Method for improving operating performance of intake filtration and reverse osmosis process utilizing magnetization pretreatment

A technology of operating performance and reverse osmosis, which is applied in the field of water treatment technology and material separation, can solve the problems of operator safety hazards, safety hazards, and high costs, and achieve the effects of lengthening cleaning cycles, prolonging service life, and low investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

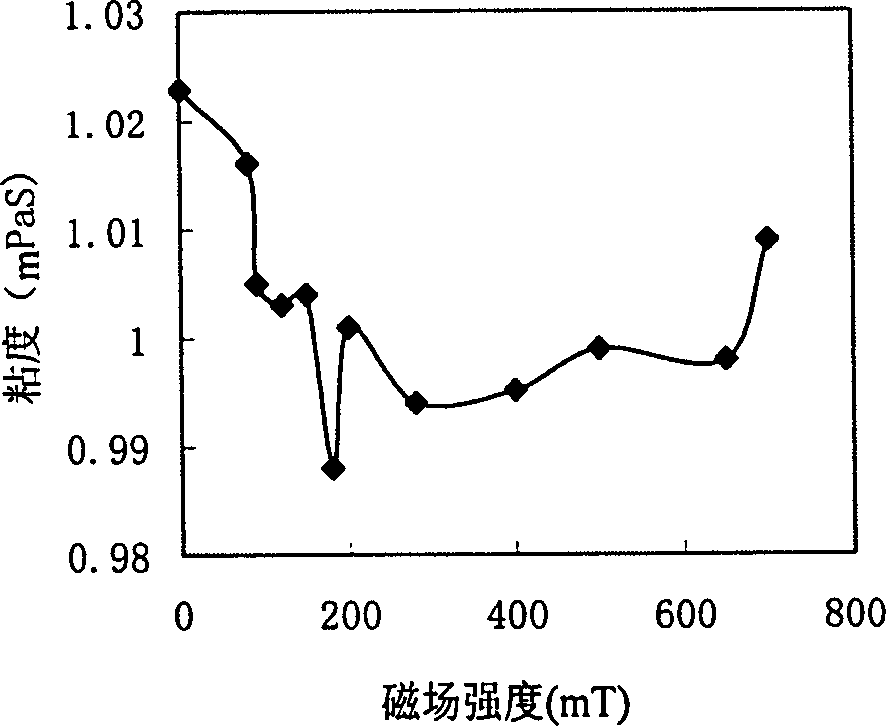

[0036] Example 1: Effect of Magnetization on Viscosity of Water

[0037] Magnetization pretreatment can not only prevent scale, but also affect the viscosity of water. During membrane operation, viscosity is also one of the factors affecting membrane flux [see formula (3)], the lower the viscosity, the higher the flux. It turns out that after magnetization, the viscosity of water will decrease. For example, take high-purity water as a water sample, control the temperature at 25°C, and flow at 1m / S, and pump the water under the conditions of no magnetism (the magnetic field strength is 0) and magnetism (80-700mT, the magnetic field is added to the pipeline). Measure the viscosity of water after circulating for 2 hours, the obtained result is as follows image 3 , where the abscissa represents the magnetic field strength, and the ordinate represents the viscosity. according to image 3 , we can see that the viscosity of water is 1.023mPaS after circulating in the pipeline wi...

Embodiment 2

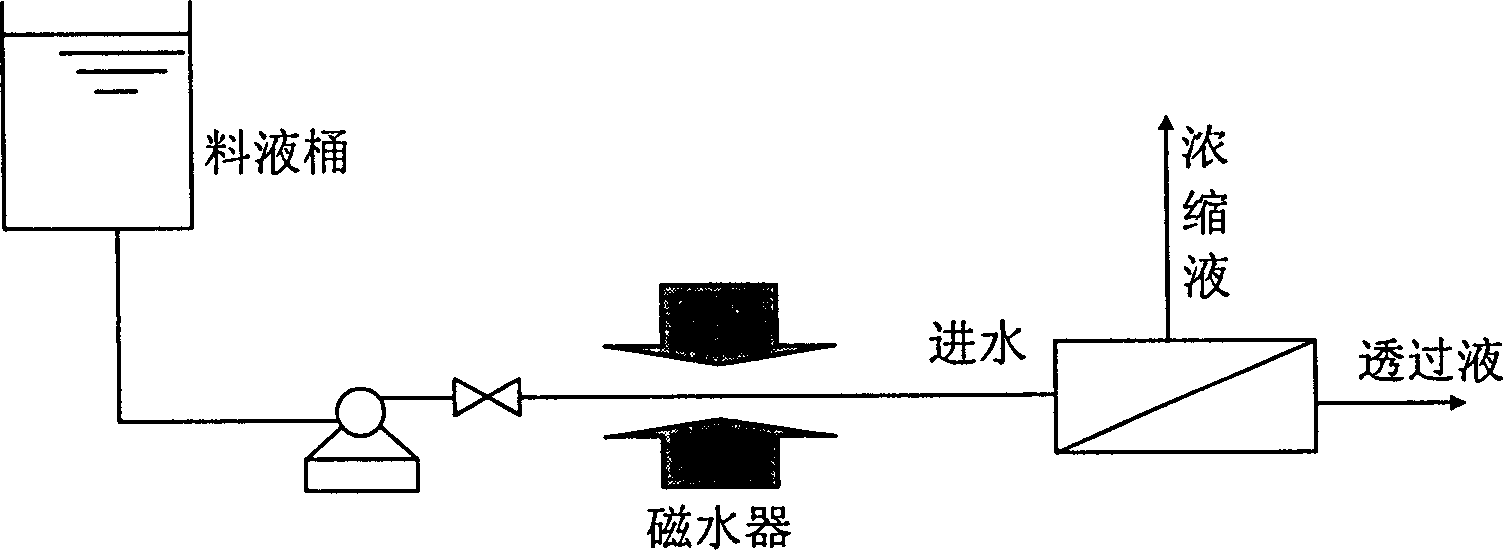

[0038] Example 2: Static nanofiltration and reverse osmosis after split-type magnetization pretreatment

