Luminuous diode packaging structure and its method

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problem of difficulty in accurately controlling accuracy and uneven color temperature directly above the tube chip and at the junction of the chip and the conical reflector cup, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

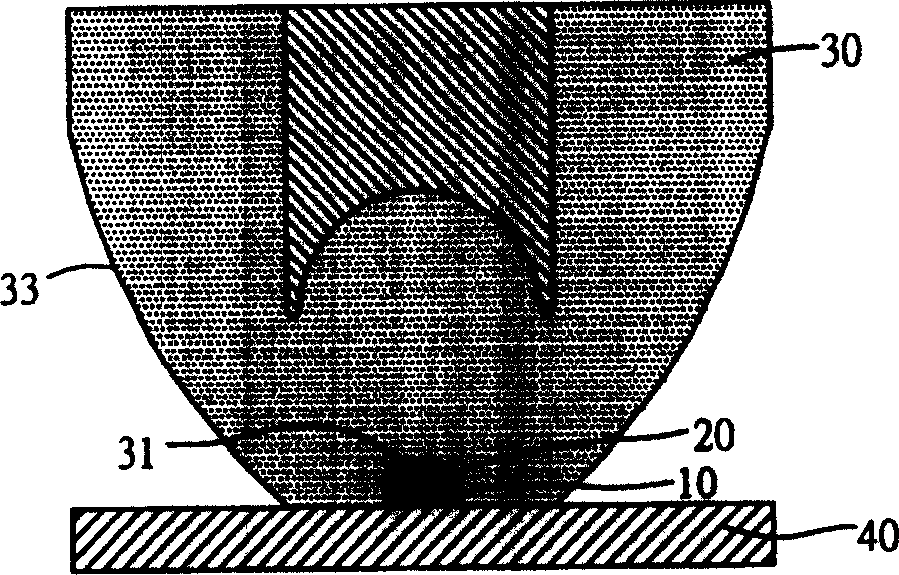

[0021] Please refer to figure 1 , which is a schematic cross-sectional view of a light emitting diode package structure according to an embodiment of the present invention. It includes a light emitting diode 10, a condenser lens 30 and a fluorescent powder adhesive film 20 filled between them. The light-emitting diode connected to the substrate 40 is housed in the cavity 31 of the condenser, and at the same time, there is an appropriate amount of fluorescent powder adhesive film 20 in the cavity 31 to cover the surface of the light-emitting diode 10, and the pre-formed cavity 31 is used to control the fluorescence. The thickness and shape of the powder glue film 20.

[0022] Such as figure 1 As shown, the concentrator 30 of the embodiment of the present invention is a tapered transparent plastic component, which can be made by plastic injection molding. The shape of the diode and the required thickness of the phosphor adhesive film 20 are designed in accordance with the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com