Pressure swing adsorption method for distilling olefin or ethane from gas mixture

A technology of pressure swing adsorption and mixed gas, applied in the direction of absorption purification/separation, organic chemistry, etc., can solve the problems such as difficult to purify olefins, and achieve the effect of improving purity, enhancing separation effect and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw material gas is catalytic dry gas, and its composition is as follows:

[0038] Components: CH 4 C 2 h 4 C 2 h 6 C 3 h 8 C 3 h 6

[0039] Volume % (V): 37 18 18 0.4 2

[0040] Components: Isobutene n-Butene Butene C5

[0041] Volume % (V): 0.6 0.3 1.3 0.2

[0042] Component: H2 CO 2 CO and the rest are N 2

[0043] Volume % (V): 20 1.1 0.1

[0044] According to the composition of the above-mentioned raw materials, the PSA method in this embodiment adopts the PSA process flow as shown in Figure 1 and the process sequence table shown in Figure 3 .

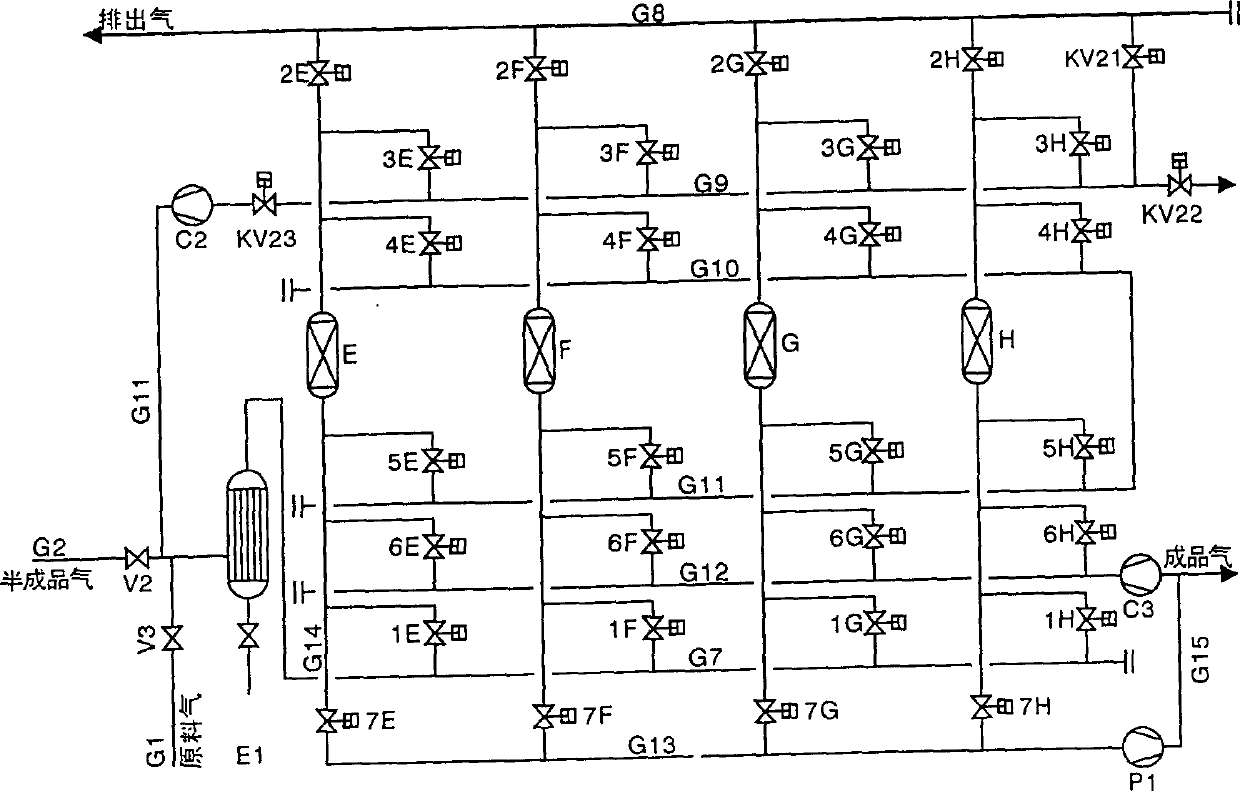

[0045] The pressure swing adsorption system of this embodiment has four tower-type adsorption beds E, F, G, H, and raw gas pipeline G1, inlet pipe G7, replacement gas inlet pipe G12, replacement gas outlet pipe G9, pressure equalization Pipes G10 and G11, waste gas discharge pipe G8, vacuum pipe G13, E1 is the feed gas heater, C2 is the replacement exhaust gas pressurizer, C3 is th...

