Face smearing mortar for self temperature regulation building wall and its preparing method

A technology for building walls and plastering mortar, which is applied to heat exchange materials, chemical instruments and methods, etc., can solve the problems of unstable performance of phase-change working materials, no antibacterial and anti-mildew functions, and affecting temperature adjustment functions. To achieve the effect of preventing cross infection, facilitating promotion and living comfortably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 40Kg of construction sand, 40Kg of ordinary cement, 5Kg of rare earth-activated inorganic antibacterial agent, and 18Kg of water into the concrete mixer and mix them thoroughly, then add 15Kg of phase change composite materials; stir fully for 2 minutes, mix well and use directly.

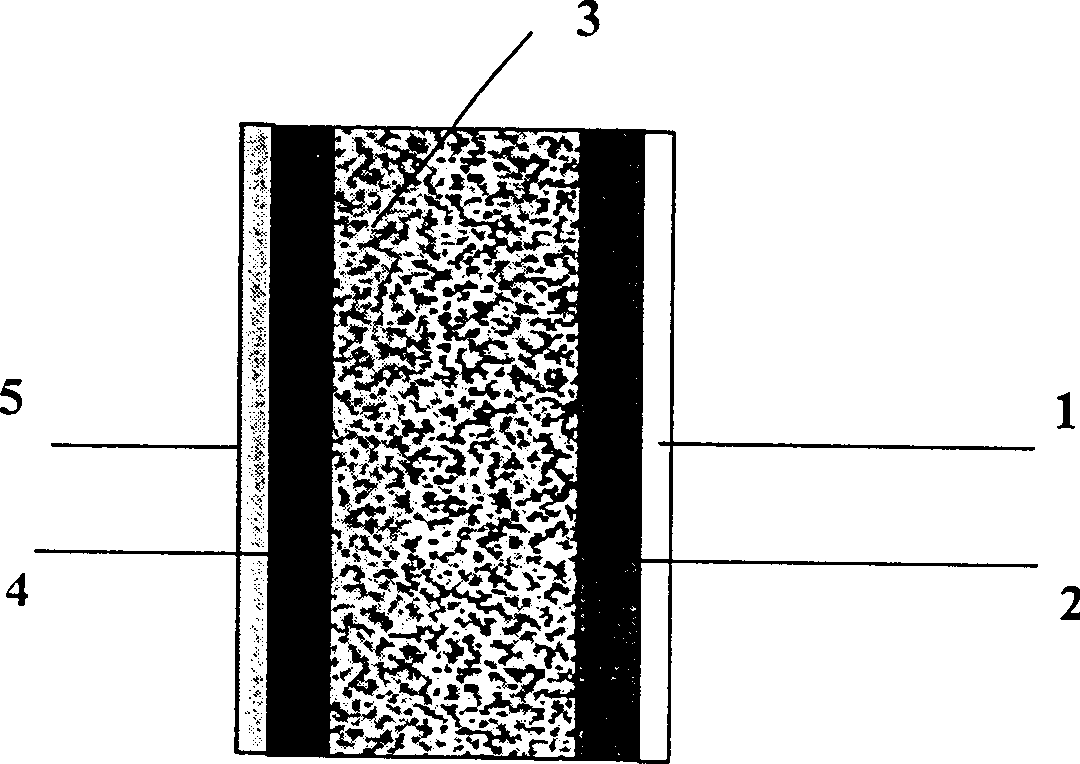

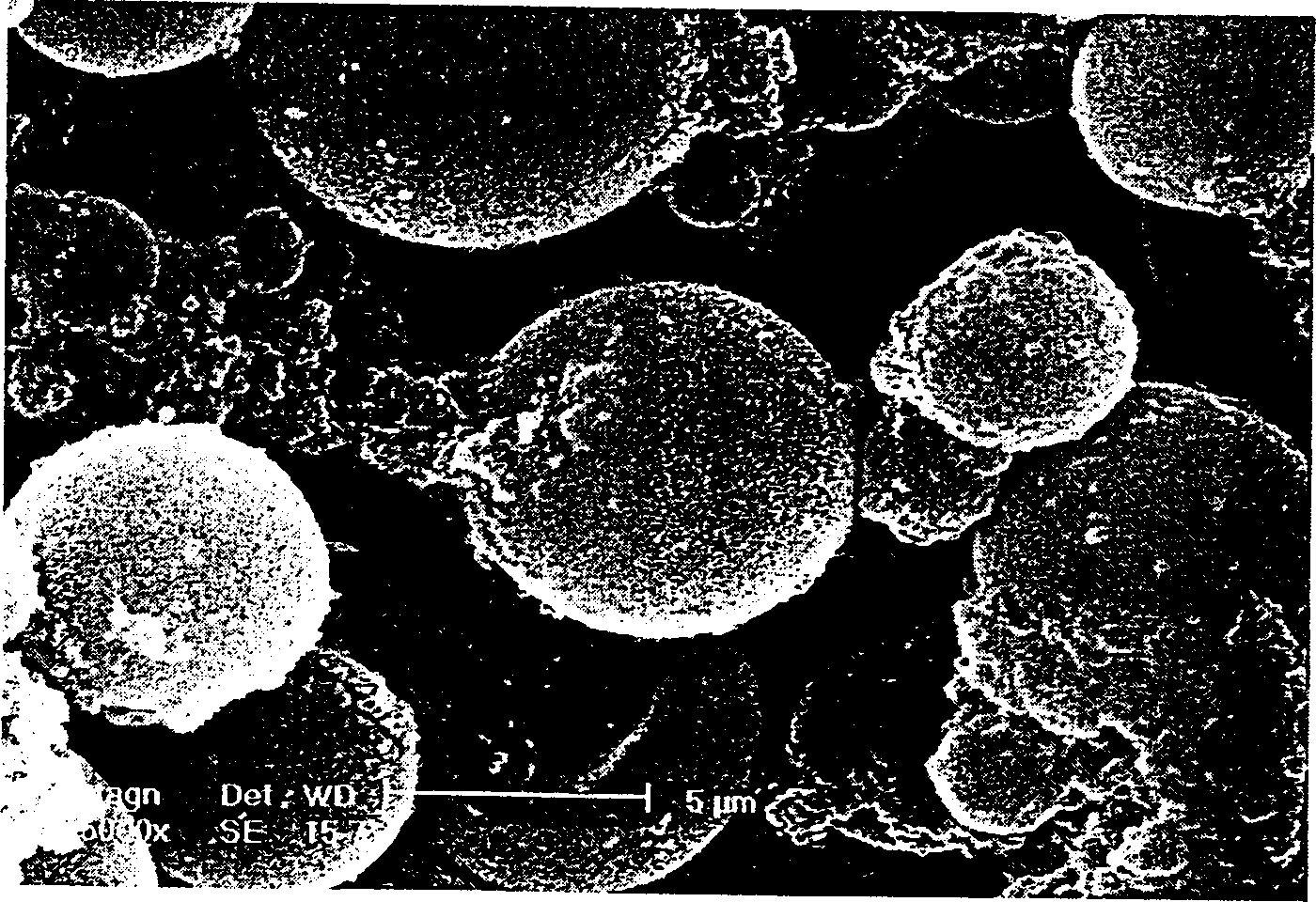

[0031] Wherein the phase-change composite material is composed of microcapsules containing phase-change working fluid materials, wherein the phase-change working fluid materials are composed of microcapsules containing 50% octadecane capsule core and 50% melamine-formaldehyde resin capsule wall; The shape of the composite material is as figure 2 The scanning electron microscope photographs are shown.

[0032] The mortar is used in building construction and has a good self-regulating function. After testing, the wall mortar plastering material added with phase-change working fluid materials will not produce macroscopic exudation and hoarfrost within 30 years of use; The fluctuation rang...

Embodiment 2

[0034]Put 50Kg of cement, 35Kg of construction sand, 5Kg of silver zeolite inorganic antibacterial agent, and 25Kg of water into the concrete mixer and mix them thoroughly, then add 10Kg of phase-change self-regulating composite material, and stir for 2 minutes to make self-regulating functional building cement mortar . Wherein the phase change composite material used is to add the microcapsule of weight percent 50% octadecane capsule core and 50% melamine-formaldehyde resin capsule wall, and the appearance of its microcapsule is as follows figure 2 The scanning electron microscope photographs are shown.

[0035] Its technical effect is the same as embodiment one.

