Method for producing image-forming apparatus

A method for generating images and a technology for image generation, which can be applied in the directions of image/graphic display tubes, image copiers, discharge tubes, etc., and can solve the problems of increased and inappropriate factors restricting the structure of display devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

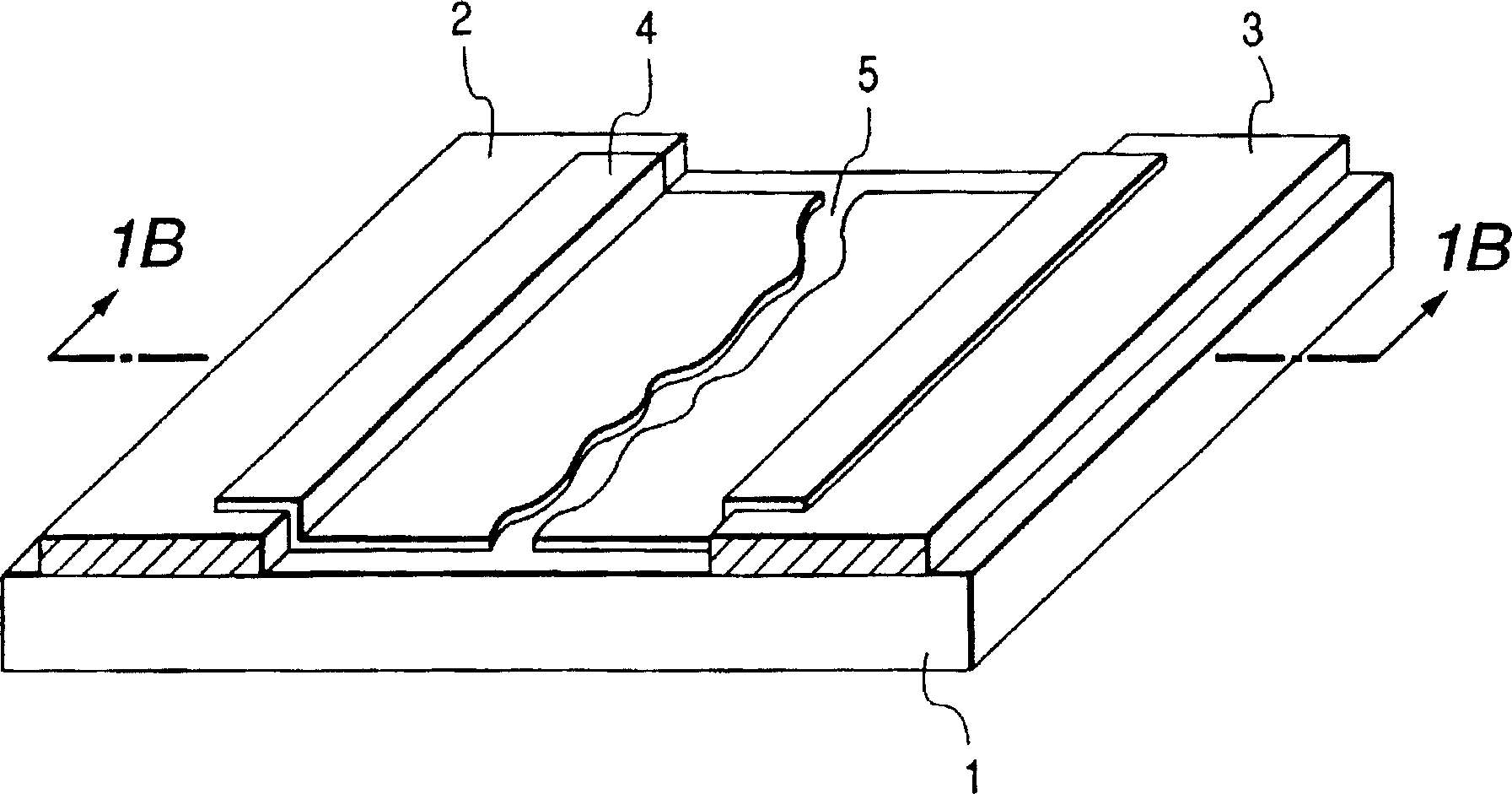

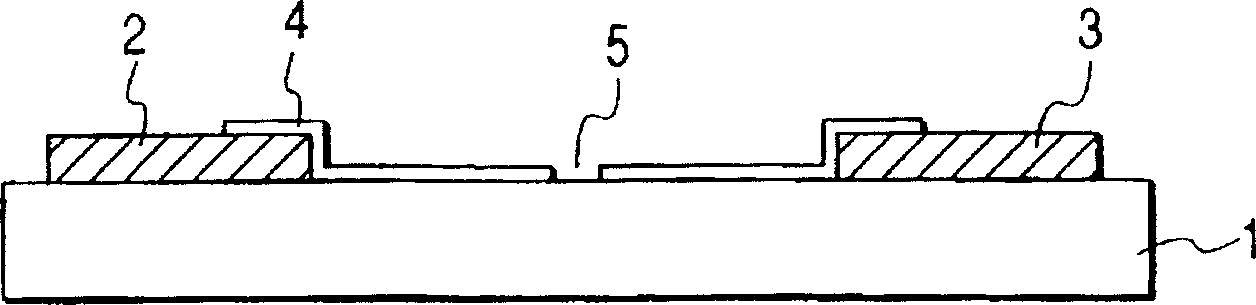

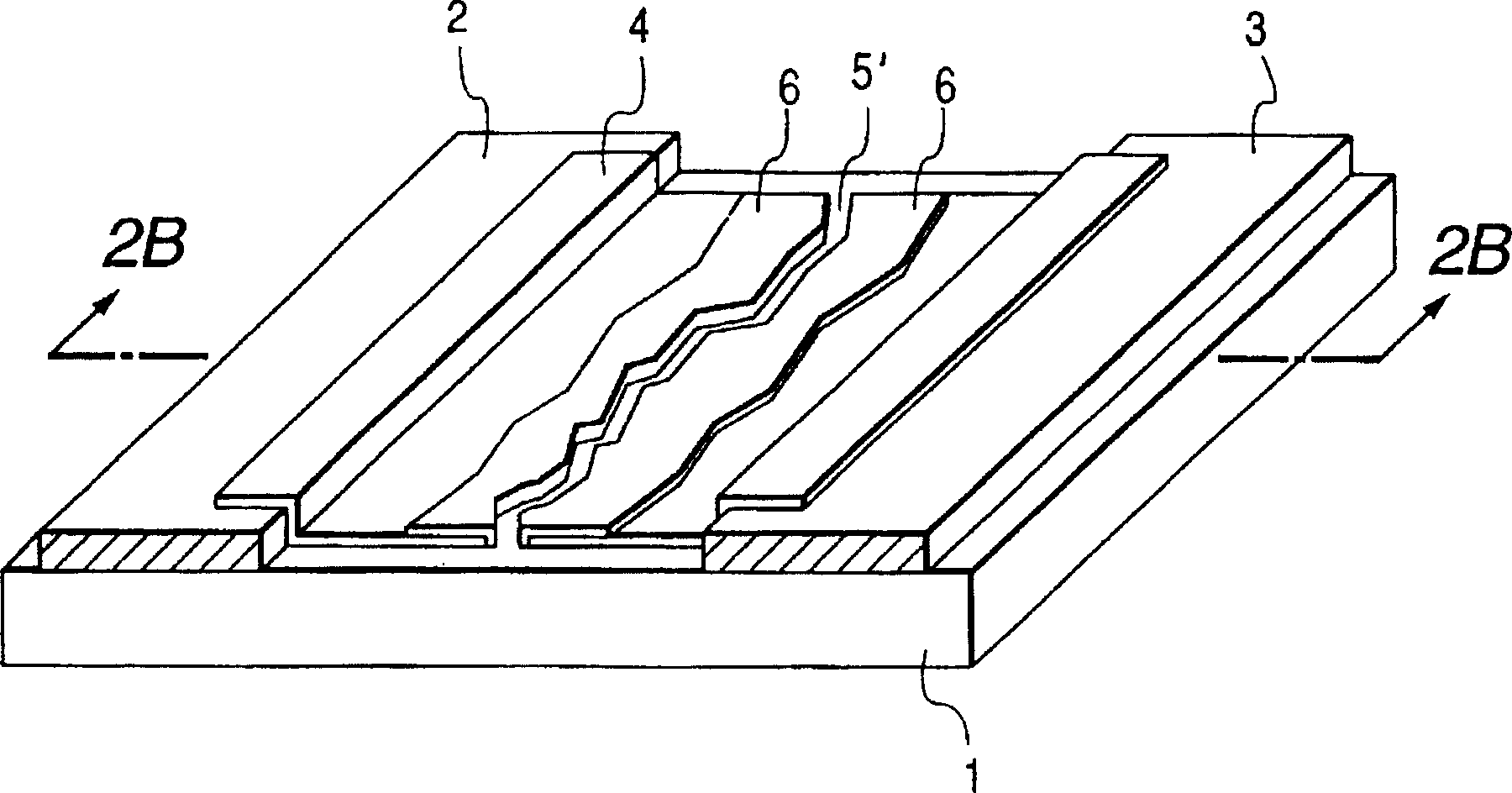

Image

Examples

example 1

[0138] This example is an example of an aging step according to the present invention. In the case of manufacturing an image forming apparatus in which a large number of surface-conduction electron-emitting devices are arranged in a simple matrix layout on an electron source substrate, the aging process is performed by using the manufacturing equipment while the getter is evaporating. and encapsulation performed before.

[0139] Figure 13 is a schematic diagram of an aging apparatus for performing an aging step according to the present invention, for a panel container 101 of an image forming apparatus.

