Multicomponent mixed work medium throttling refrigerant applicable to medium-low temperature zone

A multi-component mixed working medium and refrigerant technology, applied in the field of cryogenic refrigeration, can solve the problems of the mixed working medium cannot operate efficiently, the operating temperature range is narrow, and the efficiency is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in further detail below in conjunction with the drawings and examples.

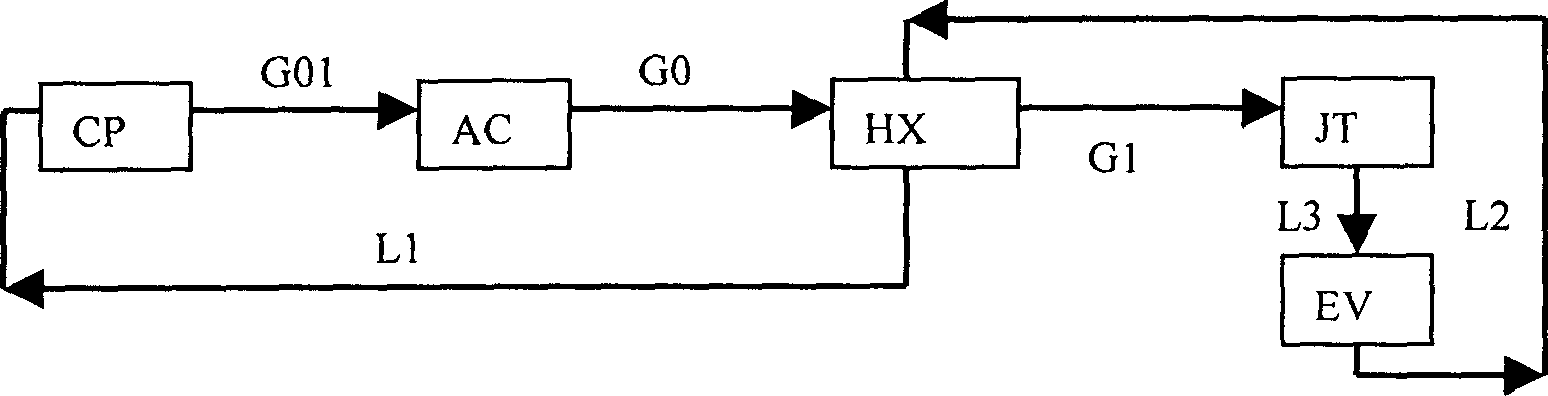

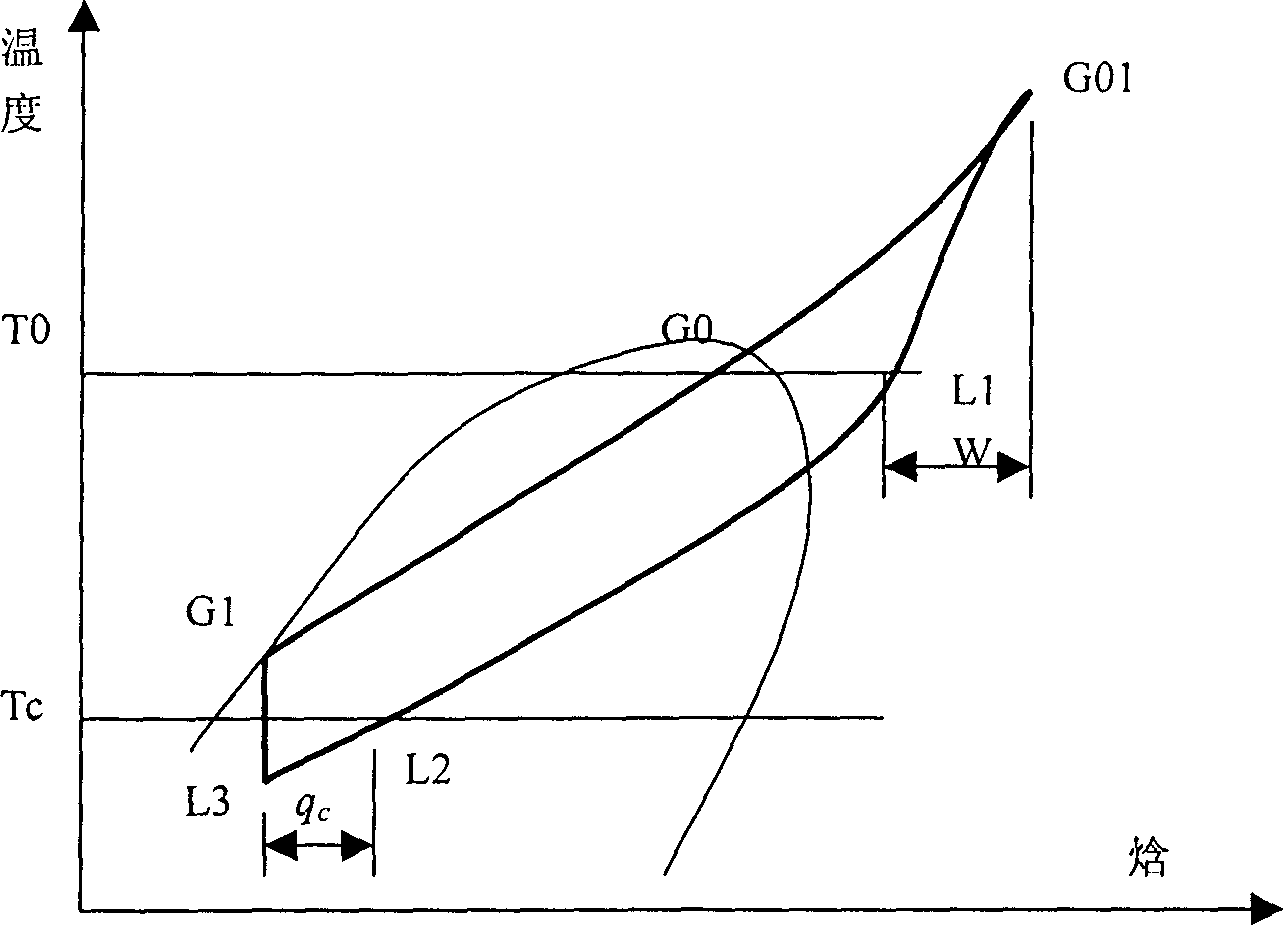

[0072] combine figure 1 and image 3 Specifically clarify the thermodynamic working process of the mixed working medium throttling refrigerant proposed by the present invention:

