Aluminum magnesium containing alloy materials

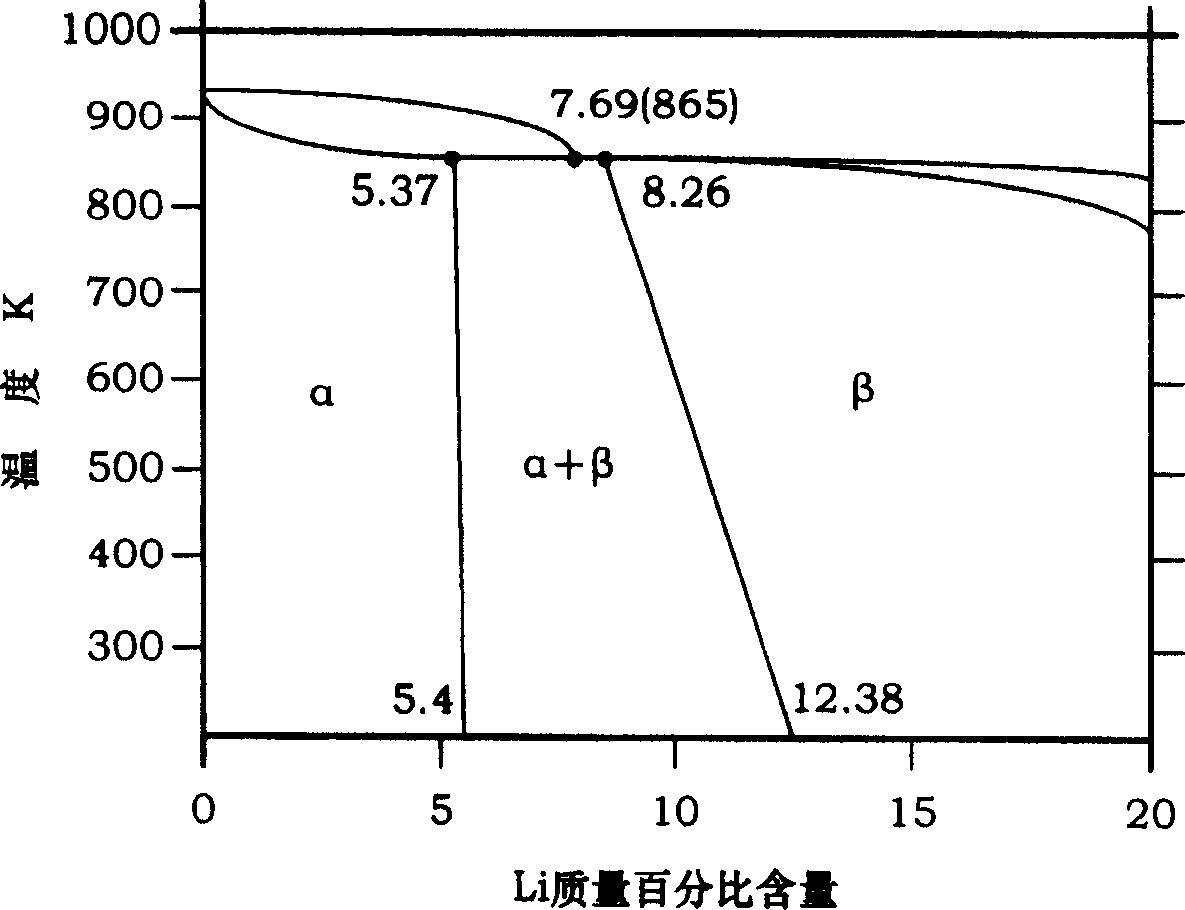

A lithium-magnesium alloy and alloy technology, applied in the field of lithium-magnesium alloy materials, can solve the problems of few β single-phase alloy research reports, no commercial alloy data, poor thermal stability, etc., and achieve good plasticity, low density, high ratio the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The above-mentioned components are prepared by the following preparation method to prepare the lithium-containing magnesium alloy material, and the steps include:

[0016] (1) take out each alloying element by proportioning scale;

[0017] (2) Smelting the alloy by smelting method;

[0018] (3) pouring into ingots under atmosphere protection environment;

[0019] (4) peeling the ingot;

[0020] (5) Homogenize the peeled ingot at 350°C±10°C / 24h;

[0021] (6) Homogenize the homogenized ingot at 430°C±10°C / 48h;

[0022] (7) Deforming the treated ingot at room temperature or at 250°C±5°C to form a product.

[0023] For the performance test of the lithium-containing magnesium alloy material prepared by the above method, the test is carried out with a metal microscope, MTS material mechanical performance testing machine, and one-ten-thousandth balance equipment, and the tensile strength of the lithium-containing magnesium alloy material is σ b =180~280Mpa, the yield stre...

Embodiment 1

[0025] Embodiment 1: prepare 100 kilograms of lithium-containing magnesium alloy materials according to the following proportions, each element that needs to be weighed out is:

[0026] Lithium (Li) 15 kg, aluminum (Al) 5 kg, zinc (Zn) 1 kg, zirconium (Zr) 0.80 kg, rare earth element rhenium (Re) 1.2 kg and the balance of magnesium (Mg).

[0027] The preparation method includes melting the elements taken out of the above scale at a melting temperature of 680°C, and casting them into ingots in an argon-protected environment, peeling the ingots with a machine tool and acid solution to obtain a clean surface, and peeling the ingots to obtain a clean surface. Homogenize the ingot at 350°C±10°C / 24h, and then homogenize the ingot at 430°C±10°C / 48h. Under the condition of ℃±5℃, it is processed into products by forging or rolling deformation.

[0028] The product was kept at a temperature of 250° C. for 4 hours, and then taken out. It can meet the general performance requirements. ...

Embodiment 2

[0029] Embodiment 2: prepare 100 kilograms of lithium-containing magnesium alloy materials according to the following proportions, each element that needs to be weighed out is:

[0030] Lithium (Li) 10 kg, aluminum (Al) 4.5 kg, zinc (Zn) 1 kg, zirconium (Zr) 0.80 kg, rare earth element rhenium (Re) 1.2 kg and the balance of magnesium (Mg).

[0031] The preparation method includes melting the elements weighed out above at a melting temperature of 720°C, and melting them in SF 6 The ingot is poured into an ingot under the protection environment of a mixed gas, and the ingot is peeled with a machine tool and an acid solution to obtain a clean surface, and the peeled ingot is subjected to a homogenization treatment at 350°C±10°C / 24h. The ingot is homogenized at 430°C±10°C / 48h, and the homogenized ingot is processed into products by forging or rolling at room temperature or at 250°C±5°C.

[0032] The product was kept at a temperature of 250° C. for 4 hours, and then taken out. It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com