[0140] exist Figure 13 Among them, 101 is a screen container, 121 is an electron source drive control unit, 122 is a data acquisition / analysis unit, 123 is an electron source drive unit, 124 is a drive current measurement unit, 125 is an anode current measurement unit, 126 is a drive signal bus, 127 is the device current bus, and 128 is the transmit current signal bus.

...

example 2

[0184] This example is a manufacturing period of an image forming apparatus in which a large number of surface conduction electron emission devices are arranged in a simple matrix layout on an electron source substrate according to the present invention, by using the image forming apparatus, after the getter evaporation and packaging steps An example of the aging procedure.

[0185] A picture display panel 101 using a large number of surface-conduction electron-emitting devices was fabricated in the same manner as in Example 1. In this example, the materials and dimensions used for the display screen 101 are the same as those in Example 1, except that the x-direction interval between the electron-emitting devices and the phosphor member interval of each color on the panel are 360 μm, however, in the display screen 101 In the generation step, the encapsulation / getter evaporation step performed after the stabilization step does not carry out the aging step.

[0186] the...

example 3

[0200] The image forming apparatus produced in this example has the same structure as the image forming apparatus of Example 2 and all the processing conditions of each step, except for forming operation, energizing operation, stabilizing operation, gettering operation, aging operation, and encapsulation. And outside of the generation step of the image forming apparatus performed after the pumping.

[0201] The image-forming apparatus of this example produced as described above was driven in the same manner as in Example 2, and the emission current Ie therein was measured and compared with that of the Example 2 control. The results are shown in Table 3.

[0202] (μA)

[0203] As can be seen from the table, the image forming apparatus obtained through the aging step of the present invention, compared with the image forming apparatus of the example control object, has formed a high-quality display image (very little deviation) from the start of driving to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com