[0073] The mixed working medium throttling refrigerant of the present invention enters the compressor CP from the state L1 and is compressed to the state G01; then enters the cooler AC to cool to the state G0; enters the regenerative heat exchanger HX and is further cooled to G1; then passes through The throttling element JT becomes L3 after throttling; enters the evaporator EV, extracts cooling capacity and becomes L2; b then enters the recuperation heat exchanger HX for reheating, returns to the state L1, and completes a thermodynamic cycle.

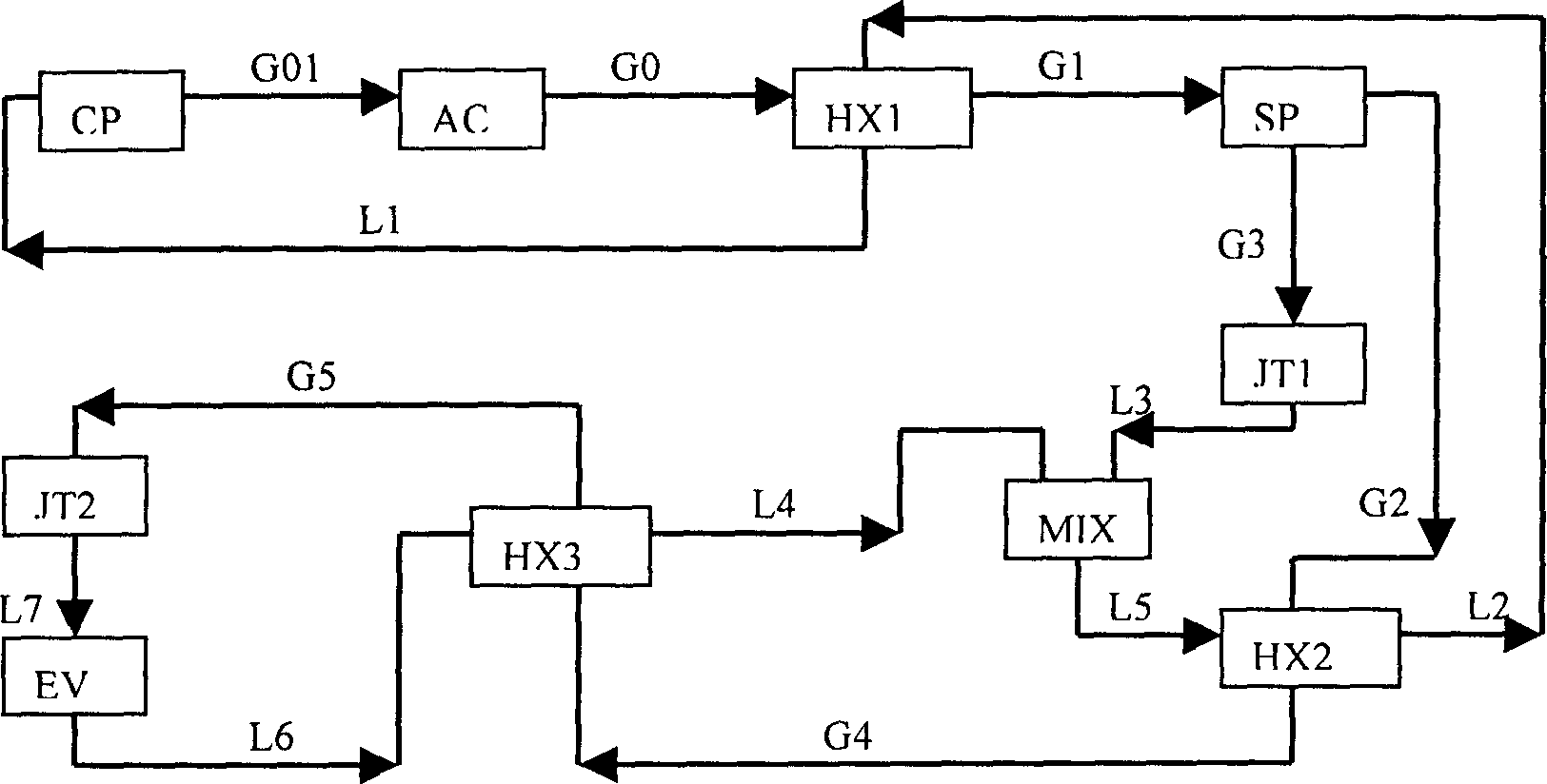

[0074] for figure 2 The thermodynamic cycle shown has the same basic working process, except that one stage of vapor-liquid separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com