Embodiment 3

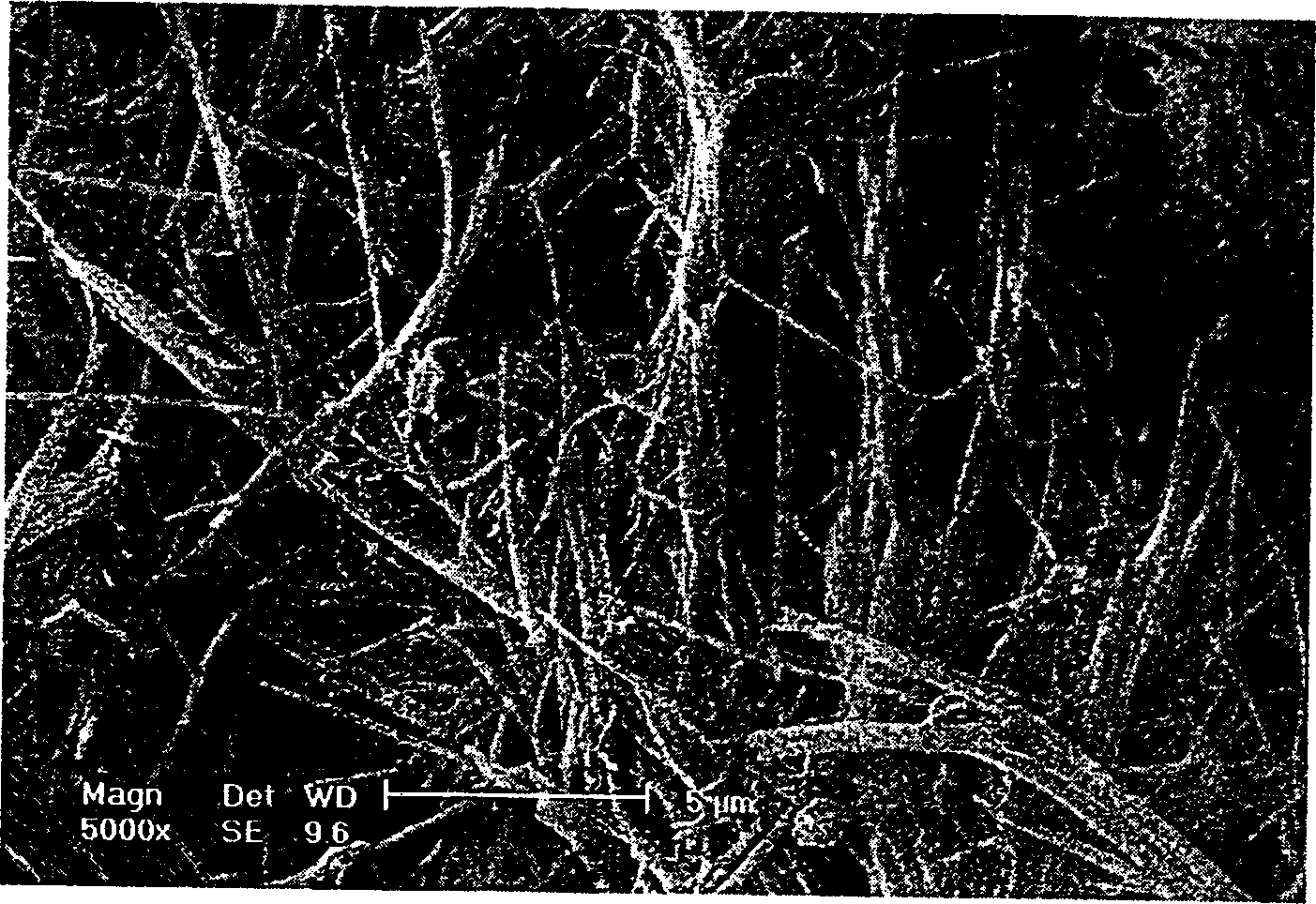

[0037] Mix 40Kg of quicklime powder, 54Kg of construction sand, 1Kg of rare earth-activated inorganic antibacterial agent, and 20Kg of water, then put them directly into a concrete mixer and mix thoroughly, then add 5Kg of phase-change self-regulating unit particles, and after stirring for 2 minutes, the self- Temperature-regulating functional building mortar. Wherein the phase-change self-regulating temperature unit particles contain 60% by weight of dodecyl alcohol and 40% by weight of sepiolite, and the morphology of the phase-change self-temperature-regulating unit particles is as follows image 3 As shown in the scanning electron microscope photo, the phase transition temperature of the phase transition working fluid material is 24.0°C.

[0038] Its technical effect is the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com