Structure of mask ROM and method for manufacturing the same

A technology of read-only memory and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve data errors in read-only memory storage units, poor product reliability, and affect storage unit operating characteristics, etc. problems, to achieve the effect of reducing production costs and reducing delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

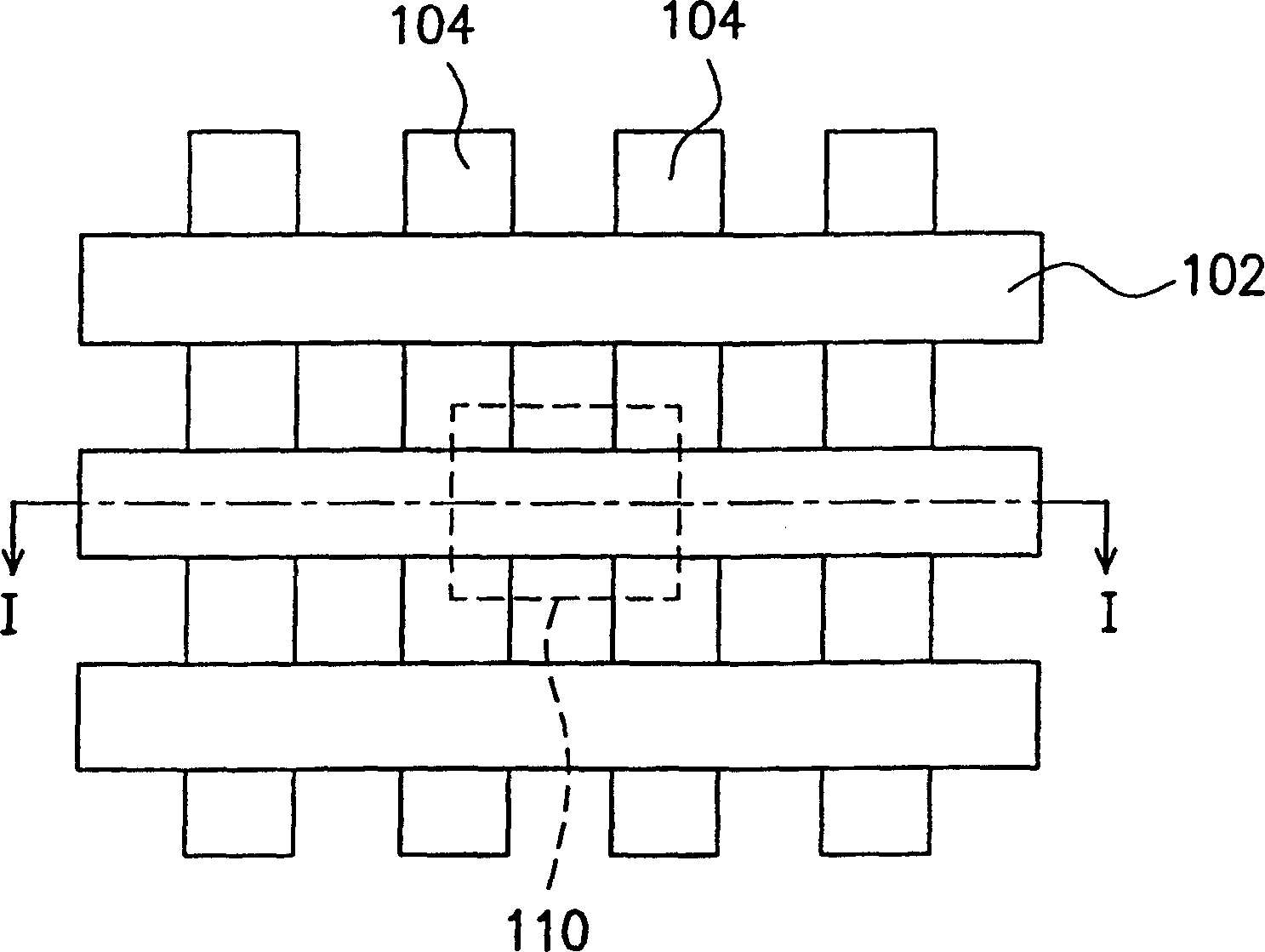

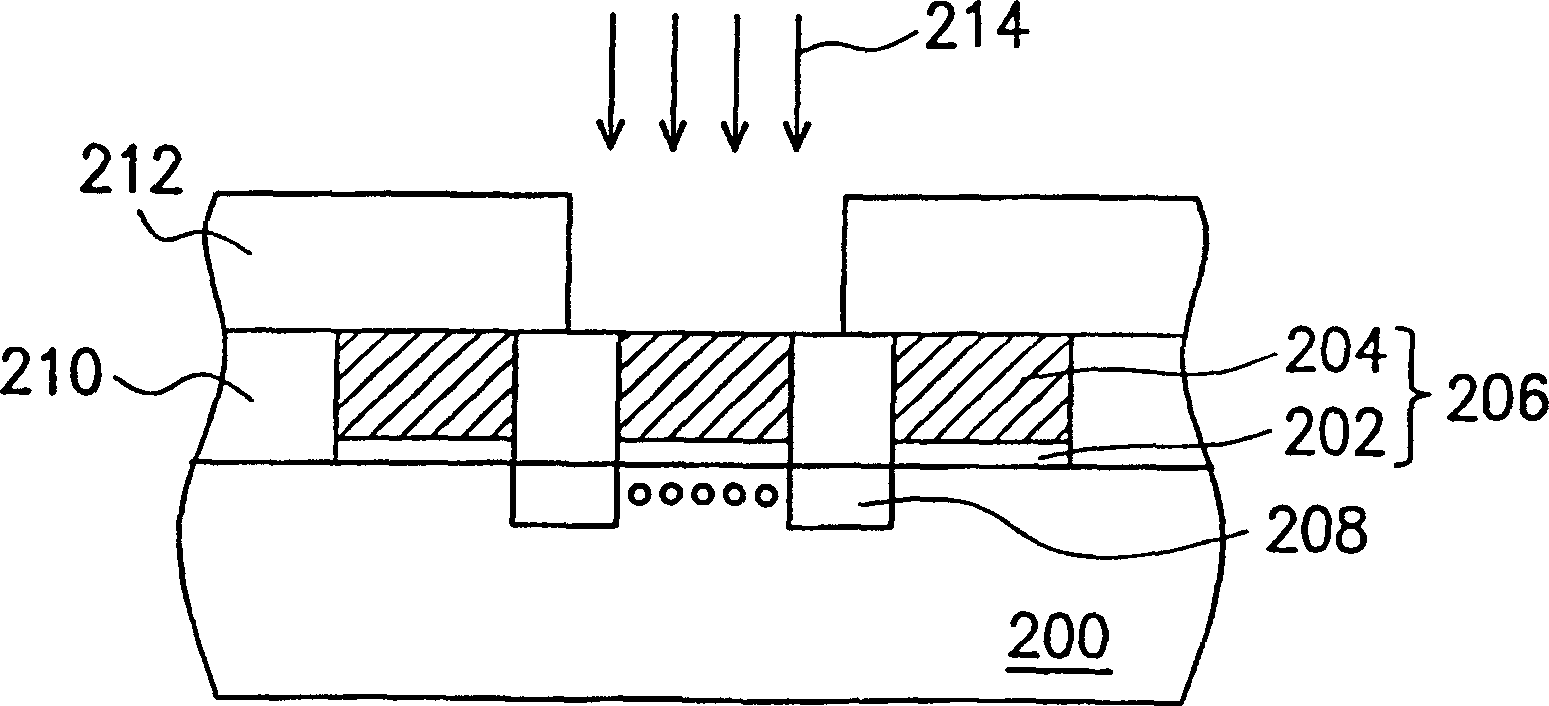

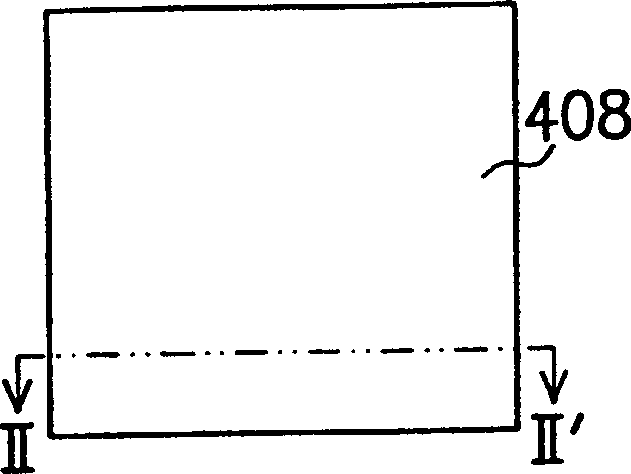

[0047] The invention provides a structure of a mask-mode read-only memory and a manufacturing method thereof. Figure 3A to Figure 3G It is a top view of a memory cell region of a mask-mode ROM according to an embodiment of the present invention. Figure 4A to Figure 4G It is a sectional view of a manufacturing process of a mask-mode ROM according to an embodiment of the present invention. exist Figure 4A and Figure 4G The middle substrate 400 can be divided into a memory cell area 402 and a peripheral circuit area 404, wherein the memory cell area 402 shown in each figure is respectively Figure 3A to Figure 3G The cross-sectional view of the structure along the line II-II'.

[0048] First, please refer to Figure 3A and Figure 4A , providing a substrate 400, such as a semiconductor silicon substrate. The substrate 400 can be divided into a memory cell area 402 and a peripheral circuit area 404 .

[0049] Next, a plurality of isolation structures 406 are formed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com