Embodiment 2

[0071] The feed gas of this embodiment is the same as that of Embodiment 1, and the extracted product is pure ethylene.

[0072] In this embodiment, two stages of pressure swing adsorption are operated in series. The first stage is a pretreatment device, which is used to remove propylene and olefins with a molecular weight greater than propylene, and also to remove propylene and alkanes above propane. The ethylene-containing mixed gas from which propylene, propane and above hydrocarbons have been removed enters the second stage of pressure swing adsorption to purify ethylene.

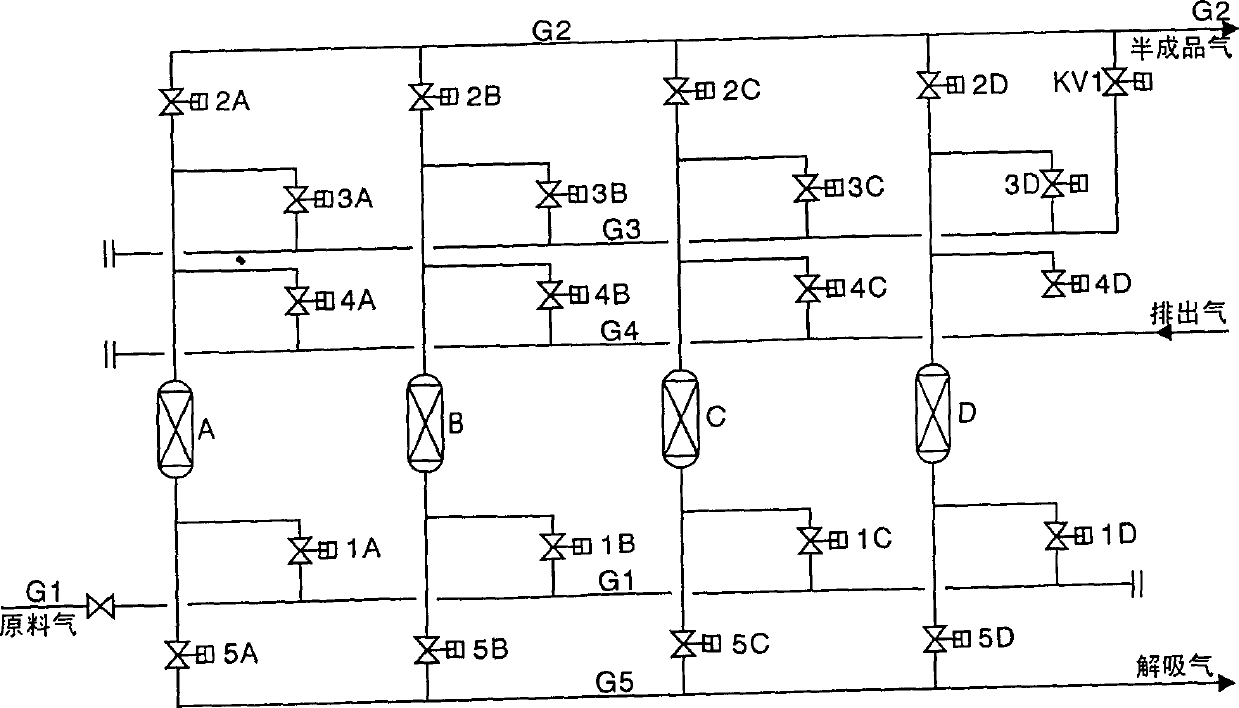

[0073] The process flow chart of the pressure swing adsorption pretreatment device in this embodiment is shown in Figure 2, and the process flow chart 1 of the pressure swing adsorption device for extracting ethylene. The ethylene-containing mixed gas from which propylene and other components have been removed by the pretreatment device enters the ethylene extraction pressure swing adsorption device thr...

