Two-phase dry anaerobic digestion fermentation system

A fermentation system, dry anaerobic technology, applied in the field of two-phase coherent anaerobic digestion and fermentation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

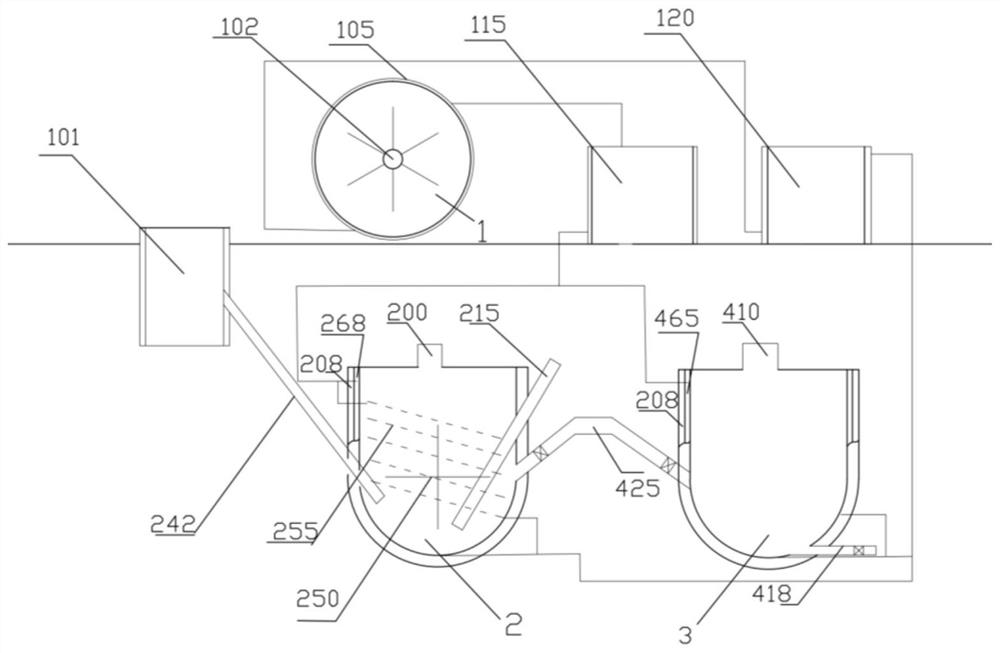

[0099] as attached figure 1 As shown, a two-phase anaerobic digestion and fermentation system provided for an embodiment of the present invention, the two-phase anaerobic digestion and fermentation system includes:

