Polyurethane foam as well as preparation method and application thereof

A polyurethane foam and foaming agent technology, applied in the field of polyurethane foam and its preparation, can solve the problems of not showing high strength performance, achieve low steam pressure, increase enterprise benefits, and improve compression resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

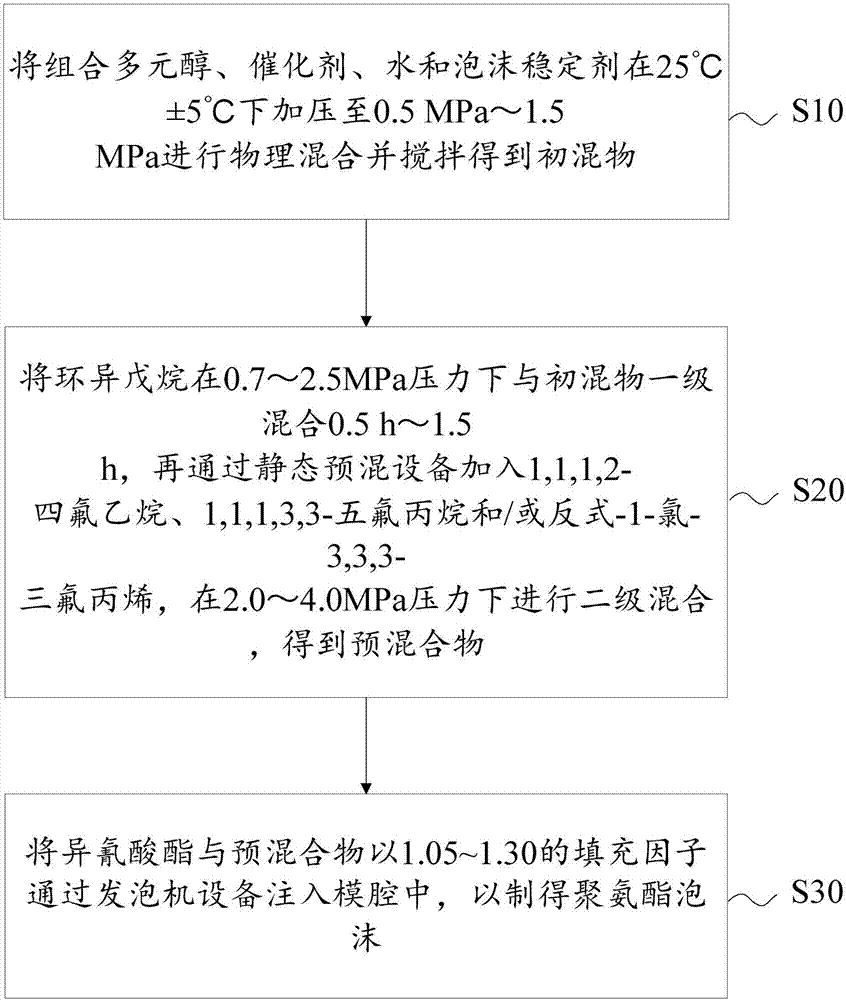

Method used

Image

Examples

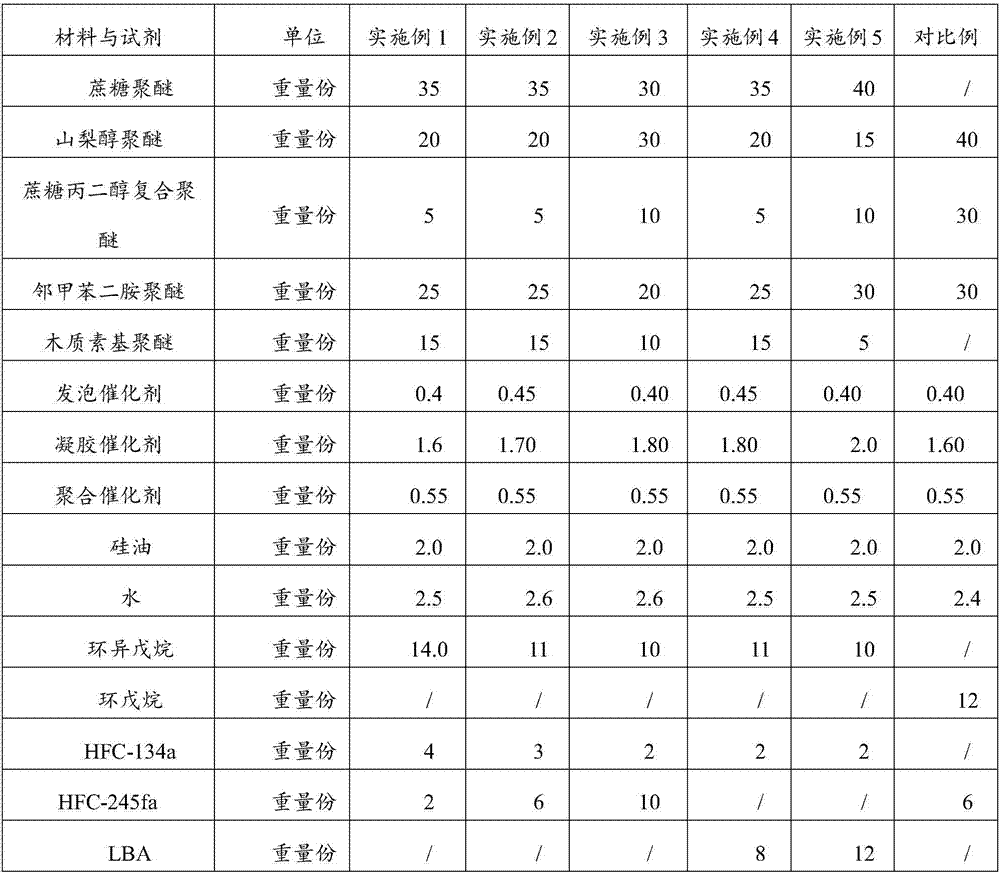

Embodiment 1-5 and comparative example 1

[0093] In Examples 1-5, by changing the ratio of polyol components and the ratio of each component in the composite catalyst, polyurethane foam with ultra-low density, high strength, excellent thermal insulation performance and good mold release performance can be