Double-vortex smoke washing device

A washing device and flue gas technology, which is applied in the direction of combination device, liquid separation agent, dispersed particle separation, etc., can solve the problems of affecting the effect of desulfurization and dust removal, difficult removal of dust sludge, and reduction of flue gas velocity, etc., to achieve removal Good effect, large specific surface area, low water entrainment in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

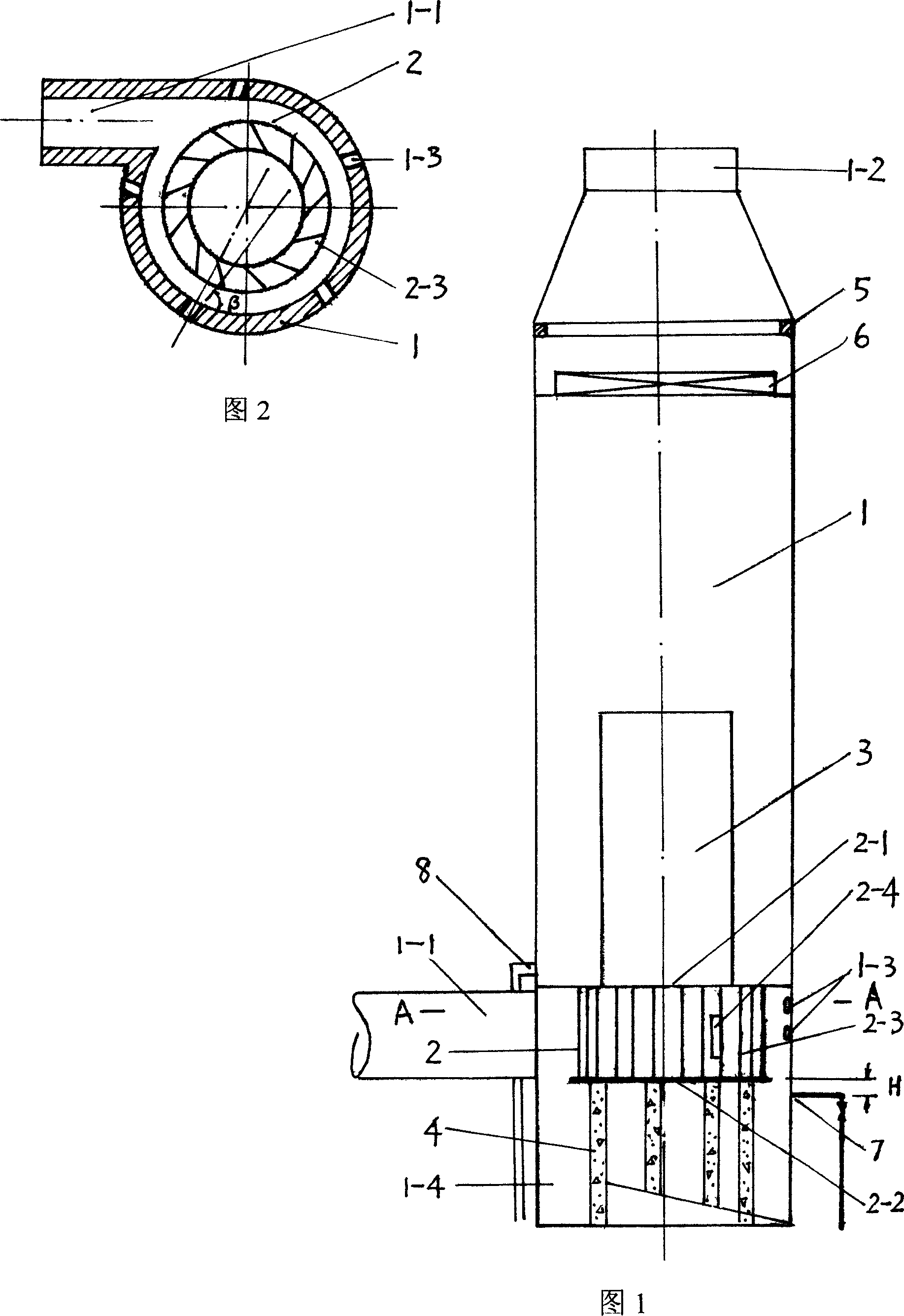

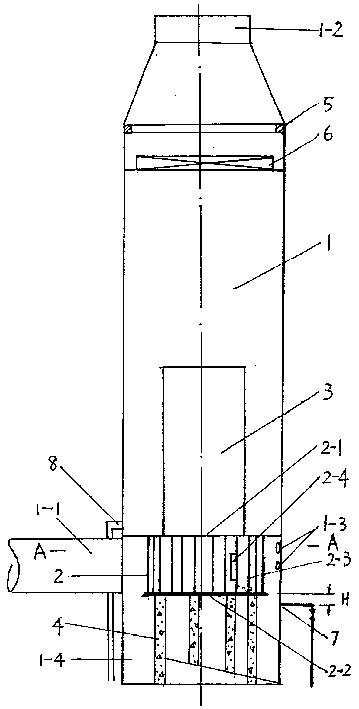

[0014] Example. As shown in Fig. 1, the double-vortex flue gas scrubber of this example has a main cylinder 1 with a height of 1600 cm and an inner diameter of 280 cm, and is provided with inlet and outlet flue gas ports 1-1 and 2-2. The vortex device 2 is directly built on the lower part of the main cylinder. There is no gap between the upper plate 2-1 and the main cylinder. The lower plate 2-2 is supported by a number of columns 4. The number and angle of the deflectors and the deflectors The height, width and middle through hole are related to the size of the main cylinder and the flue gas volume of the boiler. As shown in Fig. 2, five alkaline liquid nozzles 1-3 are evenly distributed in two layers on the main cylinder body 1, the angle β between the nozzles and the inner wall of the main cylinder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com