Embodiment 3

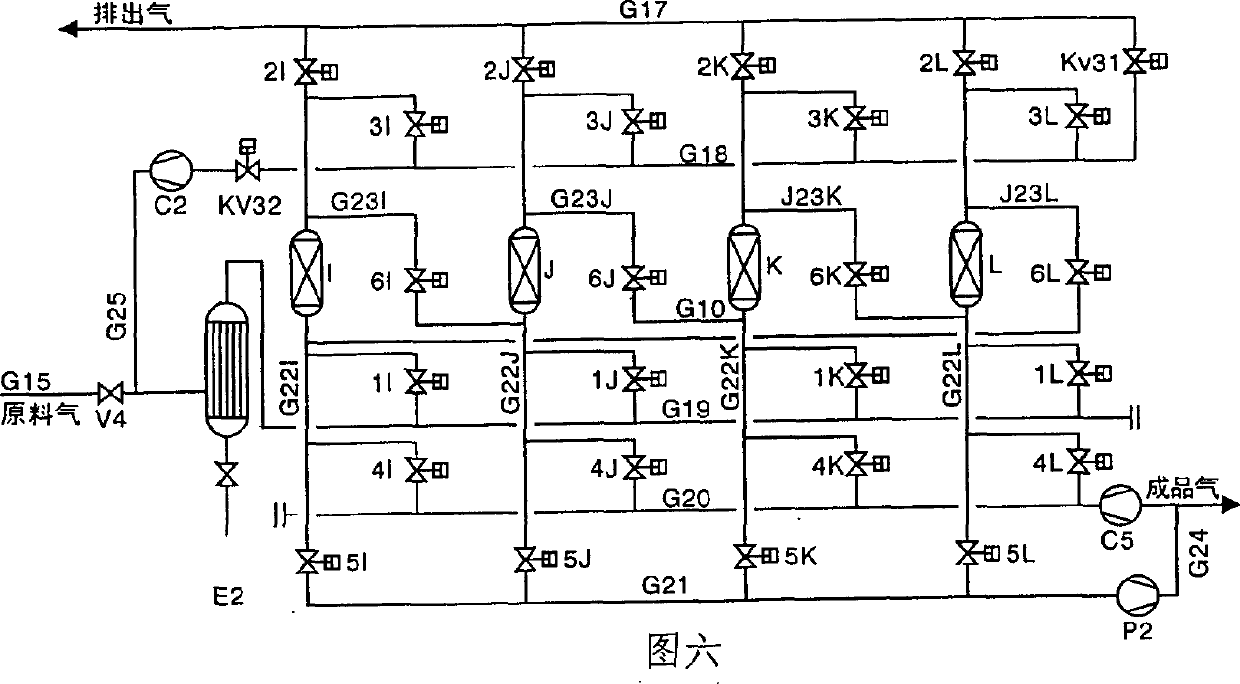

[0101]The raw material gas in this example is the same as that in Example 1, and the olefins are extracted by adopting a process of serial replacement steps consisting of two adsorption bed replacement steps connected in series. The process flow of this embodiment is shown in Figure 6, and the process sequence is shown in Figure 5. The adsorption towers I~L are filled with Cu + the adsorbent. Now take Tower I as an example to illustrate this embodiment.

[0102] 1. Adsorption (A)

[0103] The raw material pressure is 0.1-0.2Mpa, enters the heater E2 through V4 and heats up to 130°C, and enters the adsorption tower I through the pipeline G19 and the program-controlled valve 1I. 2I discharges non-adsorbed gas. When the adsorption front of olefins reaches a certain position in the tower, close 1I and 2I.

[0104] 2. Equal pressure drop (ED)

[0105] Open the program-controlled valve 6I, press all the gas in the adsorption bed I into the J tower to increase the pressure of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com