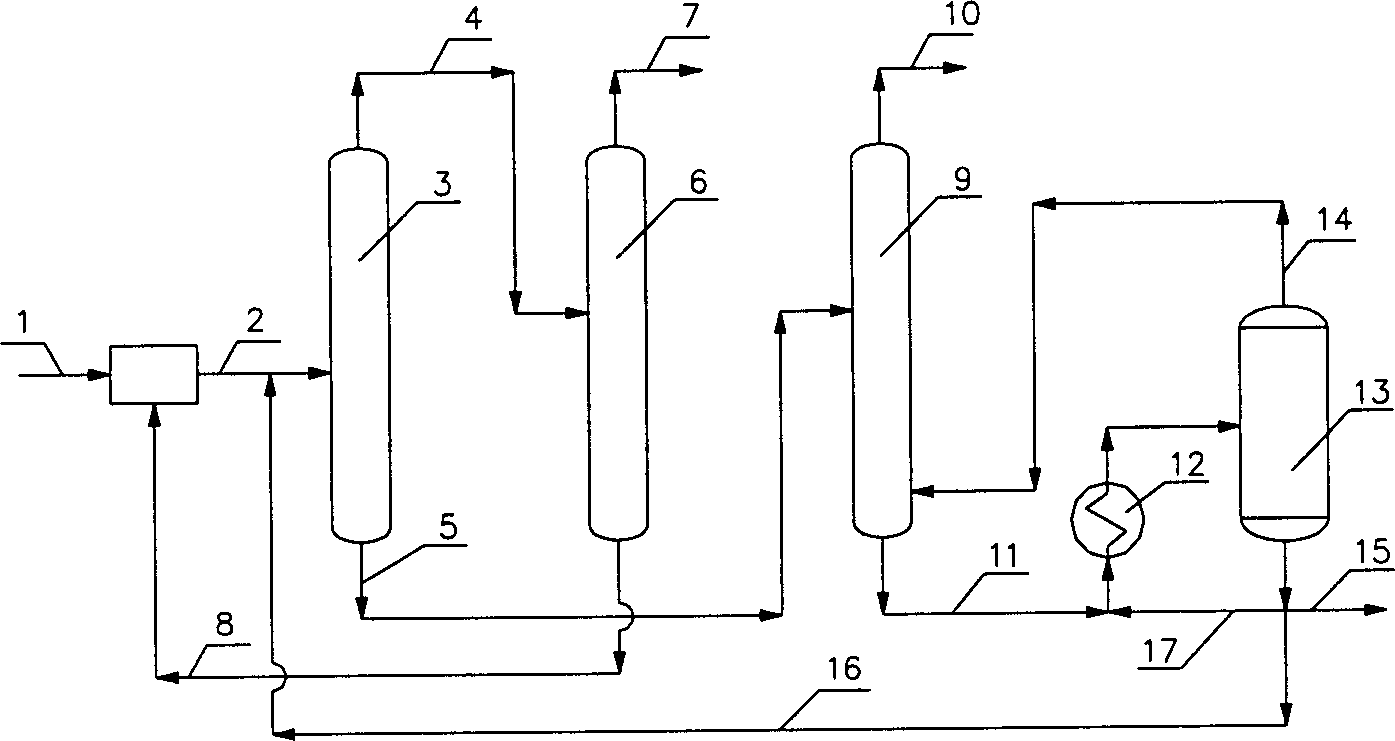

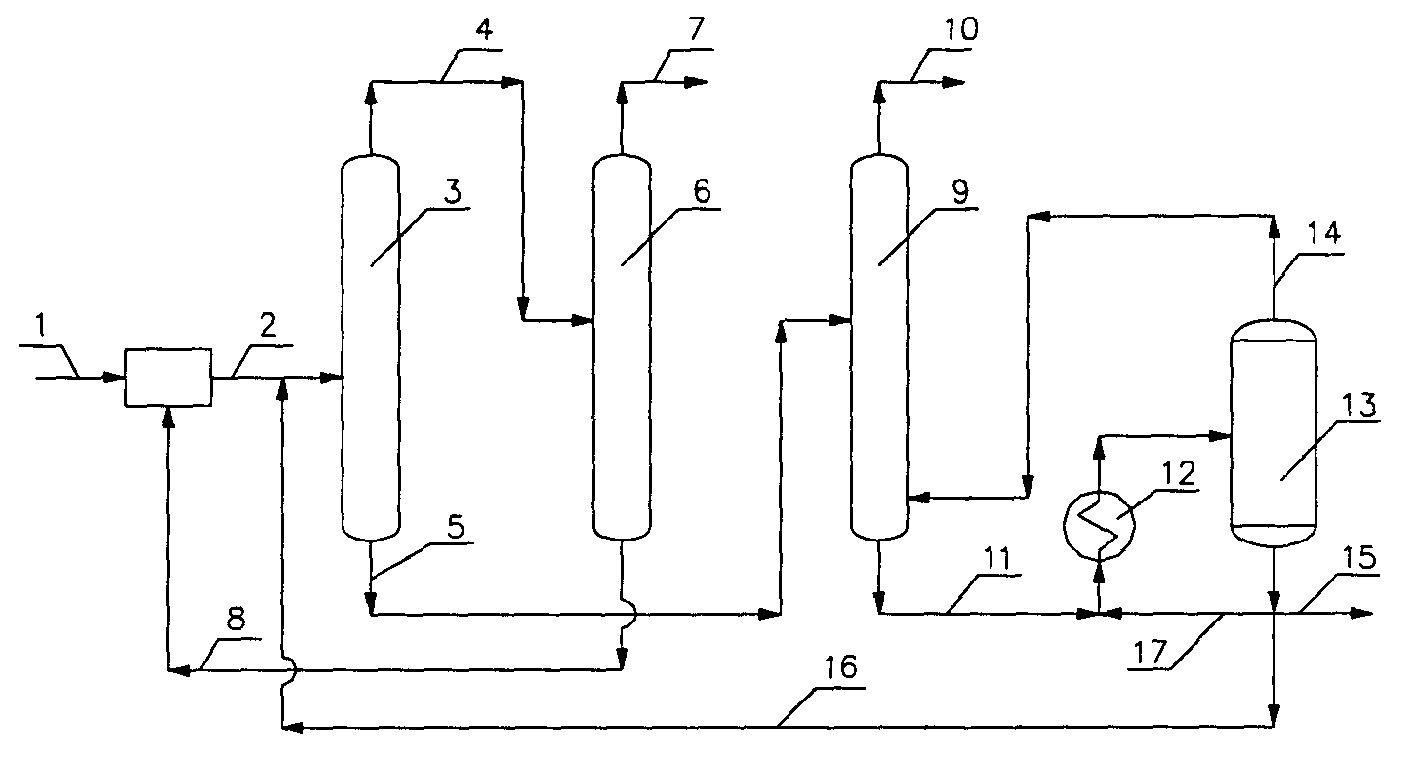

Styrene separation process

A separation method and technology of styrene, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of large loss of styrene, large loss of styrene, poor evaporation effect, etc., to reduce equipment investment, not easy to deactivate, The effect of improving the flash evaporation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Crude styrene raw material liquid is composed of the following mass flow components: benzene 13.86 kg / h, toluene 59.68 kg / h, non-aromatic 2.78 kg / h, ethylbenzene 1345.85 kg / h, styrene 2533.7 kg / h, p-xylene 0.35 kg / h, m-xylene 0.17 kg / h, o-xylene 0.03 kg / h, cumene 0.02 kg / h, α-methylstyrene 4.91 kg / h, heavy components 65.80 kg / h, polymer 57.49 kg / hour and water 4.17 kg / hour. The crude styrene raw material liquid enters the middle part of the crude styrene separation tower, and the crude styrene fractionation tower is a packed tower with 80 trays in total, of which 27 trays are in the rectification section. The pressure at the top of the tower is 12KPa, and the temperature at the top of the tower is 71 ℃, the pressure of the tower bottom is 21KPa, the temperature of the tower bottom is 96°C, the reflux ratio of the top reflux liquid is 7.6, the temperature of the reflux liquid is 45°C, and the mass flow rate of the top material of the crude styrene separation tower is 8....

Embodiment 2

