Granular powder of modified polytetrafluoroethylene

A polytetrafluoroethylene and granular powder technology, which is applied in the field of modified polytetrafluoroethylene granular powder, can solve the problems of low dielectric breakdown voltage, tensile strength of PTFE granular powder and other physical properties of molded products that cannot fully meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

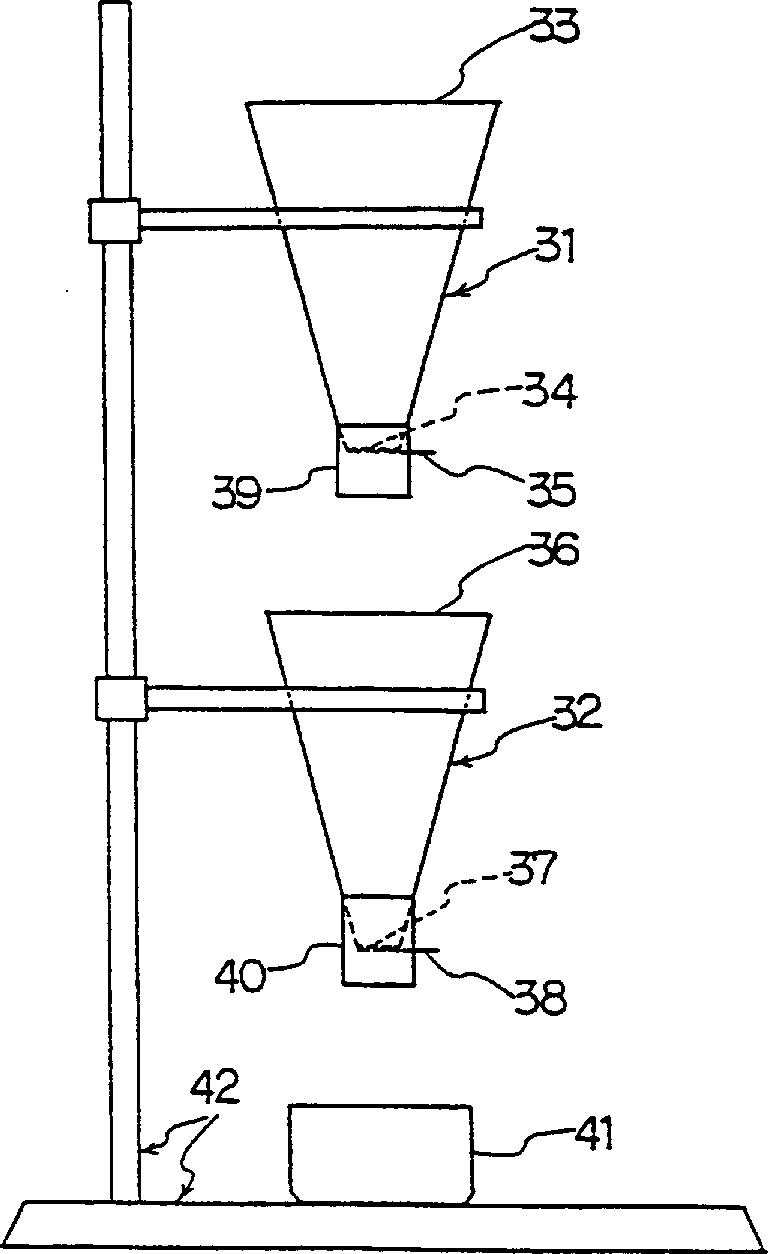

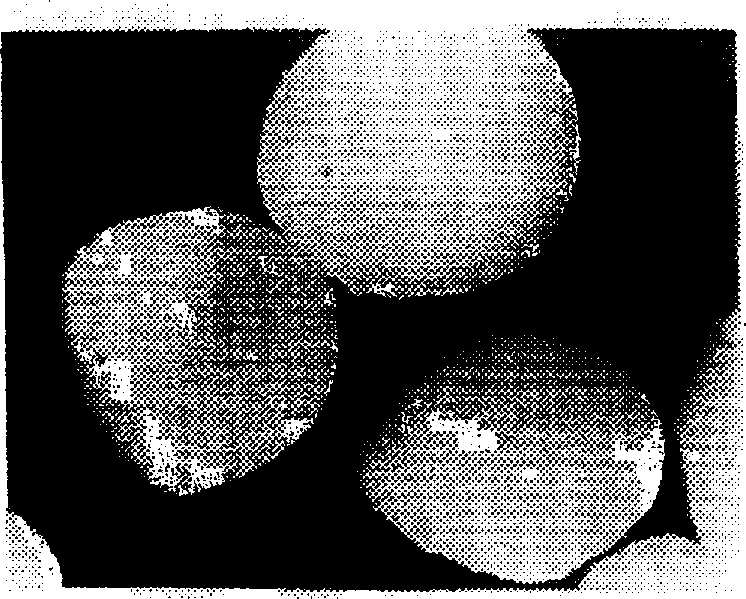

[0158] Put 120-150 liters of ion-exchanged water into a 200-liter granulation tank equipped with conical blades, and adjust the temperature to 20-28°C. The modified PTFE powder (polychlorofluorocarbon (Polyflon) M-111 produced by Daikin Co., Ltd. manufactured by suspension polymerization method) which is pulverized into an average particle diameter of 25 μm was added with 0.1% (mole) perfluoropropylene ethylene Base ether modification) 30kg is packed in the granulation tank. Then, while rotating the conical blade at a rotation speed of 400 rpm, 0.100% of a specific nonionic surfactant (Pronon #104 manufactured by NOF Co., Ltd.) was added. ), add 19.1kg of organic liquid CH after 2-3 minutes 2 Cl 2 . Continue stirring at a speed of 400rpm for 