Controllable container type complete equipment for anaerobic fermentation and methane liquid treatment

A biogas slurry treatment and anaerobic fermentation technology, applied in biological sludge treatment, energy wastewater treatment, waste fuel, etc., can solve the problems of long investment recovery period, small gas production, complex structure technical requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

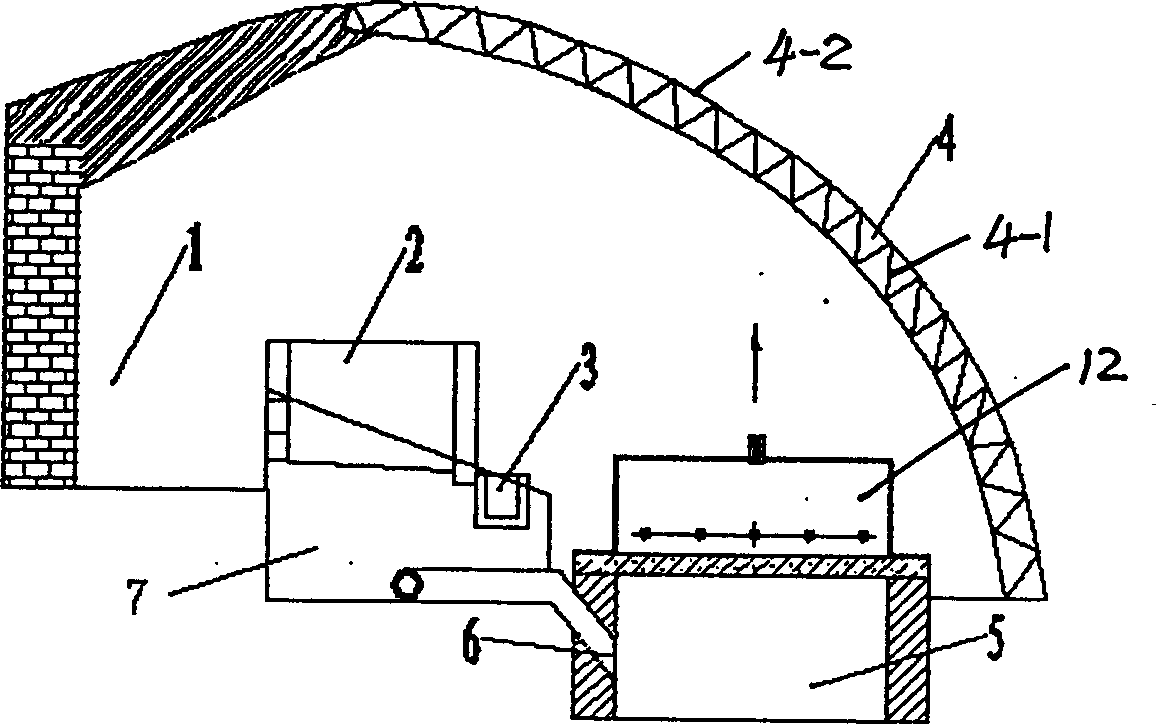

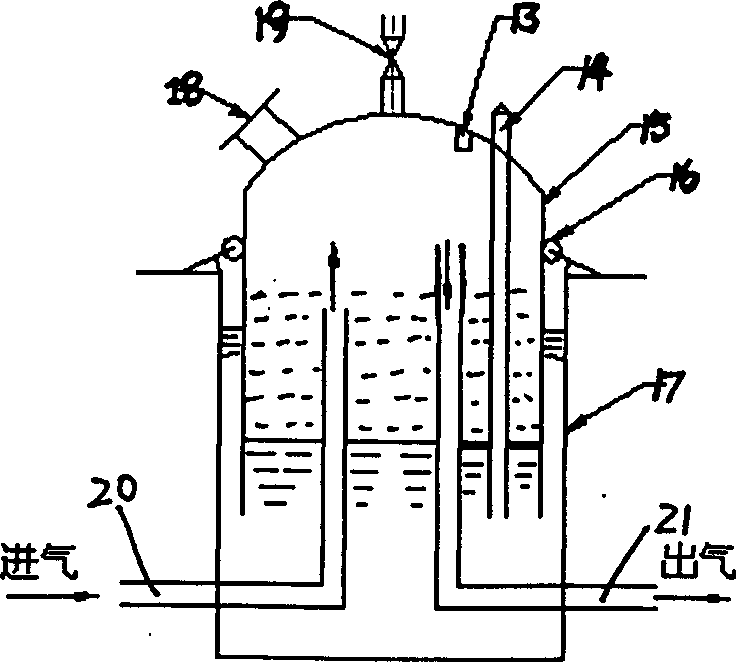

[0022] Composition of controllable header anaerobic fermentation system

[0023] 1. Basic composition of biogas fermentation system

[0024] The biogas fermentation system is mainly composed of sidewalk 1, pigsty 2, excrement trough 3, feed inlet 6, discharge outlet 9, heating pipeline 10, solar heating greenhouse 4, biogas fermentation tank 5, auxiliary heating equipment 11, preheating Fermentation tank 7, several parts such as steel biogas fermentation tank loam cake 12 are formed. (Such as figure 1 , figure 2 shown)

[0025] (1) Feed port

[0026] The upper edge of the lower opening of the feed pipe is located at 1 / 3 to 1 / 2 of the biogas tank body, and the angle with the wall of the biogas tank is generally about 30°. The aperture of feeding port 6 is determined as 800 * 800.

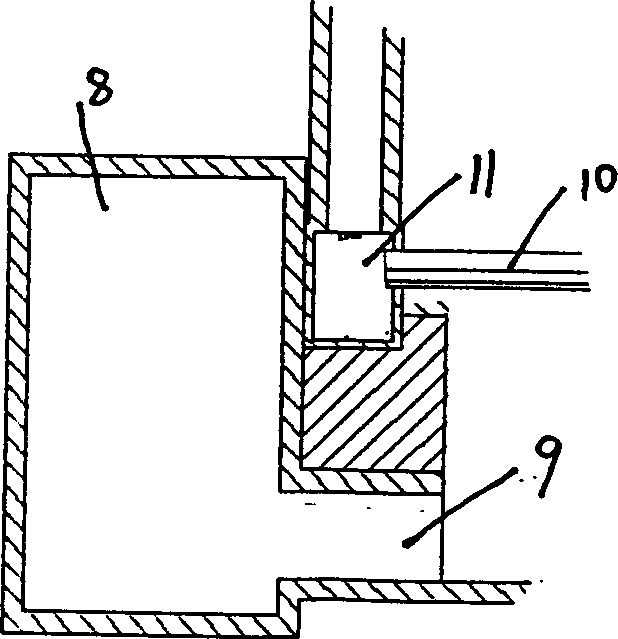

[0027] (2) Design of outlet and water pressure room

[0028] Discharge room 8: the discharge port 9 pipeline is opened below the flue gas chamber (such as figure 2 shown), the aperture size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com