Transistor vibrator assembly and its mfg. method, and method for mfg. various connected glass plate used for electronic element assembly

A crystal vibrator and manufacturing method technology, applied in the direction of electrical components, power oscillators, impedance networks, etc., can solve the problems of low productivity, difficulty in miniaturization, and inability to adjust, etc., achieve less wiring, reduce working hours, and increase production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

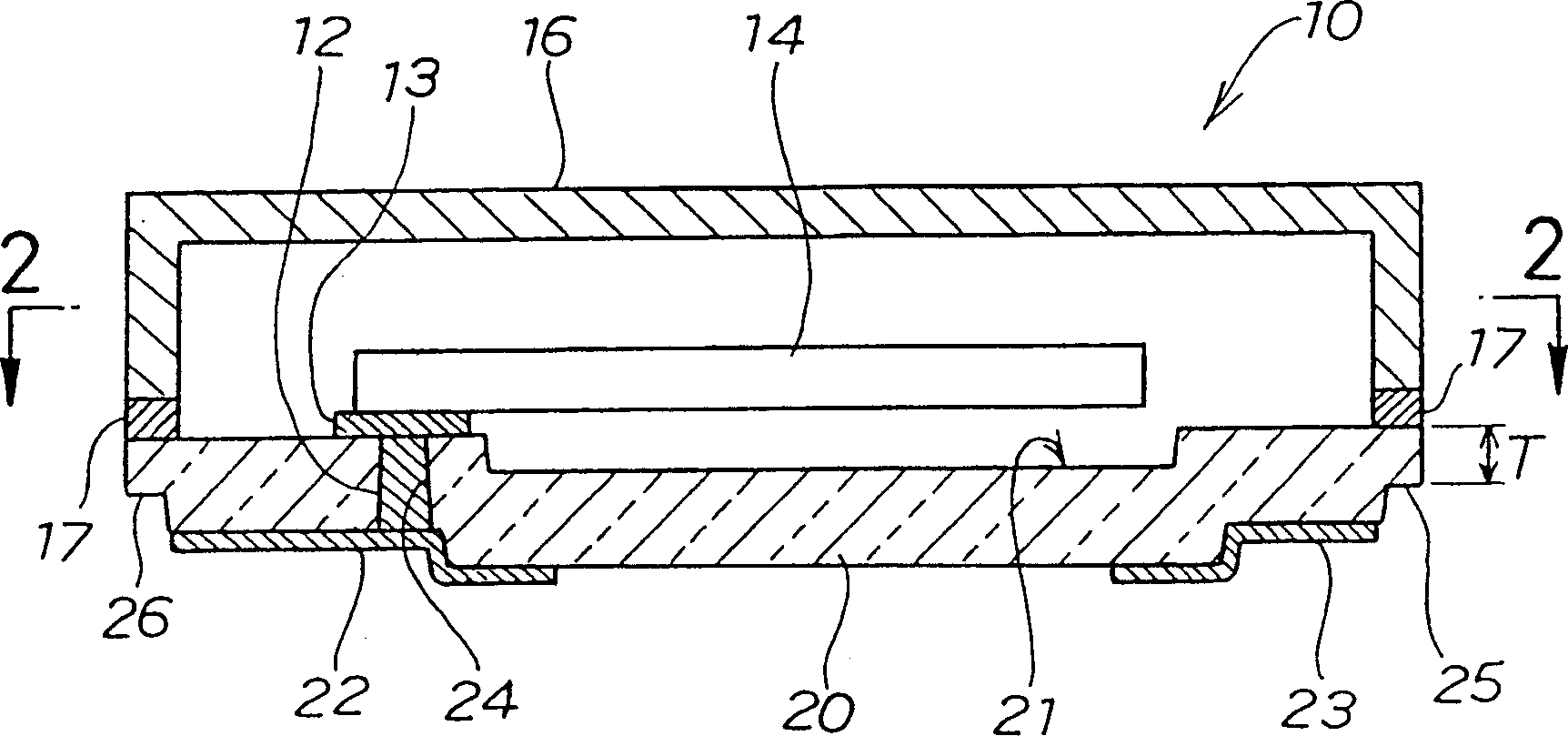

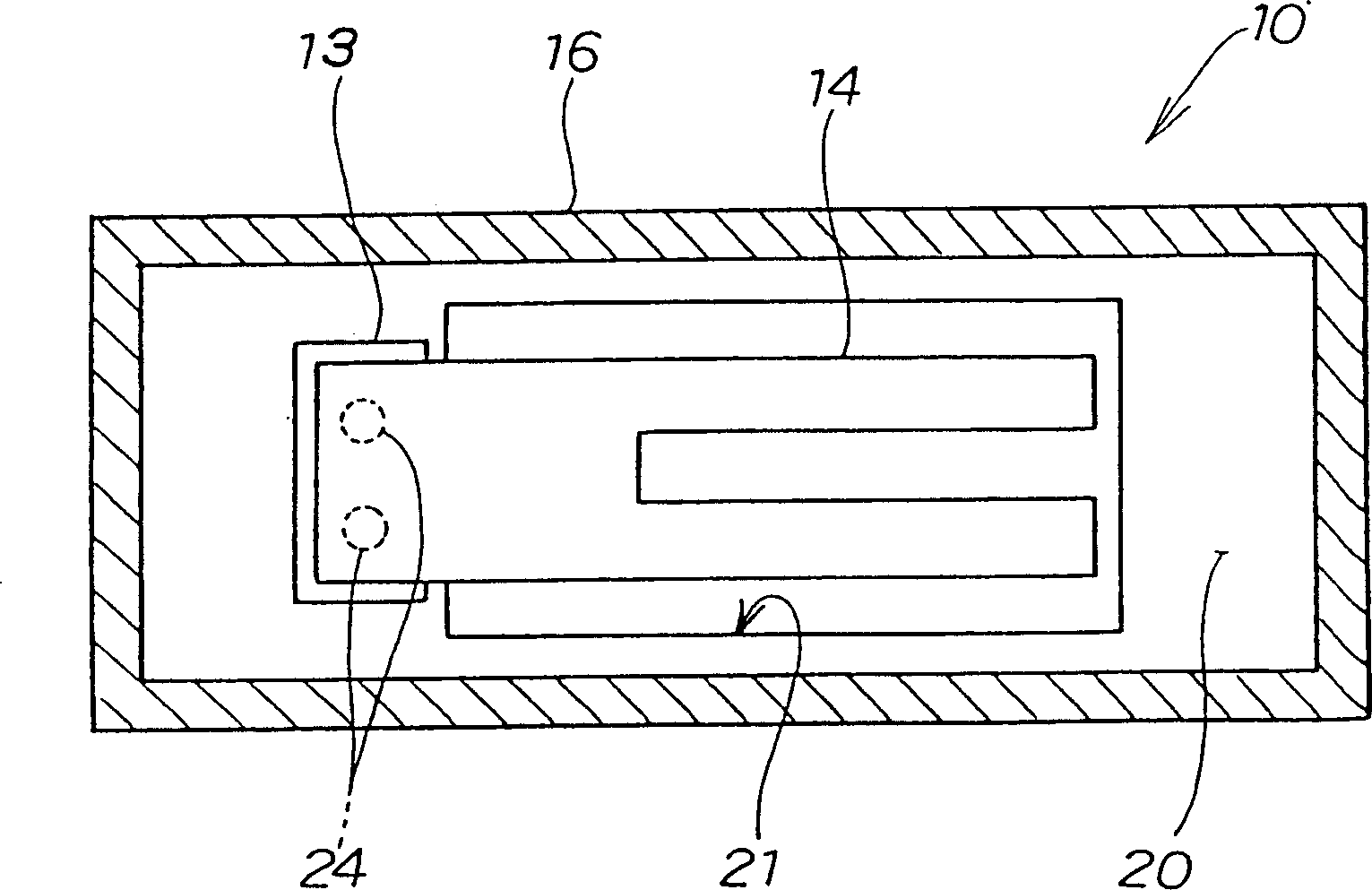

[0075] figure 1 It is a cross-sectional view of the crystal vibrator assembly of the present invention, the crystal oscillator assembly 10 is made of a base 20 made of glass with high transmittance, and the electrode 13 for connecting the crystal on the base 20 is bonded and installed in a cantilever support state The crystal vibrator 14 is composed of a cover 16 for enclosing the crystal vibrator 14 on the base 20 . Among them, 17 is a glass-based adhesive. In order to improve the adhesive force, the edge of the base 20 on which the glass-based adhesive 17 is applied should be processed so that the surface roughness is 3-4 μm. Grinding with alumina abrasives can easily form the above-mentioned rough surface.

[0076] The cover 16 can be made of opaque materials such as metal, but in order to adjust the frequency of the internal crystal oscillator, the laser beam must pass through the base to irradiate the crystal oscillator. Therefore, in order to fully transmit the laser be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com