Method for preparing ten nanometers level solid lipid nanometer particle

A solid lipid nanometer and nanometer technology, which is applied in the methods of granulating raw materials, liposome delivery, chemical instruments and methods, etc., can solve problems such as large size, achieve high repeatability, convenient transportation, storage and use, Simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

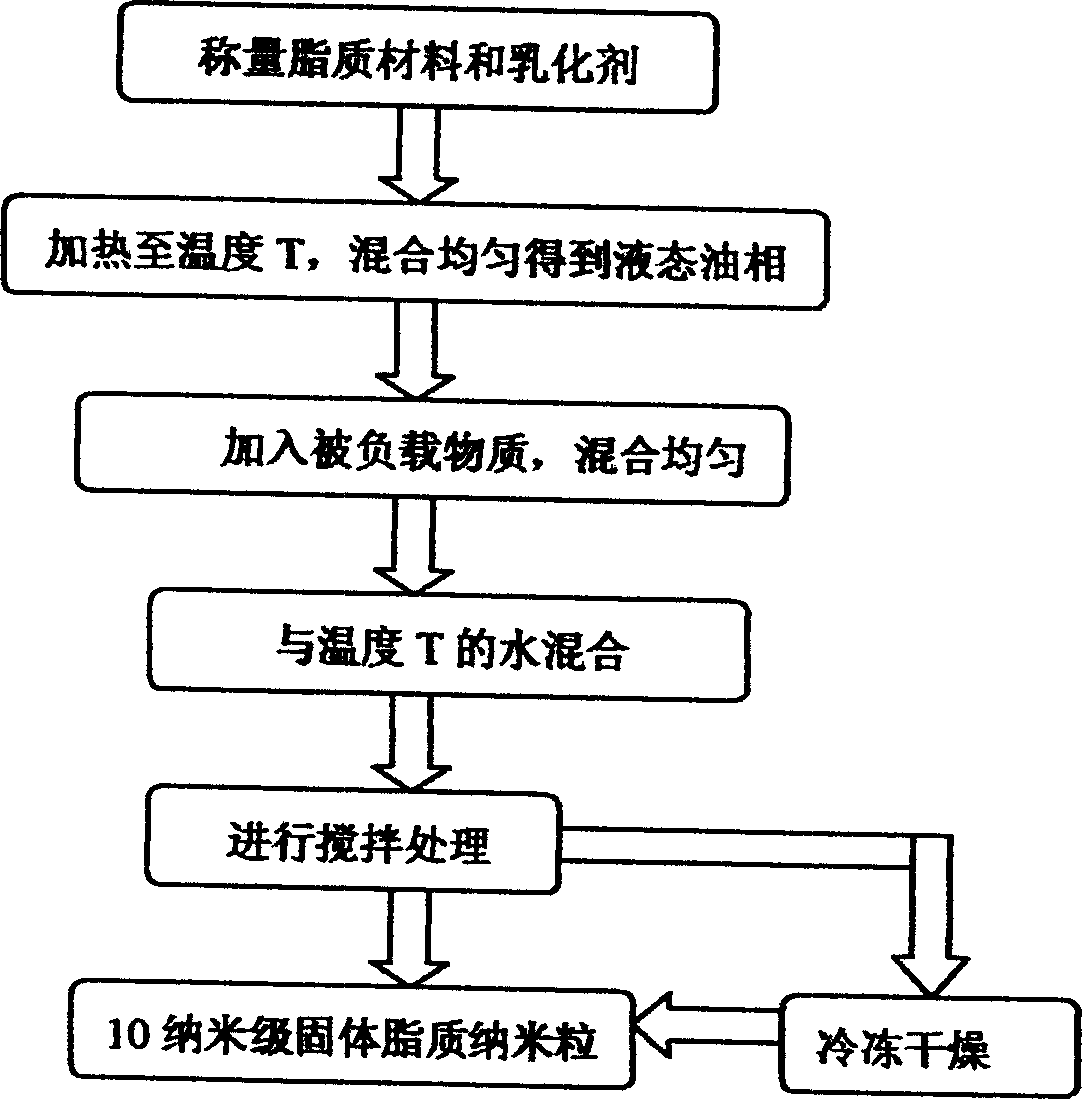

[0023] The preparation method of ten nanometer order solid lipid nanoparticles of the present invention is:

[0024] a, weigh lipid material and emulsifier respectively, the mass ratio of the two, i.e. lipid material: emulsifier is 1: 4~1: 6; after mixing lipid material and emulsifier, heat to set temperature T, That is, T=60-80 degrees Celsius, and the liquid oil phase is obtained after melting; wherein, the lipid material is glyceryl monostearate, and the emulsifier is polyoxyl stearate S-40 and poloxamer F-68 according to 7:3 mixture,

[0025] b. Weigh the substance loaded by the lipid material as the carrier, the mass ratio of the substance to the lipid material is 1: 10 to 1: 200, add the substance into the liquid oil phase, stir to dissolve the substance completely, and obtain clarification system;

[0026] c. Add water at the same temperature as the set temperature T to the above-mentioned clarification system. The quality of the water is 20 to 200 times that of the l...

Embodiment 1

[0033] 1. Weigh 2.1 grams of polyoxyl stearate S-40, 0.9 grams of poloxamer F-68, and 0.5 grams of glyceryl monostearate, and put them into the sample tube;

[0034] 2. Heating in a water bath at 60°C to make it completely melted and then adding 20 mg of vitamin E to obtain a clarified system;

[0035] 3. Add 24 ml of distilled water at 60°C to the above clarification system;

[0036] 4. Stir for 10 minutes;

[0037] 5. Decrease to room temperature to obtain ten nanometer solid lipid nanoparticle dispersion.

[0038] 6. Freeze-drying to obtain vitamin E solid lipid nanoparticles of ten nanometer scale.

Embodiment 2

[0040] 1. Weigh 2.1 grams of polyoxyl stearate S-40, 0.9 grams of poloxamer F-68, and 0.5 grams of glyceryl monostearate, and put them into the sample tube;

[0041] Heating in a water bath at 2.75°C to make it completely melted and then adding 5 mg of azelaic acid to obtain a clarified system;

[0042] 3. Add 24 ml of distilled water at 75°C to the above clarification system;

[0043] 4. Stir for 20 minutes;

[0044] 5. Decrease to room temperature to obtain ten nanometer solid lipid nanoparticle dispersion.

[0045] 6. Freeze-drying to obtain ten nanometer-sized azelaic acid solid lipid nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com