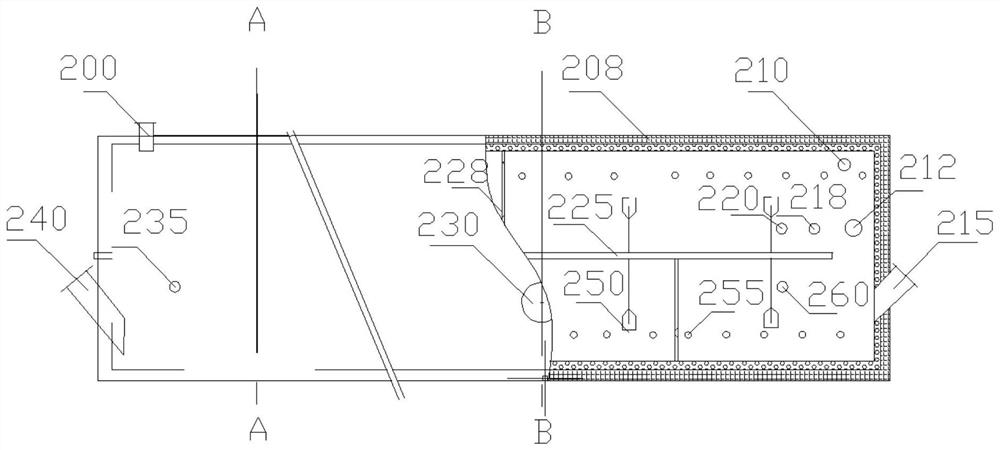

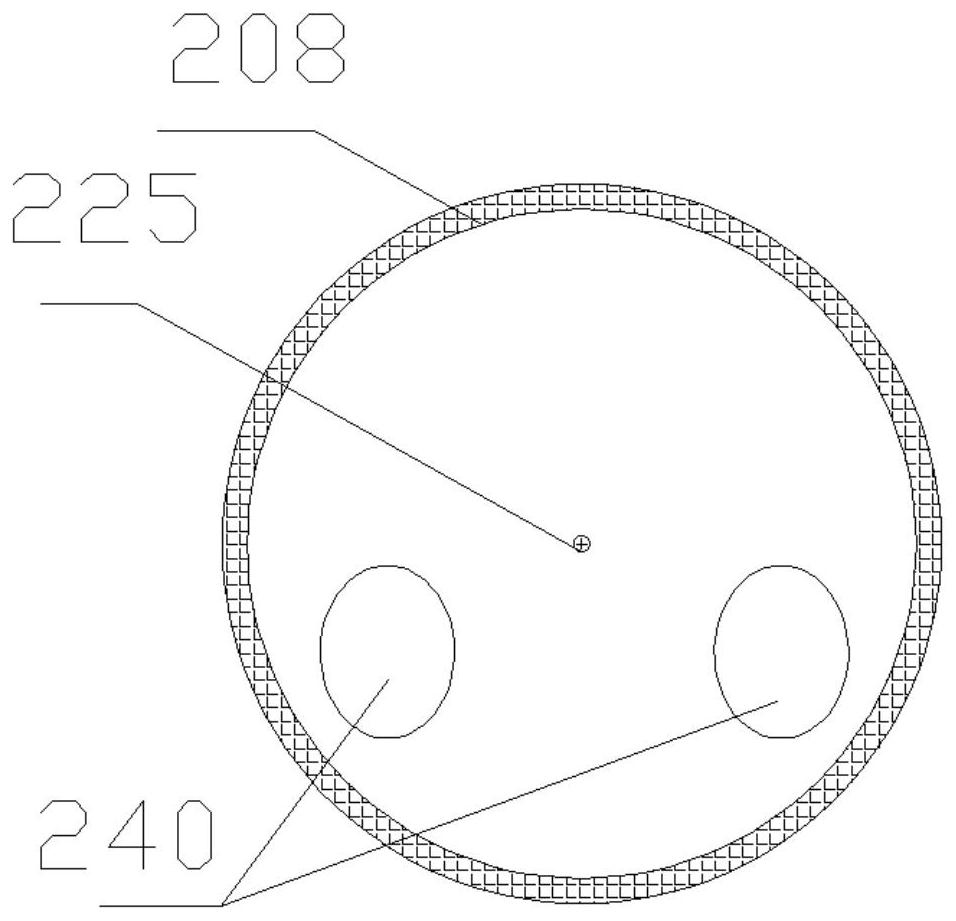

[0100] A hydrolytic acidification pool 2; the hydrolytic acidification pool 2 has hydrolytic acidification bacteria, which are used to hydrolyze and acidify materials;

[0101] Methanation pool 3; there are methanogenic bacteria in the methanation pool 3; the methanation pool 3 is connected with the hydrolytic acidification pool 2, and the digested raw materials after hydrolysis and acidification automatically flow into the methanation pool 3 by their own weight and pressure difference, and are Methanogenic bacteria decompose into biogas slurry, biogas residue and biogas;

[0102] The composting reactor 1 is used for composting the mixture of biogas residue and biogas slurry produced in the methanation tank 3 and specified raw materials, and the heat energy gener...

Embodiment 2

[0201] In this embodiment, the two-phase anaerobic digestion and fermentation system in Example 1 is used for actual fermentation, and the fermentation process is as follows:

[0202] The residual heat generated by the composting raw materials reacting in the composting reactor 1 heats the medium (water) to 60-65°C through the heat exchanger 102, flows into the first medium circulation container 115, and passes through the first jacket 268 and the first jacket 268 of the hydrolysis acidification tank 2. After exchanging heat between the heat exchange coil 255 and the second jacket 465 of the methanation tank 3 , it is sent back into the second medium circulation container 120 , and finally pumped into the heat exchanger 102 of the composting reactor 1 for heating.

[0203] After the kitchen waste and agricultural straw are preliminarily crushed, they are sent to the feeding container 101 with the breeding manure at a ratio of 1:1:1, and a certain amount of biogas slurry dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com