Plastic optical fibers, plastic optical fiber cables, optical fiber cables with plugs

A technology of optical fiber and optical fiber, which is applied in the coupling of optical waveguide, optical guide, optics, etc., can solve the problems that the strength of the sheath material cannot be fully improved, the numerical aperture of the optical fiber becomes larger, and the transmission loss of the optical fiber increases. Excellent strength, low bending loss, and low transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

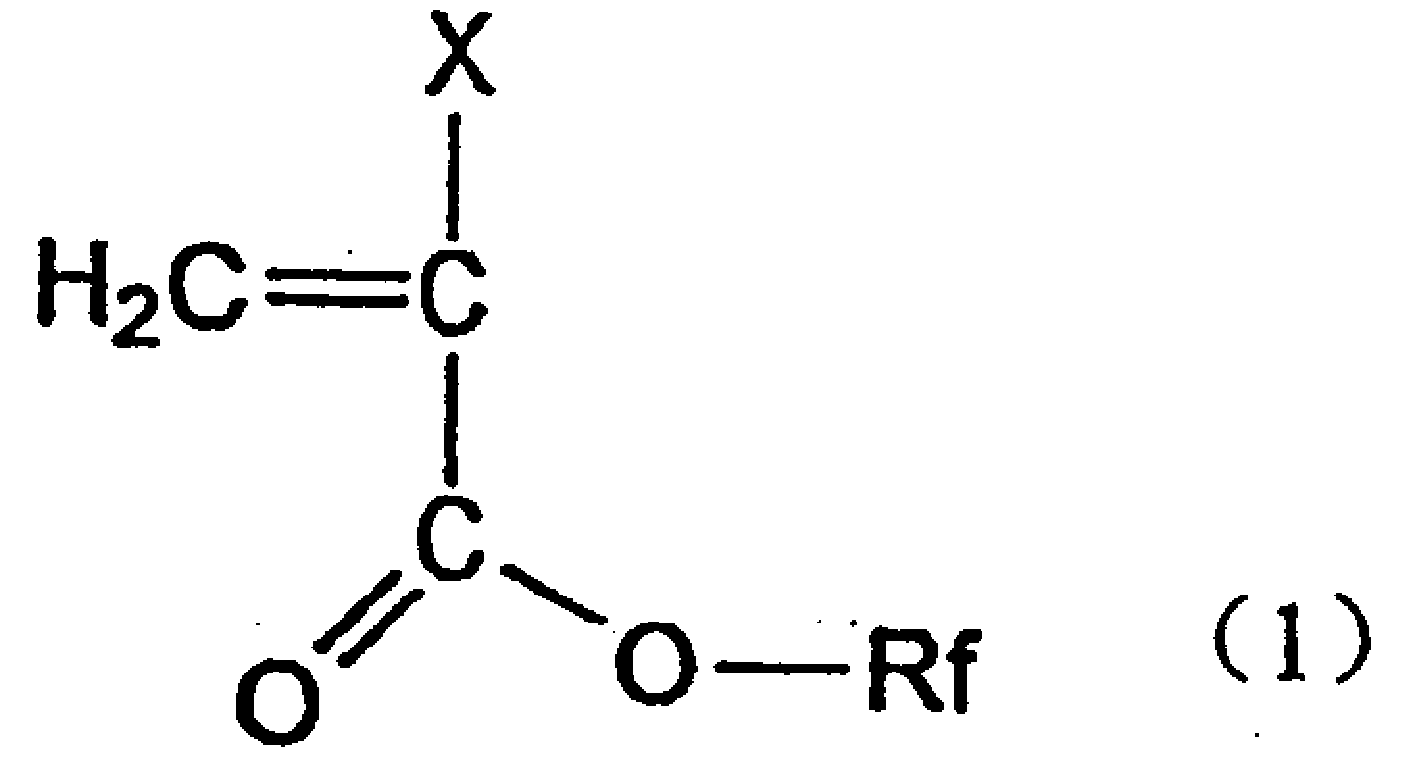

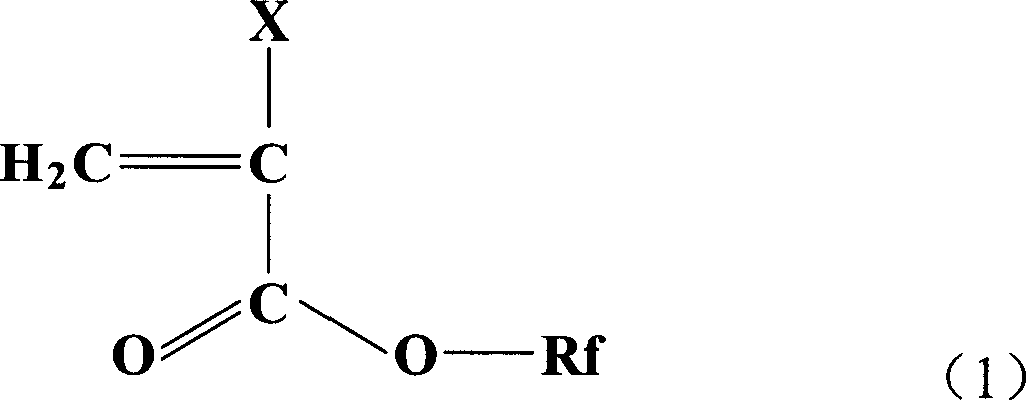

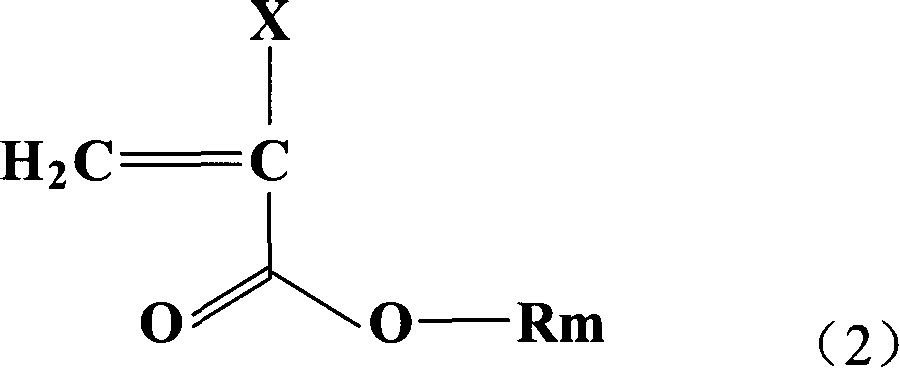

Method used

Image

Examples

Embodiment

[0060] The present invention will be described more specifically by way of examples below. In addition, the evaluation and measurement in an Example were performed by the following method.

[0061] (melt index (MI))

[0062] At 230°C, with a load of 5 kg, the amount of polymer in grams discharged from a die nozzle with a diameter of 2 mm and a length of 8 mm was measured for 10 minutes.

[0063] (refractive index)

[0064] A film-shaped test piece having a thickness of 200 μm was produced by melt extrusion, and the refractive index of the sodium D line was measured at room temperature 25° C. using an Abbe refractometer.

[0065] (Bending test)

[0066] The bending test was carried out according to ASTM D790. A test piece having a length of 5 inches (12.7 cm), a width of 0.5 inches (1.27 cm), and a thickness of 0.25 inches (0.635 cm) was formed using an injection molding machine 75MS manufactured by Mitsubishi Heavy Industries, Ltd. (0.635 cm). Then, using TENSILON / UTM 125...

Embodiment 1