[0022] According to the conditions and steps of Example 1, only the pressure at the top of the crude styrene separation tower was changed to 15KPa, the temperature at the top of the tower was 75°C, the pressure at the bottom of the tower was 24KPa, the temperature at the bottom of the tower was 99°C, and the reflux ratio of the top reflux liquid was 8.0 , the temperature of the reflux liquid is 50°C, the total plate number of the crude styrene separation tower is 70, and the rectification section is 22 trays; the operating temperature of the flash tank is 120°C, the operating pressure is 30KPa, and the cycle is calculated by weight ratio To the amount of tar in the middle of the flash tank: the amount of tar discharged is 140: 1. As a result, the weight percent concentration of styrene in the crude styrene separation tower overhead material is 1.63%, and the weight percent concentration of styrene in the output tar 15 It is 4.98%, and the loss of styrene polymerization is 6.1 k...

Embodiment 3

[0024] According to the conditions and steps of Example 1, only the pressure at the top of the crude styrene separation tower was changed to 10KPa, the temperature at the top of the tower was 65°C, the pressure at the bottom of the tower was 18KPa, the temperature at the bottom of the tower was 90°C, and the reflux ratio of the top reflux liquid was 7.0 , the reflux liquid temperature is 40 ℃; the operating temperature of the flash tank is 140 ℃, and the operating pressure is 15KPa, and the amount of tar in the middle part of the flash tank is circulated by weight ratio: the amount of tar discharged is 80: 1, and the result is: crude The weight percent concentration of styrene in the top material of the styrene separation tower is 0.74%, the weight percent concentration of styrene in the discharged tar 15 is 3.69%, and the styrene polymerization loss is 2.8 kg / ton of styrene product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com