;, analytical column, 25cm×0.32mm; connecting tube and detection cell: 0.1mm i.d; Figure 6 Middle peaks 1, 2, 3, and 4 are benzene, toluene, naphthalene, and biphenyl, respectively.

Embodiment 2

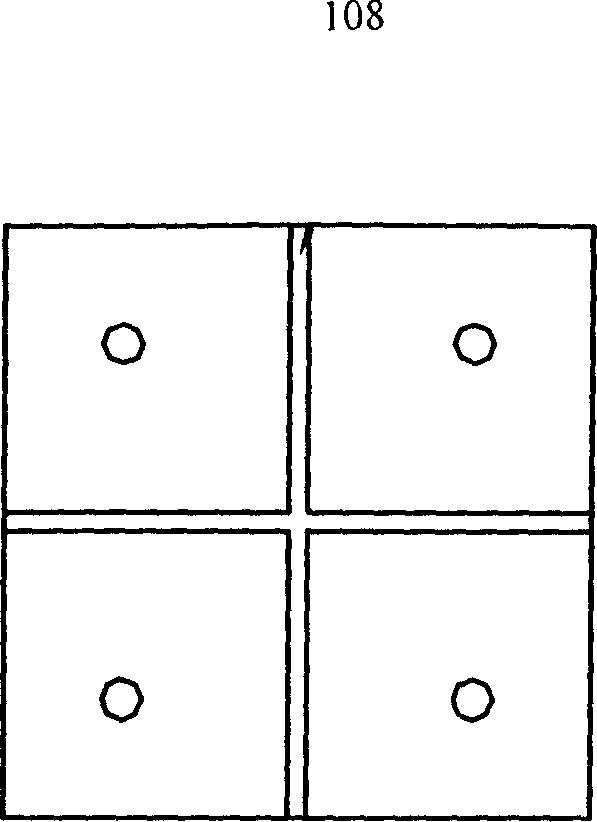

[0020] Using the calibration auxiliary device (four-way structure type), a capillary on-column detection device was fabricated. The main part of the four-way cross structure is made of metal, and the polymer material is made of PEEK tube. The test conditions are the same as above. see results Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com