prepared, as shown in the table below. Wherein, the polyol composition of the comparative example does not contain sucrose and lignin-based polyol.

[0094] Table 1 Comparison of composition and foam performance of the combined polyether raw materials of Examples 1-5 and Comparative Example 1

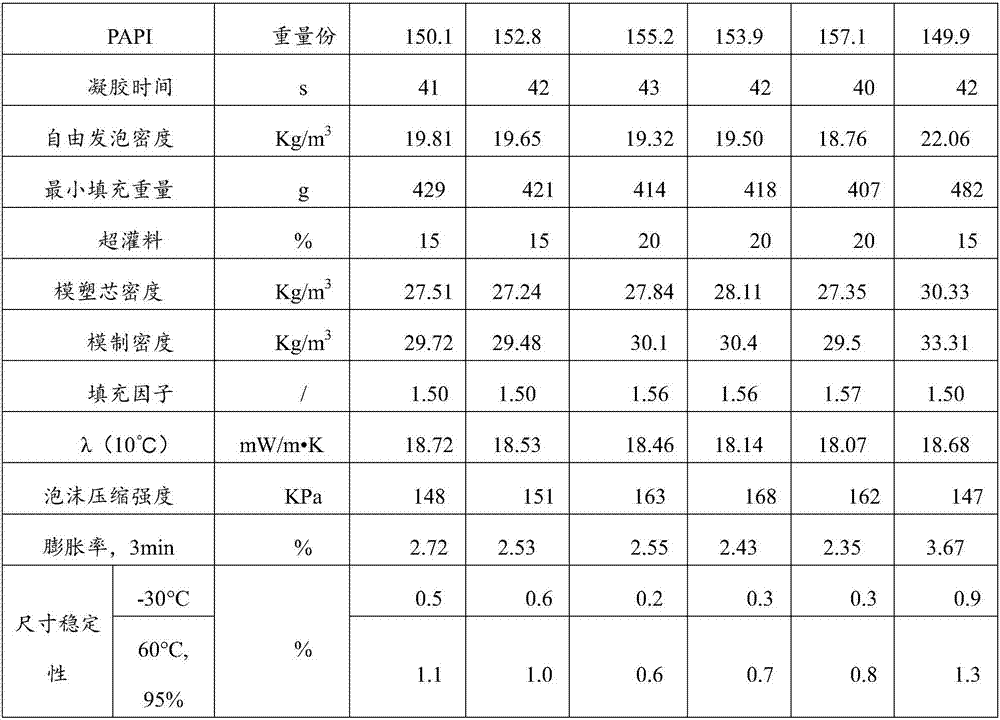

[0095]

[0096]

[0097] As can be seen from Examples 1-5 in Table 1 above, high-strength polyether polyols containing a large number of benzene rings and aromatic amine polyether polyols can be used to obtain high-strength , Polyurethane foam with good mold release properties. It can be seen from the above Table 1 that the comparative example does not contain sucrose and lignin-based polyols, the foam expansion rate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com