Direct injection diesel engine premixed combustion method and its device

A pre-mixed combustion and diesel engine technology, which is applied to fuel injection devices, combustion engines, charging systems, etc., can solve problems such as lack of information, high cost, and complicated control systems, so as to reduce harmful emissions of soot and NOx and improve The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

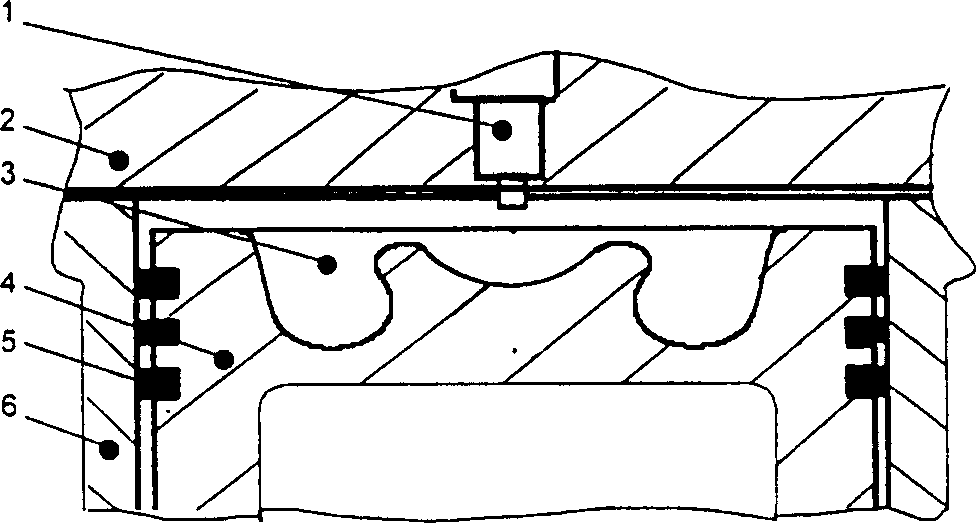

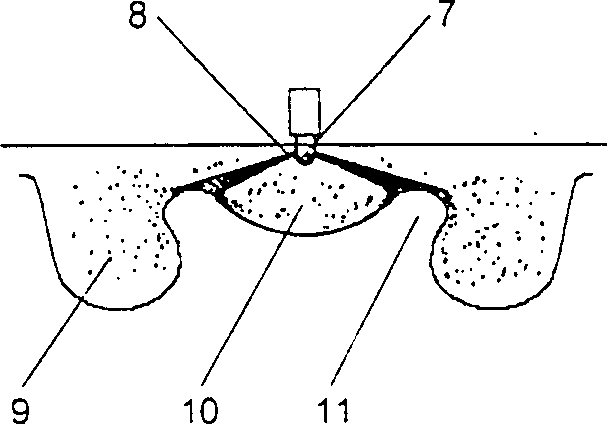

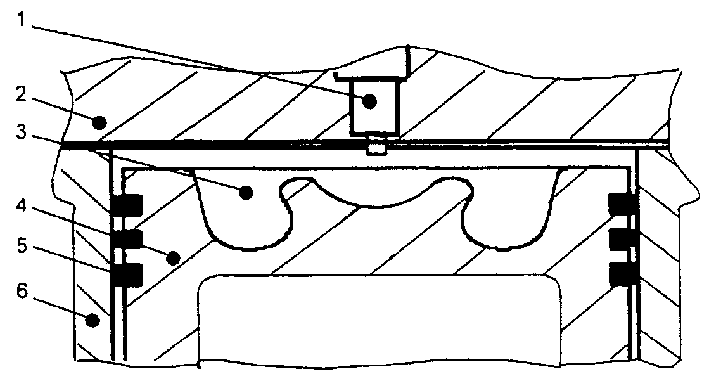

[0018] exist figure 1 Among them, the direct-injection diesel engine combustion system of the present invention includes: a fuel injector 1, a cylinder head 2, a combustion chamber 3, a piston 4, a piston ring 5, and a cylinder 6. exist figure 2 Among them, the combustion chamber space of the present invention is divided into two parts, the outer annular combustion chamber 9 and the central combustion chamber 10, the two are separated by an annular cylinder 11, and the height of the annular cylinder 11 is 2 / 3-3 / 4 of the height of the entire combustion chamber . The cross-sectional shape of the annular cylinder 11 is arc-shaped. The surface of the annular cylinder 11 is smoothly connected with the outer annular combustion chamber 9 and the central combustion chamber 10 . The central combustion chamber 10 is an inverted curved surface rotation body, and may also be an arc surface rotation body, a paraboloid rotation body or a cone. Above the center of the combustion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com