Treating method and micro flocculation reactor for reusing washing sewage

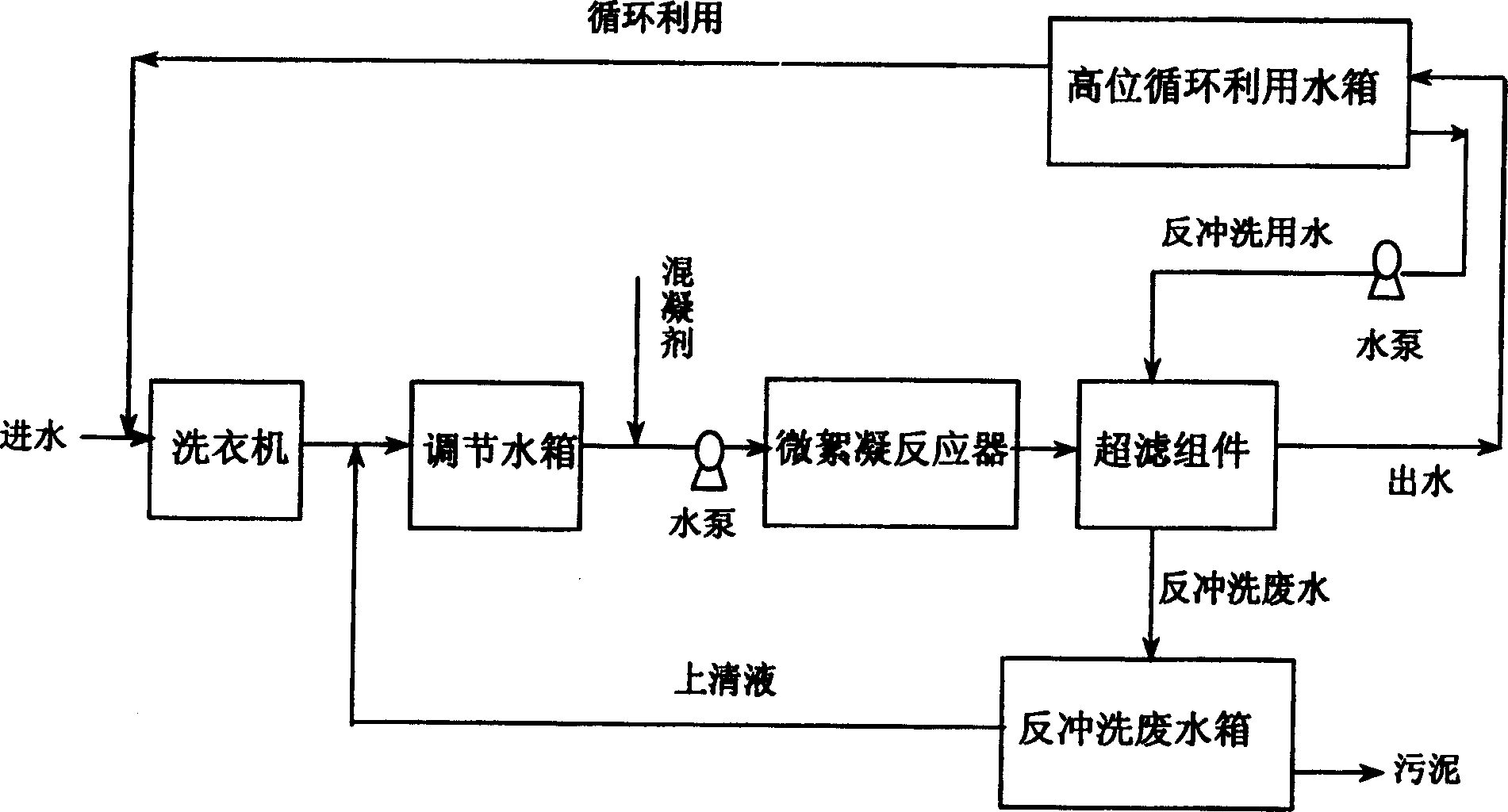

A treatment method and technology of sewage circulation, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve complex process, low water recovery rate, sludge Large volume and other problems, to achieve the effect of saving water resources, high recovery rate, less sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: The treated water volume is 1m 3 / h: Collect the washing sewage discharged from the washing machine into the regulating water tank, and use the filter installed in the regulating water tank to intercept the lint and other sundries in the washing sewage; add the coagulation agent to the suction port of the water pump in front of the micro-flocculation reactor After the polyaluminum chloride 40mg / L, it enters the microflocculation reactor to react for 25s, so that the fine suspended solids, organic matter, grease, etc. in the water form microflocs; after microflocculation, it is filtered through an ultrafiltration membrane with a molecular weight cut-off of 100,000Da The polypropylene PP hollow fiber membrane, under the membrane pressure of 0.1MPa, the microflocs and bacteria in the water are almost completely intercepted by the surface of the membrane, 75% of the free anionic surfactant in the water penetrates the membrane pores, and the filtered The water is conn...

Embodiment 2

[0021] Example 2: The treated water volume is 5m 3 / h: Collect the washing sewage discharged from the washing machine into the regulating water tank, and use the filter installed in the regulating water tank to intercept the lint and other sundries in the washing sewage; add the coagulation agent to the suction port of the water pump in front of the micro-flocculation reactor After aluminum sulfate 80mg / L, it enters the micro-flocculation reactor to react for 15s to make small suspended solids, organic matter, grease, etc. in the water form micro-flocs; after micro-flocculation, it is filtered through an ultrafiltration membrane, which uses a polymer with a molecular weight cut-off of 50,000 Da Acrylonitrile PAN hollow fiber membrane, under the membrane pressure of 0.15MPa, the microflocs and bacteria in the water are almost completely intercepted by the surface of the membrane, 70% of the free anionic surfactant in the water penetrates the membrane pores, and the filtered water C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com