[0039] Calcium Carbonate (CaCO 3 ) is an inorganic substance that is easy to scale on the membrane surface during water softening or water treatment. The formed scale is dense and hard, which hinders the passage of water and increases the operating pressure. Therefore, inhibiting its fouling on the membrane surface will help improve the membrane operating performance and reduce energy consumption. In the process of static nanofiltration and reverse osmosis, the magnetization pretreatment of calcium carbonate is carried out separately from the filtration process, that is, the solution is circulated through the magnetic field pretreatment first, and then filtered. The pretreatment adopts double KC-70C adjustable permanent magnet water magnetizer, and the range of magnetic field strength investigated is 100-800mT. During the filtration, two membranes were used, using nitrog...

Embodiment 3

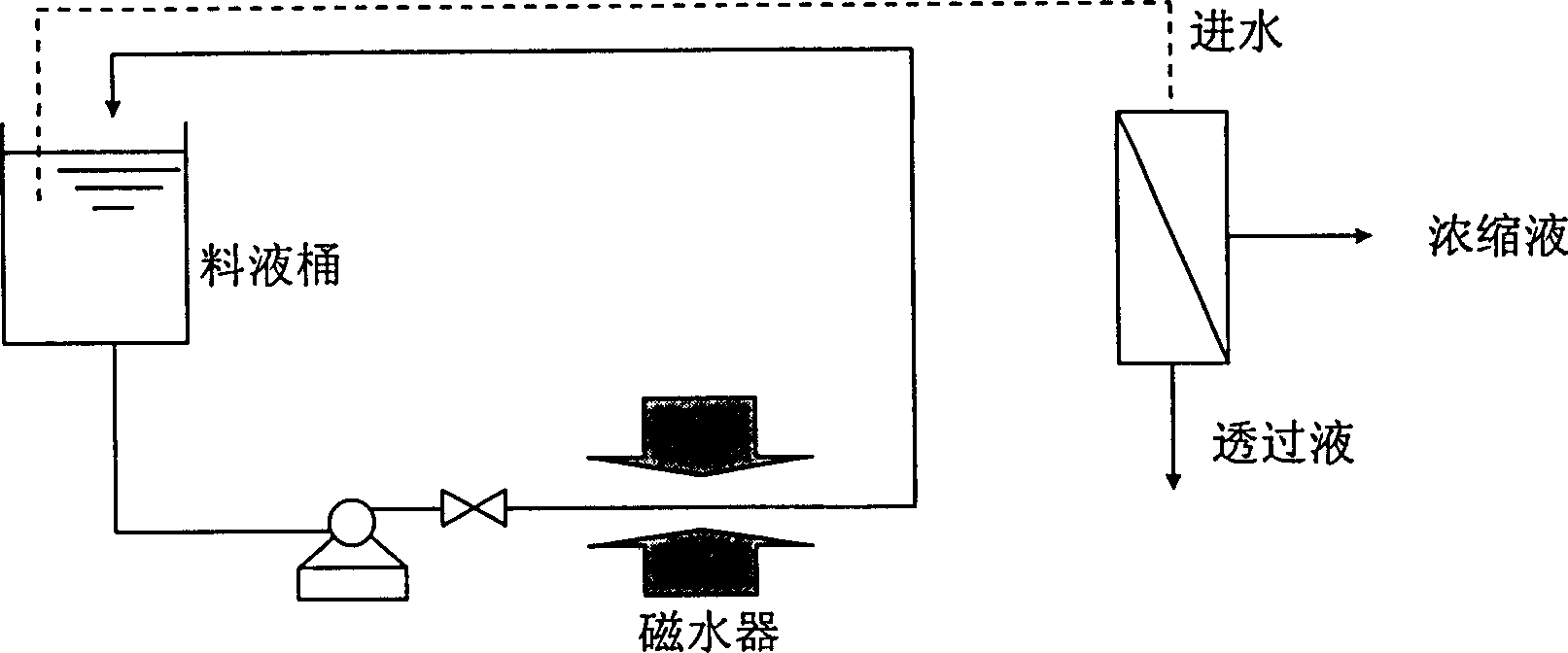

[0041] Example 3: Membrane Process for Integrated Magnetization Pretreatment

[0042] This magnetization pretreatment method is: the solution is transported to the membrane module by a high-pressure pump, and a magnetic water device is placed on the pump outlet pipeline. The magnetic pole gap of the magnetic water device is the channel of the water flow pipeline. The strength of the magnetic field can be adjusted by adjusting the magnetic pole gap. distance is achieved. While performing membrane filtration, the membrane feed water flows through the magnetic field to be magnetized. Under the various conditions of the experimental pressure of 0.5MPa-2.0Mpa, the flow velocity in the magnetic field of 0.5-3m / S, the temperature of 13-40℃, and the pH value of 6.0-8.0, the membrane flux of the magnetized solution is greater than that of the non-magnetized solution. The membrane flux of the solution is high, and the rejection rate of the membrane is high.

[0043] For example, when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com