[0084] The composition of the copolymer except for the sheath material is 33% by weight of 2-(perfluorooctyl)ethyl methacrylate, 12% by weight of benzyl methacrylate, 54% by weight of methyl methacrylate, and 1% by weight of methacrylic acid. %, the addition of n-octyl mercaptan is 0.15% by weight, and in the same manner as in Comparative Example 1, a sheath material, an optical fiber, and an optical fiber cable are manufactured, and they are wound on a shaft in the same manner as in Comparative Example 1.

[0085] The melting index of the copolymer for the sheath material is 23 g / 10 minutes, the refractive index is 1.465, and the fracture deflection measured by the bending test is 8.2 mm.

[0086] The transmission loss of this optical fiber is 132dB / km. When this optical fiber was wound on a shaft and heat-treated as in Comparative Example 1, the transmission loss of the heat-treated optical fiber was 195 dB / km, and the increase in transmission loss before and after the heat ...

Embodiment 2~9、 comparative example 2~5

[0088] Except that the copolymer composition of the sheath material was changed as shown in Table 1, the same operation was performed as in Example 1 to manufacture the sheath material, optical fiber, and optical fiber cable. The evaluation results are shown in Table 1.

[0089]

composition

M1

to refract

Rate

deflection at break

Amount (mm)

optical fiber

NA

Loss(dB / km)

fiber optic reel

Transmission loss(dB / km)

fiber optic reel

Loss increase (dB / km)

Teleport when fiber optic cable is reeled

Loss increase (dB / km)

Optical cable transmission frequency

Band (MHz)

Optical cable is bent and broken

Number of cracks

Optical cable bending loss

loss (dB / km)

Example 1

17FM / BzMA / MMA / MAA

33 / 12 / 54 / 1wt%

23

1.465

8.2

0.28

132

195

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com