Ink jet recording medium

An inkjet recording medium, a technology of dispersing resin, applied in the direction of copying/marking method, coating, printing, etc., can solve the problems of unsatisfactory wear resistance and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

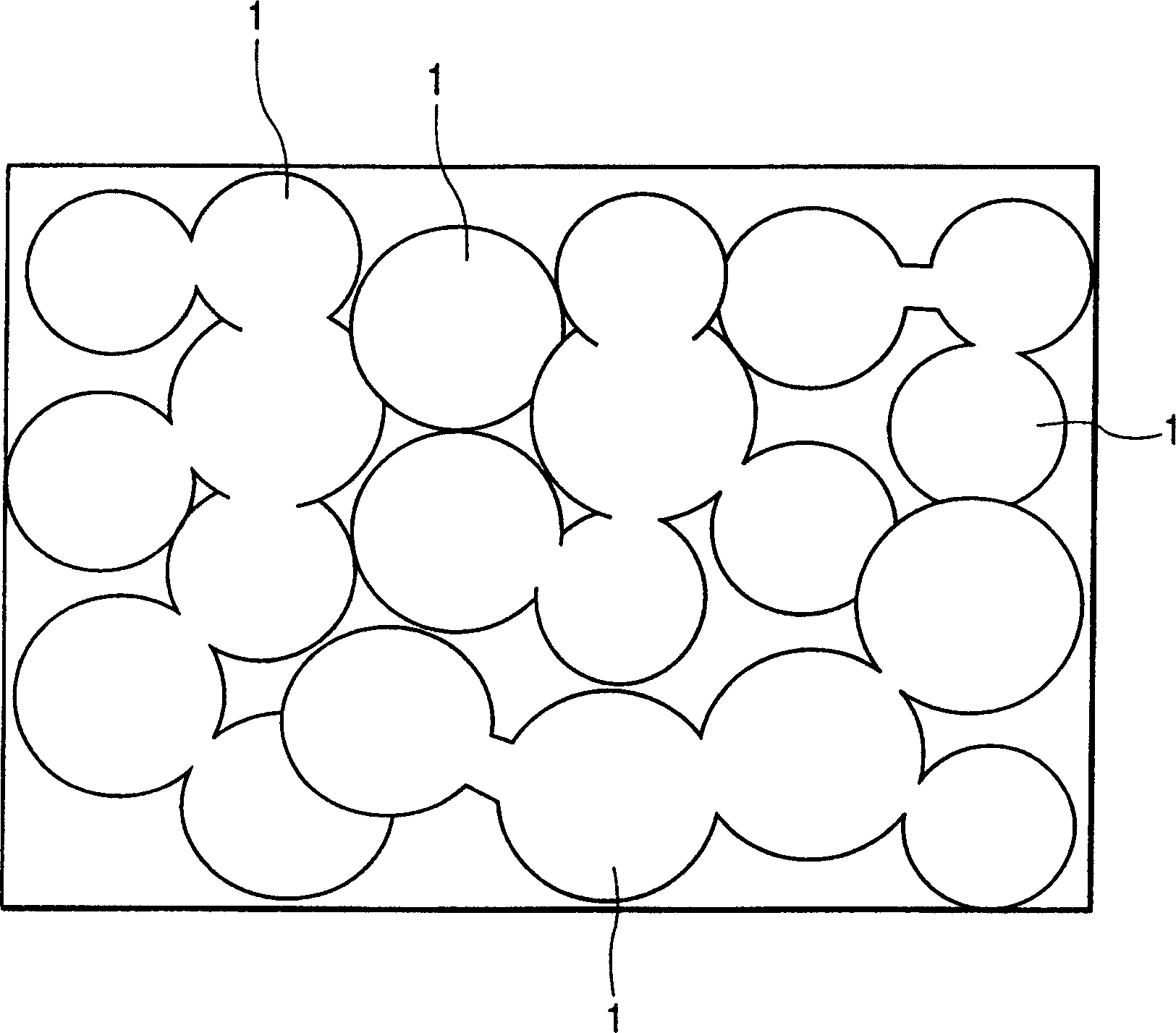

Image

Examples

Embodiment 1

[0081] A coated paper sheet as a substrate was prepared as follows. Prepared by mixing 100 parts by weight of granular barium sulfate with an average particle size of 0.6 μm obtained by reacting barium sulfate and barium chloride, 10 parts by weight of gelatin, 3 parts by weight of polyethylene glycol, and 0.4 parts by weight of chromium alum Coating liquid. Apply the coating liquid to a basis weight of 130 g / m 2 On a substrate sheet with a Bekk smoothness of 340 seconds, a dry thickness of 20 μm was obtained. The coated sheet was supercalendered to give a substrate with a surface smoothness of 400 seconds.

[0082] By mixing 100 parts by weight of vinyl chloride-vinyl acetate-acrylic acid copolymer (minimum film-forming temperature: 130° C., average particle size: 0.75 μm), and 10 parts by weight of styrene-acrylate copolymer (Movinyl 752, trade name, Hoechst Gosei K.K.; minimum film forming temperature: 30° C., average particle diameter: 0.1 μm) was mixed, and then the so...

Embodiment 2

[0103] The recording medium of the present invention was prepared in the same manner as in Example 1, except that acrylic acid-modified colloidal silica (Movinyl 8030, trade name, Hoechst Gosei K.K.; minimum film-forming temperature: 30° C., average particle size: 0.06 μm) was used instead Styrene-acrylate copolymer.

[0104] The porous layer thus obtained was observed by SEM, and it was confirmed to have partial fusion of the water-dispersible resin particles.

[0105] For this recording medium, printed matter was prepared and evaluated in the same manner as in Example 1. Table 1 presents the results.

Embodiment 3

[0107] A recording medium of the present invention was prepared in the same manner as in Example 1, except that a vinyl acetate-acrylic acid copolymer (Movinyl 630, trade name, Hoechst Gosei K.K.; minimum film-forming temperature: 19° C., average particle size: 0.15 μm) was used instead Styrene-acrylate copolymer.

[0108] The porous layer thus obtained was observed by SEM, and it was confirmed to have partial fusion of the water-dispersible resin particles.

[0109] For this recording medium, printed matter was prepared and evaluated in the same manner as in Example 1. Table 1 presents the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com