Film processing method and film processing system

A technology for thin film treatment and treated objects, which is applied in the field of thin film treatment methods and thin film treatment systems, and can solve the problems that ultraviolet light is difficult to penetrate into the film and cannot remove charges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, according to Figure 1 to Figure 8 The illustrated embodiments illustrate the invention.

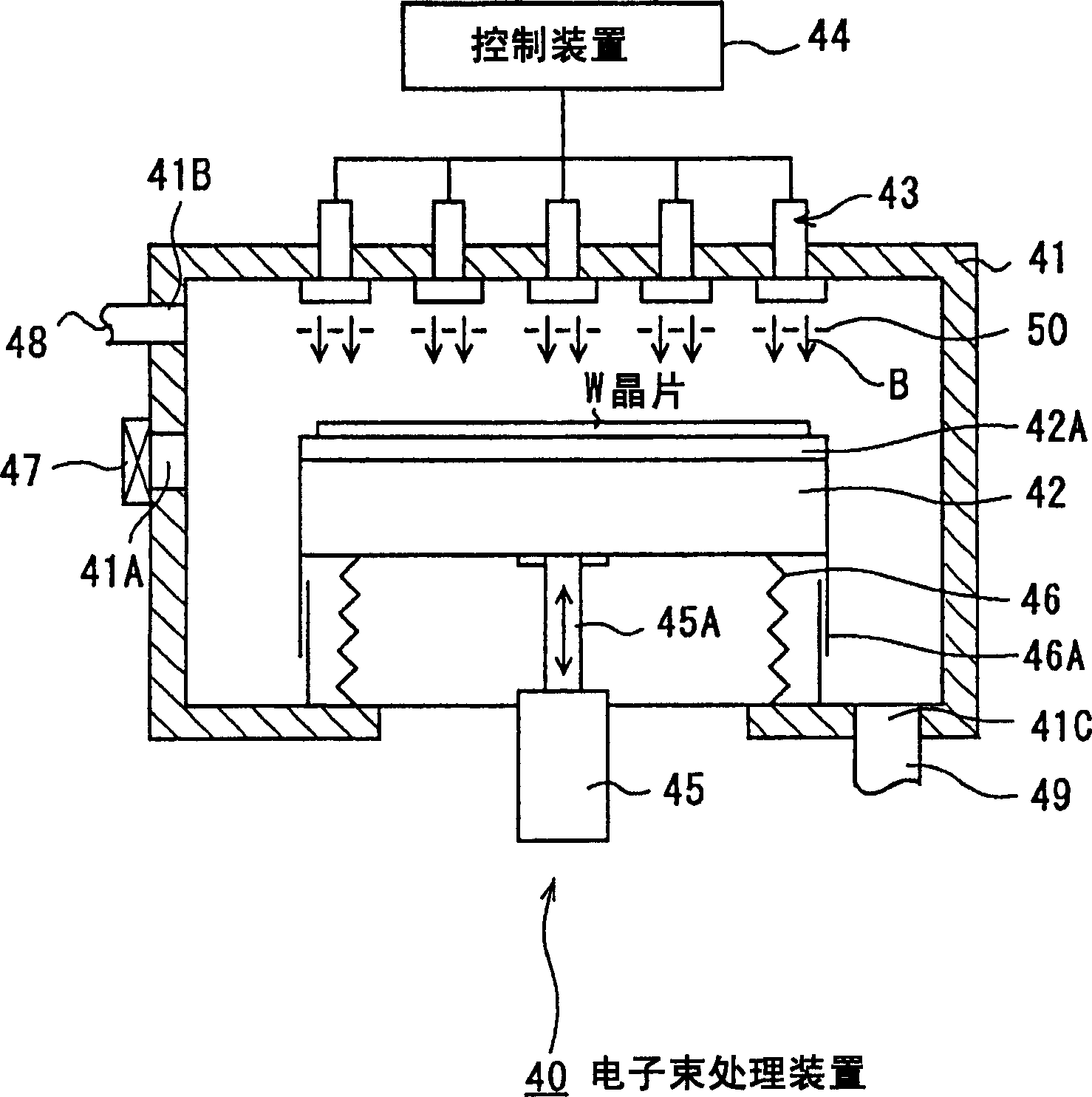

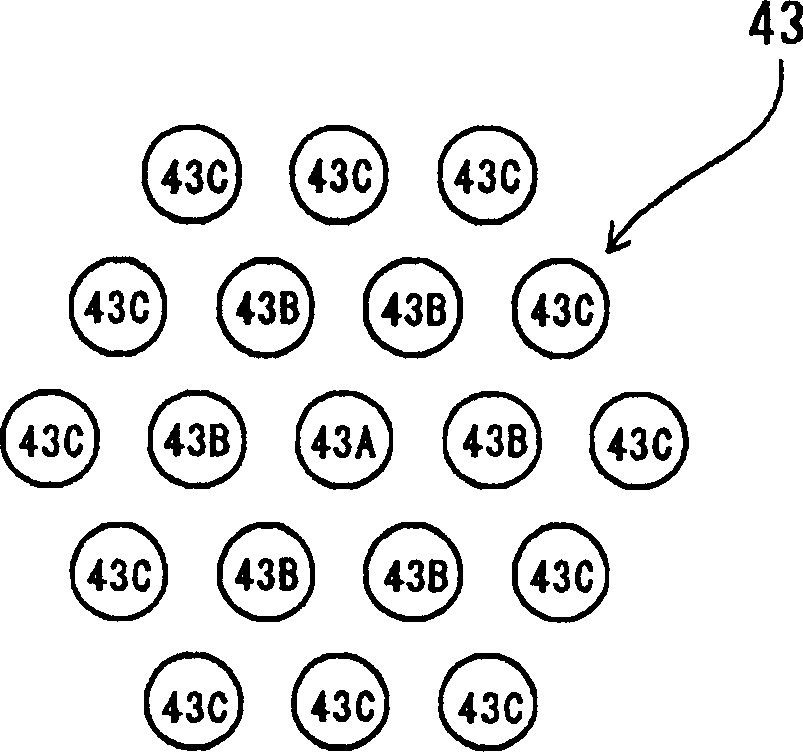

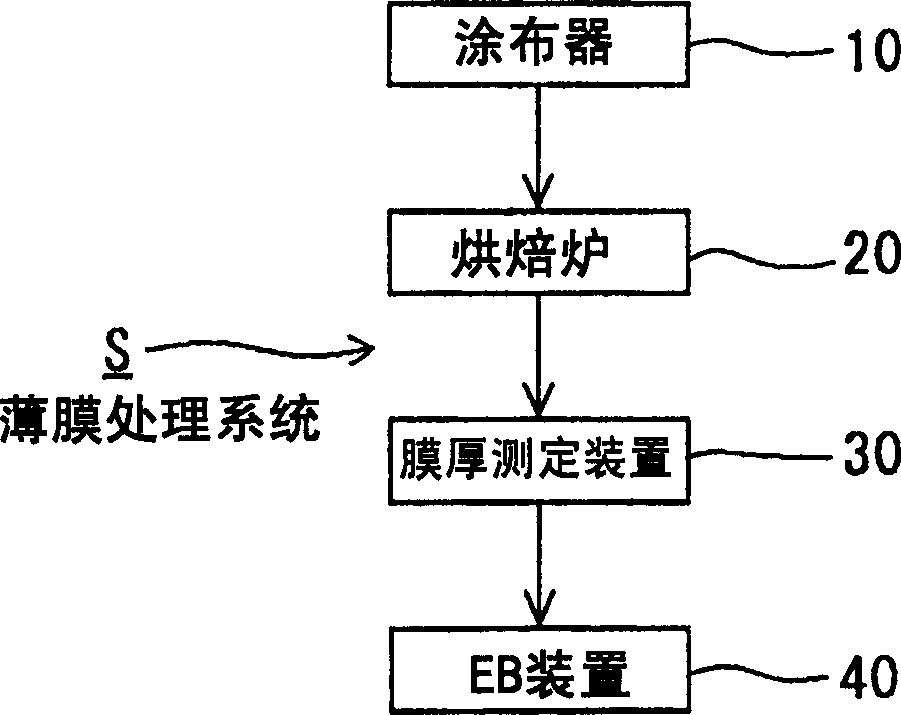

[0036] For example, if image 3 As shown, the thin film processing system S of the present embodiment includes: a spin coating device (spin coater) 10 for coating an SOD film material on the surface of an object to be processed (for example, a wafer); The downstream side of the device 10 and the baking furnace 20 that heat-treats the SOD film formed on the wafer; The film thickness measuring device 30 that is configured on the downstream side of the baking furnace 20 and measures the film thickness of the SOD film after heat treatment; On the downstream side of the thickness measuring device 30 , an electron beam processing device (EB device) 40 that irradiates an electron beam onto the SOD film based on the measurement result of the film thickness measuring device 30 . As the spin coater 10, the baking oven 20, and the film thickness measuring device 30 used at this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com