5 minutes to dissolve the organic liquid and PTFE powder, then pass the material in the granulation tank into the pipeline mixer outside the tank, and perform external circulation for 20 minutes. It takes 15 minutes to raise the tempe...

Embodiment 2-10

[0162] Change the amount and type of surfactant in Example 1 and the amount of the organic liquid forming the liquid-liquid interface with water to the amount shown in Table 1, and operate in the same way as Example 1 to obtain the improvement of the present invention Proprietary PTFE granular powder was tested in the same manner as in Example 1, and the results are shown in Table 1.

Embodiment 4

[0163] The nonionic surfactants used in Example 4 are as follows.

[0164] Puronen #208: Manufactured by NOF Co., Ltd.

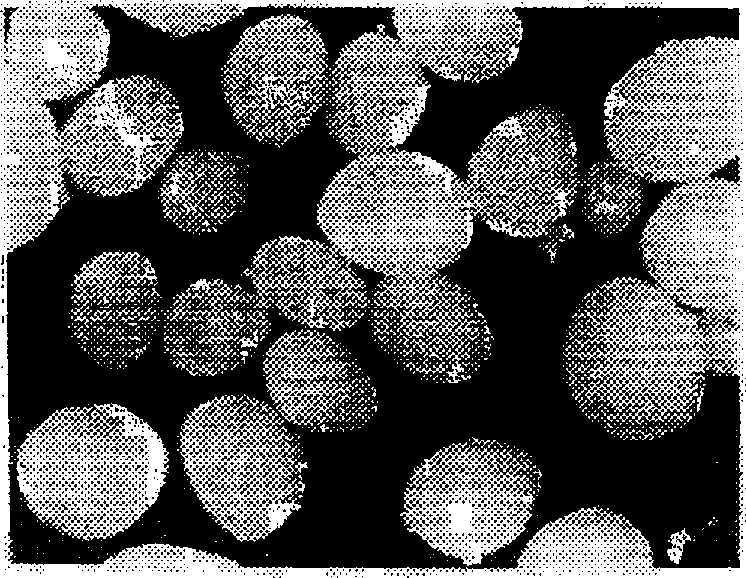

[0165] With regard to the modified PTFE granular powder obtained in Example 3, a photograph of the particles in the powder was carried out in the following manner.

[0166] Particle shape: A photo was taken at 100 times or 200 times magnification using an optical microscope "TV microscope" manufactured by Sony Corporation.

[0167] The results are shown in figure 2 with image 3 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com