Method for preparing 3,3-diethoxy ethyl acrylate

A technology of ethyl diethoxy acrylate and ethyl cyanoacetate, which is applied in the fields of medicine and sanitation and organic synthetic chemistry, can solve the problems of inaccurate pH value and practical operation difficulties, and achieve simplified operation process and reduced solvent anhydrous treatment and recovery, the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

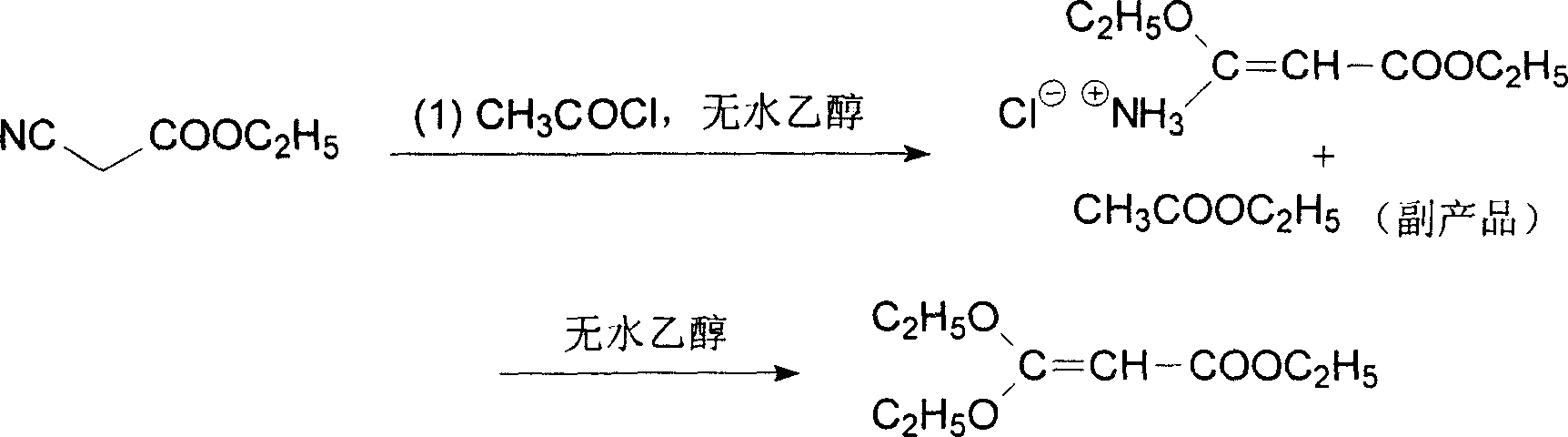

Image

Examples

Embodiment 1

[0015] At -20°C, add 9.8 grams (0.125 moles) of acetyl chloride to a three-necked flask containing 11.3 grams (0.1 moles) of ethyl cyanoacetate and 9.2 grams (0.2 moles) of absolute ethanol, and maintain the temperature After reacting for 72 hours, 23.0 grams (0.5 moles) of absolute ethanol were added to the reaction solution, reacted at 0°C for 7 days, reduced to 9mmHg, and collected fractions at 122 to 124°C to obtain 11.3 grams of colorless liquid. 60%.

Embodiment 2

[0017] At 25°C, add 7.8 grams (0.1 moles) of acetyl chloride to a three-necked flask containing 11.3 grams (0.1 moles) of ethyl cyanoacetate and 11.5 grams (0.25 moles) of absolute ethanol, and maintain this temperature for 24 After 1 hour, add 36.9 grams (0.8 moles) of dehydrated alcohol to this reaction solution again, react for 8 days at 25 DEG C, depressurize to 9mmHg, collect the cut of 122~124 DEG C, obtain 7.5 grams of colorless liquid, productive rate is 40 %.

Embodiment 3

[0019] At 30°C, add 6.5 grams (0.08 moles) of acetyl chloride to a three-necked flask containing 11.3 grams (0.1 moles) of ethyl cyanoacetate and 11.5 grams (0.25 moles) of absolute ethanol, and maintain this temperature for 36 After 1 hour, add 4.6 grams (0.1 moles) of absolute ethanol to this reaction solution again, react for 7 days at 45°C, reduce the pressure to 9mmHg, collect the cuts at 122~124°C, obtain 4.5 grams of colorless liquid, and the yield is 30 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com