Method for reducing leakage current on surface of base plate in thin film transistor

A technology for thin-film transistors and substrate surfaces, which is applied in the manufacture of circuits, electrical components, and semiconductor/solid-state devices. Reduce stray capacitance and improve electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

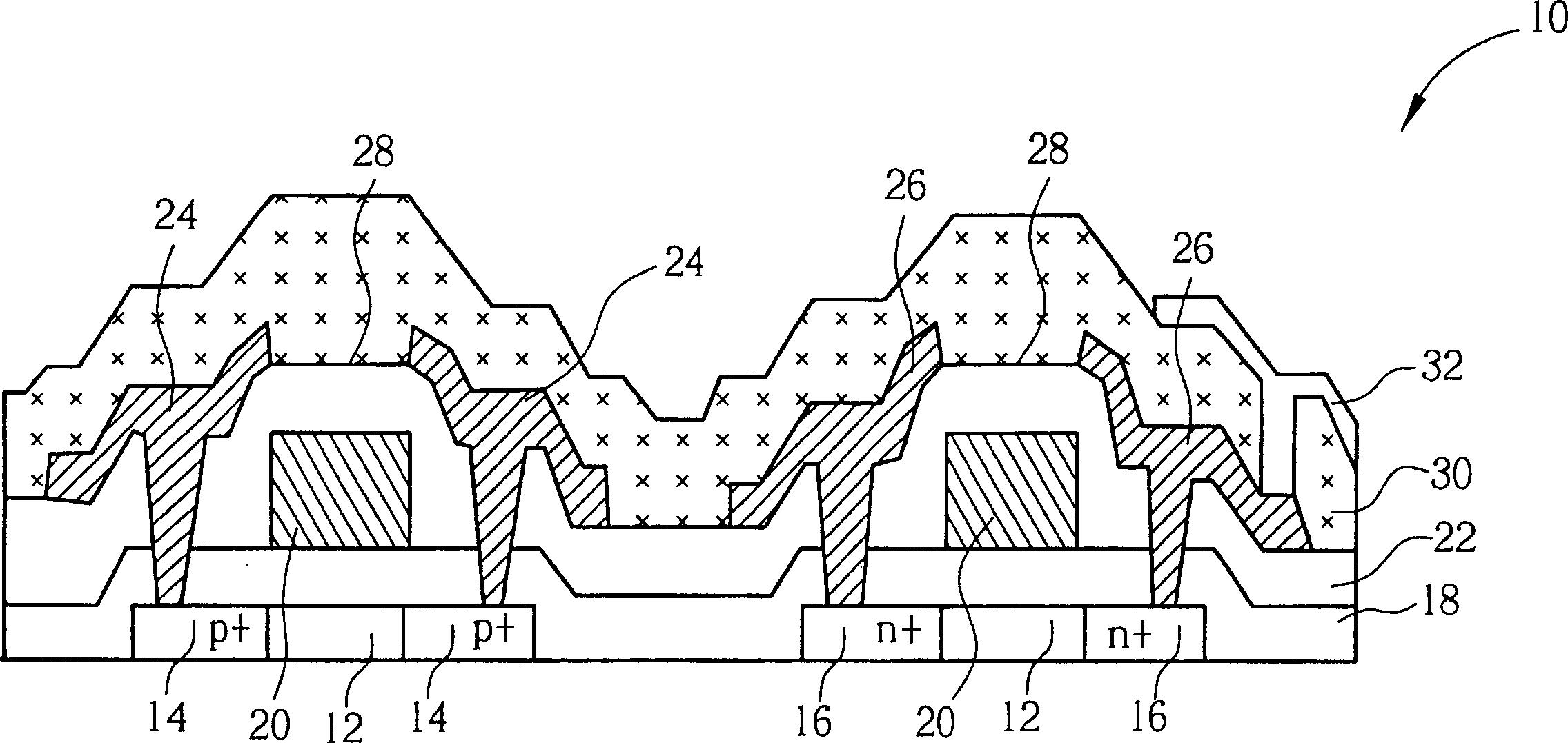

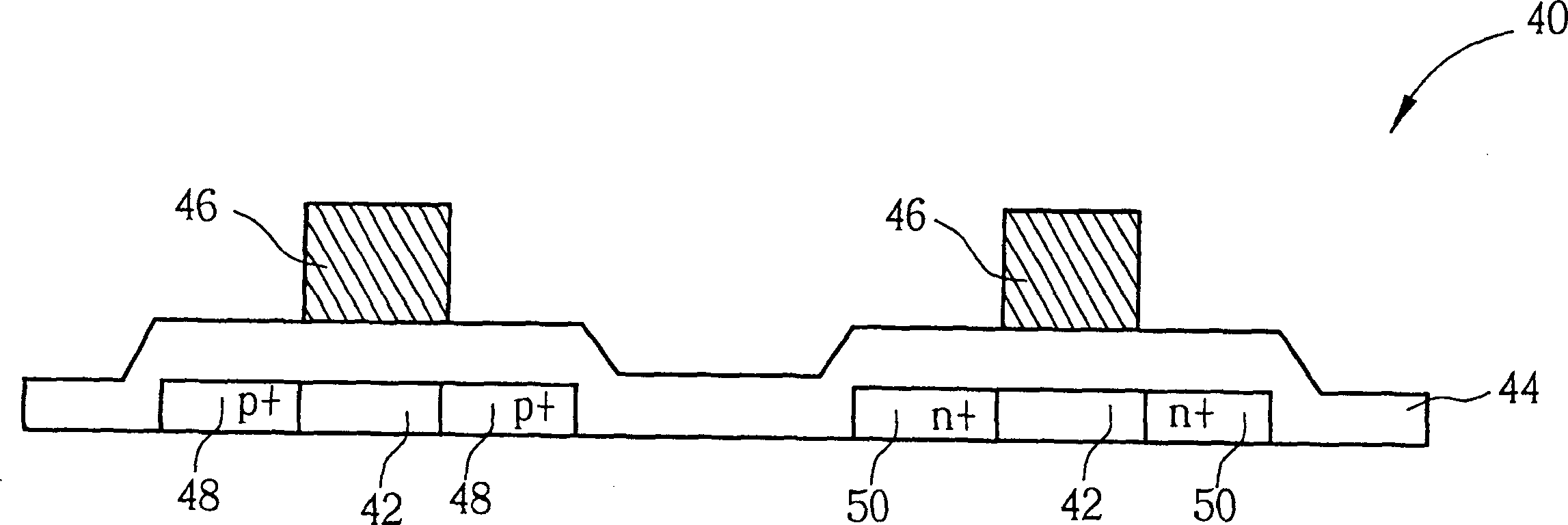

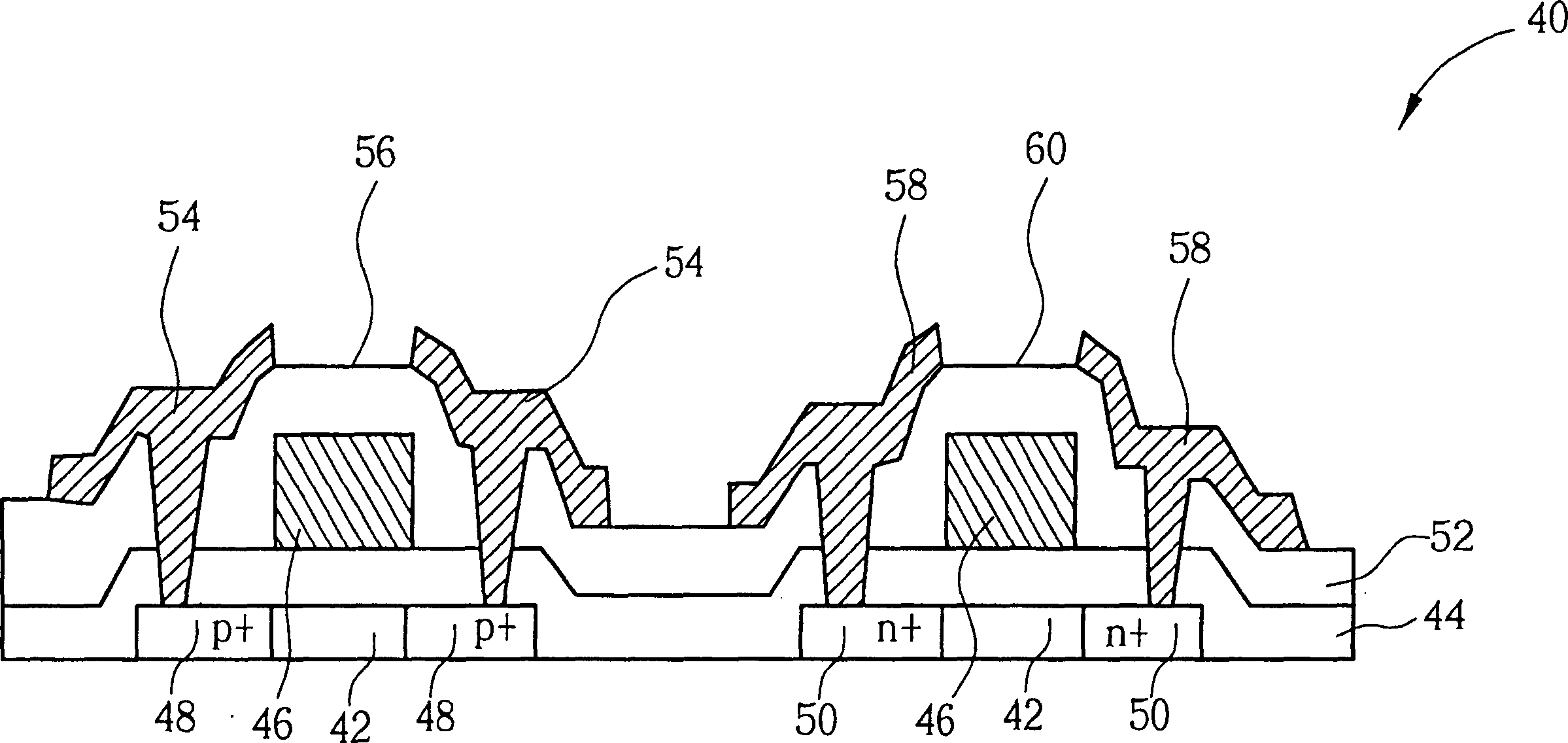

[0023] Please refer to Figure 2 to Figure 5 , Figure 2 to Figure 5 It is a schematic diagram of the method for manufacturing a thin film transistor substrate of the present invention. Such as figure 2 As shown, a semiconductor layer 42 is first formed on the surface of a thin film transistor substrate 40, and then a plurality of doped regions 48 and 50 are formed in the semiconductor layer 42 by using different types of dopants as the source / drain of the thin film transistor. , and define the element type as N-type TFT or P-type TFT. Next, a gate insulating layer 44 and a first metal layer 46 are sequentially formed on the surface of the semiconductor layer 42, and part of the first metal layer 46 is removed by photolithography and etching processes to form a plurality of gates on the semiconductor layer 42. Pole 46. In addition, in other embodiments of the present invention, the gate 46 can also be used as an ion implantation mask after the gate 46 is formed, so as to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com